System checks, Warning, Diagnostic chart – Atwood Mobile Products Model 8940 User Manual

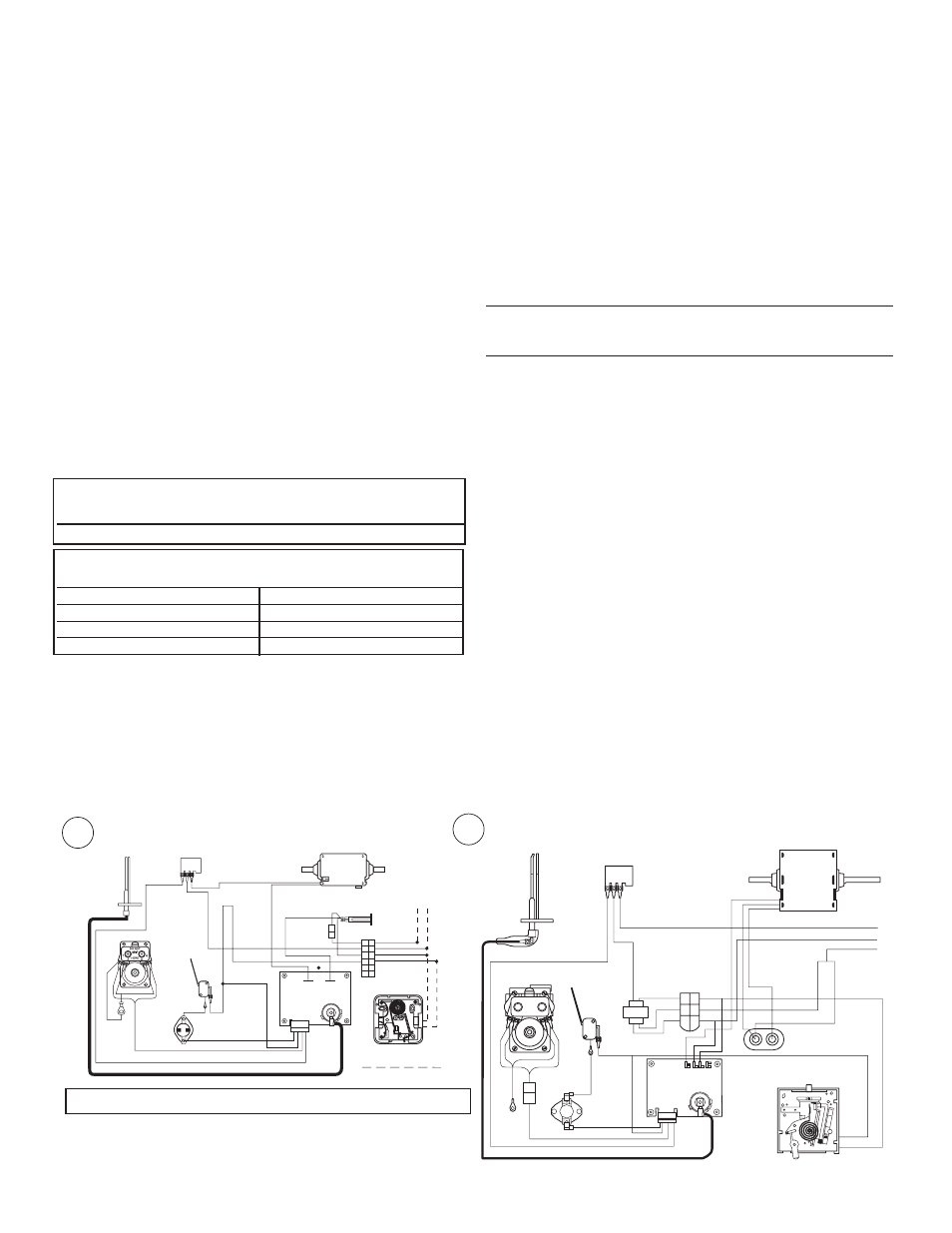

Page 5: Propane gas pressure test, Static pressure test, Remove rain shield by tilting as depicted in, Never check for leaks with an open flame, Dc wiring diagram ac wiring diagram, Fire or explosion

5

3. A. When set for LP and NAT is required:

Rotate plug and replace into valve tower.

NAT

SHOULD NOW BE VISIBLE FIG

5

B. When set for NAT and LP is required:

Rotate plug and replace into valve tower.

LP

SHOULD NOW BE VISIBLE FIG

5

4. Check rod for proper positioning while tightening plug into tower.

The plug, which has been factory calibrated for this valve only,

should be reinstalled finger tight.

