Technical information upgrades, Limited warranty, General safety – Quick Cable Hex Crimp Jr. User Manual

Page 2: Maintenance, Replacement parts, Pur 71, Pur 71 ratchet option

Technical Information Upgrades

Copyright © Quick Cable Corporation. Quick, Quick Cable, HexCrimp, Bench Crimp, QuickCutter and the

Quick Cable logo are trademarks of Quick Cable Corporation. All rights reserved.

X1189B

We are continually upgrading our tool line. For all current information

visit our website: http://www.quickcable.com

Limited Warranty

Quick Cable Corporation manufactures the highest quality tools to exacting

engineering standards. Quick Cable will replace any Quick

®

Crimper and

HexCrimp Jr.

®

Crimper found to be defective and returned within two years of

date of purchase. Quick Cable will replace any Cub Crimper found to be de-

fective and returned within one year from date of purchase. Quick Cable will

replace any Brute

™

Hammer Crimp found to be defective & returned within six

(6) months from the date of purchase. Quick Cable will replace any cutter

found to be defective & returned within six months from date of purchase.

This warranty replaces all other warranties. Replacement of defective products

is your exclusive remedy. Quick Cable is not responsible for injury, property

damage, or the consequential damages arising either directly or indirectly from

the use of our products, even though that injury, property damage or other

consequential damages may have been directly or indirectly caused by an

actual defect in materials or workmanship.

We like to know how our products have performed for you. We welcome your

comments and suggestions regarding our products, their installation or per-

formance. Contact us at: Quick Cable Corporation - 3700 Quick Drive

Franksville, WI 53126-0509

Maintenance

Quick Cable crimpers are factory lubricated with low friction, high temperature,

synthetic lubricant. Additional lubrication may be required for very high usage tools.

Simply add two or three drops of #30 weight oil to each pivot point. Circulate the oil

by opening and closing the tool several times.

Replacement Parts

Dies, springs, snap rings and hardened hex pins are all available, just ask your distributor.

OIL

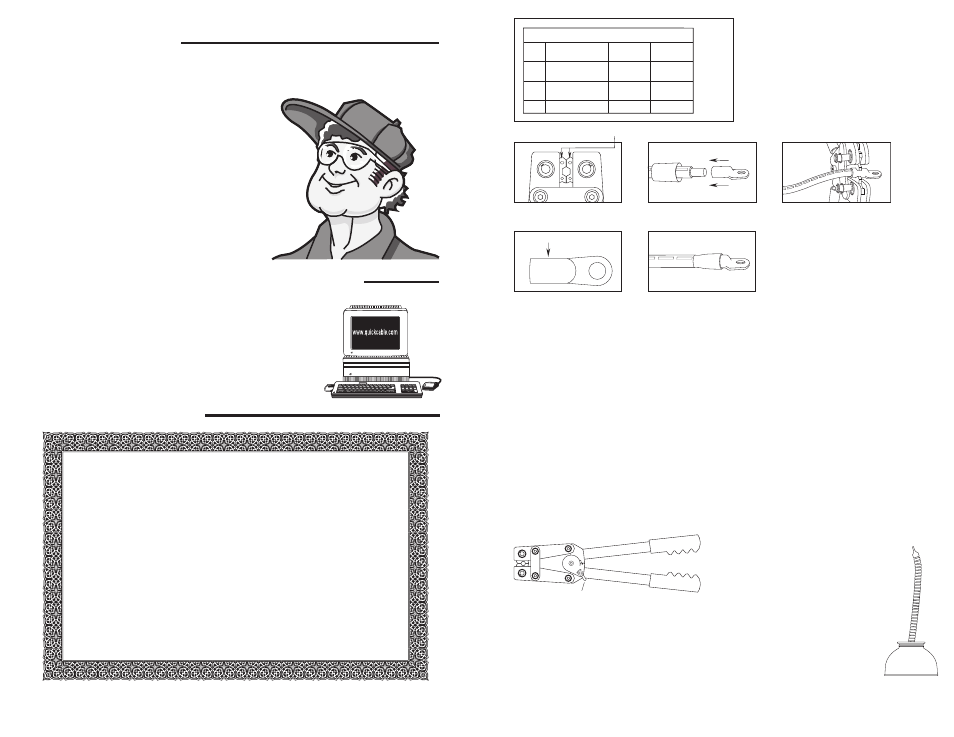

Fig. 3 - Slide heat shrink on

first

Fig. 1 - Die setting chart

Fig. 4 - Position connector in

dies

Fig. 5 - Crimp lug

Crimp

Fig. 6 - Shrink on tubing

General Safety

1. Batteries produce hydrogen gas which could explode if there is a spark near the battery.

Never work leaning over a battery. Do not have a flame near a battery. Do not smoke.

Wear eye protection.

2. Batteries contain sulfuric acid which is corrosive

and lead which is poisonous. Many battery

connectors are made of lead or have a lead coating.

Wash your hands thoroughly after installation. Do

not allow children to play with batteries, battery

cables or connectors.

1. Using the chart on the tool, determine the proper die setting for the gauge of cable and

style of connector. Fig. 1

2. To select the dies, push the die pivot pins from the spring side and rotate both dies to the

proper setting. Releasing the pivot pins locks the dies in place. Fig. 2

3. Strip cable insulation 3/4" for copper tube lugs so that the bare conductor seats fully in the

connector. If you are using heat shrink tubing, slide it over the cable before applying the

connector. Fig. 3

4. Open tool and position connector in crimp dies. Fully close dies for proper crimp. Fig. 4

5. Crimp a minimum of 1/8" in from the barrel end. Fig. 5

6. For best results, protect each termination with Quick Cable heat shrink tubing. Fig. 6

Cable

Gauge

8

6

4

2

1

GREY 25

GREY 25

GREY 25

PINK 30

PINK 30

GREY 16

GREY 16

BROWN 20

WHITE 14

PINK 30

RED 10

RED 10

GREY 16

GREY 25

GREY 25

Cast Copper Battery

Terminals and Lugs

MagnaLugs

100% Copper

Copper

Tube Lugs

CAUTION:

Do not

crimp 1/0

Ga. battery

connectors

with this

tool. See

instruction

sheet for

safety

information

Crimp Die Settings

Fig. 2 - Push pin, rotate dies

Die settings

PUR 71

PUR 71

Ratchet Option

The ratchet mechanism is designed to ensure the best possible crimped connection. The

ratchet mechanism requires the operator to complete the full crimp before it will release. If

required, the ratchet mechanism can be disengaged by moving the release pawl (see picture)

towards the handle.

Pawl release