Woodhead T-TORQUE REEL User Manual

Page 3

SM142001A

Page 3 of 6

©Aero-Motive Sep-99

SPRING REPLACEMENT

DANGER:

To prevent personal injury, death or property damage, handle all springs which are

potentially dangerous with care. Immediate hazards WILL result in severe personal

injury or death.

DANGER:

To prevent personal injury, death or property damage, hold the center of the spring

down as the hub is pulled out. If the center is allowed to rise up, the spring may escape

from its container. Immediate hazards WILL result in severe personal injury or death.

NOTE: This reel contains two to five springs. If one of them has broken due to fatigue, it is recommended that

all springs be replaced to avoid excessive down time, since they have been subjected to the same wear, and

may be near the breaking point.

First, with cable fully retracted, remove tool clip. Release all tension by turning adjustment nut counter-

clockwise. Move reel to a bench or convenient work area. Place reel on a bench with tension nut side

down, so that the reel is level. Remove six nuts from end plate and remove end plate. Remove cable

drum assembly. Remove the cable assembly by removing set screw. Remove the band assembly. Remove

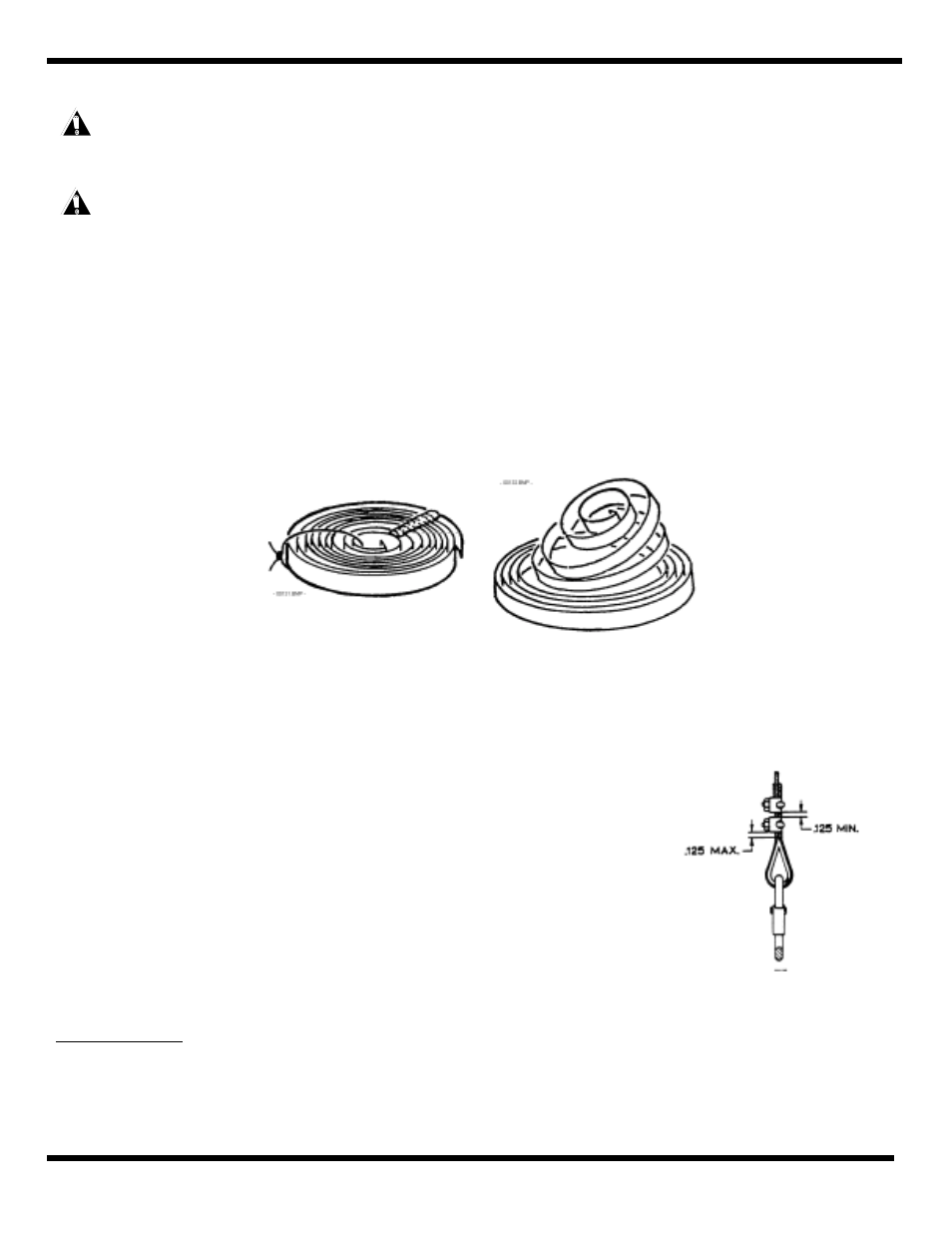

the spring and cup assembly and subsequent spring and cup assemblies. Spring assemblies must be

removed carefully from the shaft. When removing spring assembly, carefully grasp spring and cup so that

the spring remains in the cup.

When disposing of old or broken spring assemblies, the coils should be welded or wired securely together to revent

possible injury to scrap handling personnel. DO NOT allow the center of the spring to raise.

If spring hub comes off the shaft with spring cup, place hub in new spring assembly, making sure that the

hub is engaging the spring. Replace broken spring assembly and reassemble the reel by following steps

above in reverse order. When replacing spring assemblies make sure that the square projection, on the end

of spring hub, is properly engaged in the opening in the spring cup. Before replacing reel make sure that

all nuts, bolts, and cotter pins are replaced. Pretension reel as described above. For lubrication: See

MAINTENANCE.

LOWER HOOK REPLACEMENT

If for any reason the lower hook must be replaced, thimble and clamps must

be replaced as shown in the short end of the cable. On the side of clamps,

shrinkable tubing or electrical tape should be placed around cable ends to

prevent injury of the frayed strands.

MAINTENANCE

LUBRICATION

The spring and bearings have been sufficiently lubricated at the factory to last the normal life of the reel.

If grease has been removed during maintenance, it should be replaced with good quality, high-low,

temperature grease (Texco AFB 2 or equal). Bearings should be packed, and springs should have enough

grease in the cup to thoroughly coat the entire spring as it works in during use.