DO NOT USE PLUG ON ANY OTHER VALVE

.

INSTALL ONLY THE CORRECT MAIN BURNER ORIFICE FOR TYPE OF GAS BEING USED

.

ORIFICE REPLACEMENT

1. Remove rain shield by tilting as depicted in

FIG

9 insert.

2. Remove burner assembly from control box.

3. Remove two screws holding burner head in place.

4. Use a 7/16˝ socket to remove orifice and replace correct orifice cor-

responding to type of gas required, which corresponds to regulator

plug setting

FIG

5.

5. Replace burner head with two screws.

6. Reinstall burner assembly. Burner assembly must seal tight against

control box.

7. Replace rain shield and four screws.

8. After converting furnace,

IN PLAIN SIGHT

, put “

CONVERTED

” sticker (pro-

vided in your conversion packet) on rating label.

SYSTEM CHECKS

ƽ

WARNING

FIRE OR EXPLOSION

• Never check for leaks with an open flame.

DIAGNOSTIC CHART

FAULT

LED INDICATION

Internal Circuit Board Failure

Steady on, no flashing

Limit switch/Airflow problems

1 flash with 3-second pause

Flame Sense Fault

2 flashes with 3-second pause

Ignition Lockout Fault

3 flashes with 3-second pause

PROPANE GAS PRESSURE TEST

The furnace and any individual shut-off valve must be disconnected

from gas supply piping system during any pressure testing of system

at test pressures of more than 1/2 PSI.

Before furnace is connected, piping systems must be tested to be leak

free. The test must maintain air pressure of at least 6˝ of mercury or 3

PSI for at least 10 minutes.

The entire piping system must be maintained within a range of 10-14˝

W.C. when all appliances are in operation. Test the gas connections for

leakage with a leak test solution.

STATIC PRESSURE TEST

(

FIG

.

1)

CASING STATIC PRESSURE TABLE

If duct static pressure cannot be set, casing static pressure should not exceed

the values listed below when taken cold.

DUCTING SYSTEM

OPERATING VOLTS

FLEXIBLE

HARD

DC

MODELS

12

0.25˝ W.C.

0.35˝ W.C.

AC

MODELS

120

0.25˝ W.C.

0.35˝ W.C.

NOTE

: For maximum performance and reliability refer to Installation Addendum

for manufacturer’s recommendations and specifications.

Voltage greater than indicated will cause higher static readings.

Reducing the number of duct turns and stretching ducts will increase

air flow and reduce static pressure. Adding ducts or increasing dis-

charge system (hard ducting) will also reduce static pressure.

1. With door open, locate static pressure tap or use location on back of

casing

FIG

1.

2. Shut off gas supply to furnace.

3. Insert static pressure tube onto tap and attach an incline manometer.

With door closed, pressure should not exceed values specified in

CASING STATIC PRESSURE TABLE

.

4. Remove pressure tube when finished. Close door or reinstall cover.

12V DC

SUPPLY

IMPORTANT: If any original wire has to be replaced, it must be replaced with type 105 C or its equivalent.

Terminal Block on 85 Models only.

BLACK

BLUE

RED

YELLOW

HIGH TENSION

+ 12V DC

NEG

RED

YELLOW

ELECTRODE

YELLOW

VALVE

RED

1

4

2

5

3

6

1

4

2

5

3

6

+THERMO

MOTOR

CIRCUIT

BREAKER

IGNITION

BOARD

BLW PWR

SAIL

SWITCH

BLUE

BLUE

LIMIT

SWITCH

WHITE

BLUE

YELLOW

RED

GROUND

THERMOSTAT

ON

OFF

ON/OFF

SWITCH

THERMO

DC Wiring Diagram

AC Wiring Diagram

RED

11

12

CUSTOMER SUPPLIED WIRING

PICTORIAL DIAGRAM

Off

On

Valve

Electrode

Green

Sail

Switch

Green

Yellow

3 3

2 2

1 1

White

Black

Yellow

Black

Black

Yellow

Red

Blue

Blue

Limit Switch

Blue

Red

Green

Yellow

Transformer

Ignition Control

Black

Brown

Motor

120 VAC Green

120 VAC Black

120 VAC White

White

Thermo Blue

AC Capacitor Motor Run

+Thermo Blue

HIGH TENSION

DO NOT

GRIP

HERE

1

4

2

3

+

+

1 2 3 4 5 6

NOTE: Circuit Breaker and ON/OFF Switch may be

separate or combined components.