Woodhead LA Balancer Serie User Manual

Page 4

SM1160-01B

Page 4 of 7

©Aug-01

LOWER HOOK REPLACEMENT

CAUTION:

After securing sleeve, tape may be placed around cable end to prevent injury on frayed

strands. Hazards or unsafe practices MAY result in minor personal injury or product or

property damage.

NOTE: Clamps are used for models xxxLA01 only. A swage-fitting sleeve should be used for all other models.

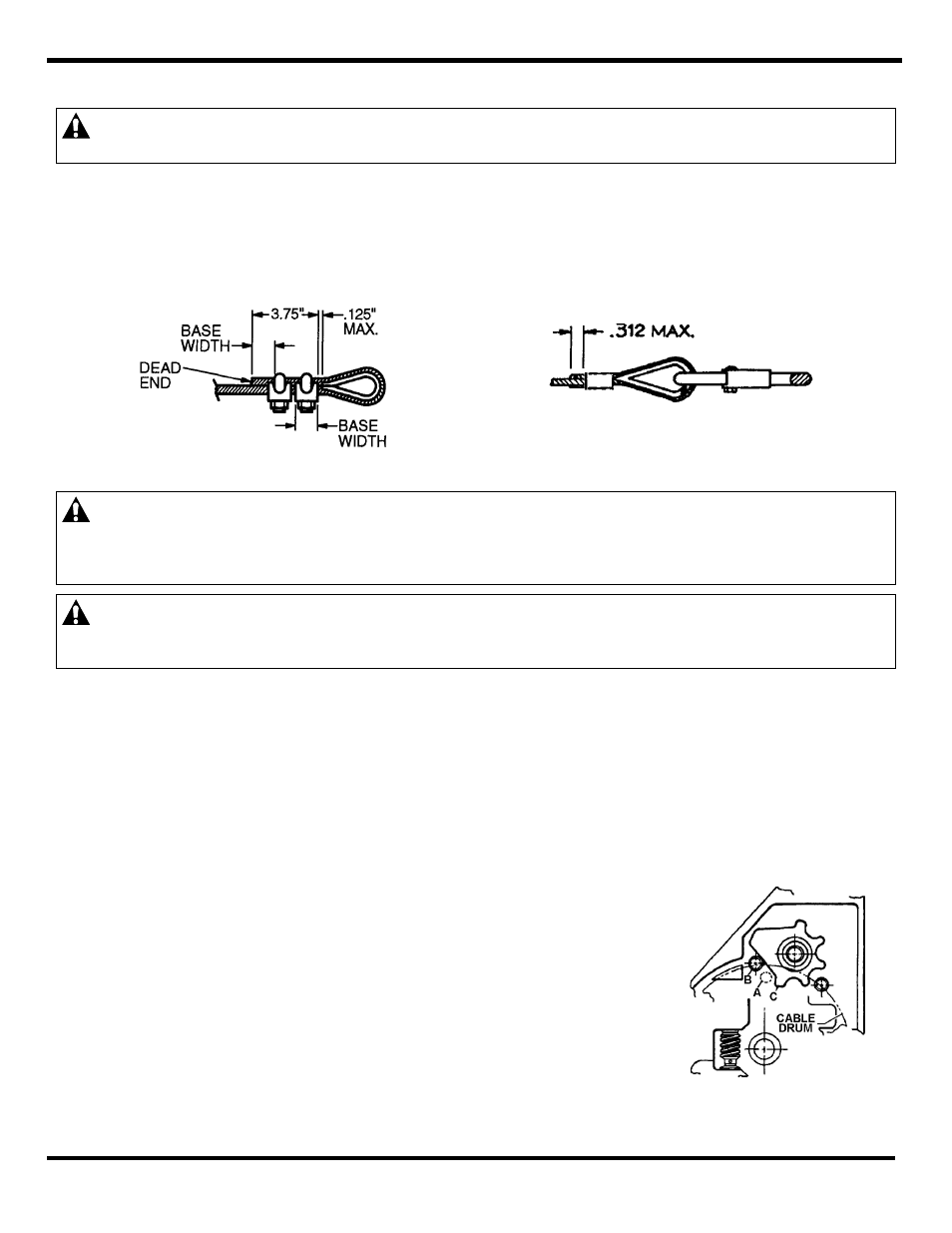

If lower hook is removed or replaced for any reason, the thimble and clamps (or sleeve) must be

replaced as shown in illustration. If clamps are used, turn back 3 ¾ inch of rope from thimble. Apply u-

bolt over dead end of wire rope - live end rests in saddle. Tighten nuts evenly, alternating from one nut

to the other until reaching recommended torque (7.5 ft-lbs.). Apply second clip as near the thimble as

possible. Tighten evenly, alternating until reaching recommended torque (7.5 ft-lbs.).

MAINSPRING REPLACEMENT

WARNING:

Never under any circumstances remove spring from its sheet metal cartridge.

Replacement springs are assembled in a sealed cartridge for safety and there is no need

to remove them. Removal of spring from its cartridge lead to hazards or unsafe practices

which COULD result in severe personal injury or death.

CAUTION:

Before removing mainspring, remove all tension from balancer by turning tension

adjustment nut counterclockwise until all tension is released (ref. Spring Tension

Adjustment). Hazards or unsafe practices which MAY result in minor personal injury or

product or property damage.

Remove the balancer from service and remove the two hanger bracket pins and the two cable guide

screws. The spring cover can now be removed by loosening six bolts. Remove the four bolts that hold

spring cartridge to drum. This will allow the spring cartridge assembly to be removed from the drum and

pulled off over the main shaft. The entire cartridge (containing three springs) must be replaced with a

new or rebuilt unit. Remove the old bearing from the spring cover and replace with new one.

Reassemble in reverse order and add enough tension to retract safety lock fingers on the spring cartridge

as described in Spring Tension Adjustment. Reinstall spring cover and complete tensioning.

NOTE: To align the springs with spring hubs, it may be necessary to rotate the spring assembly back and forth

slightly as the spring assembly is pushed back onto the shaft.

STAR WHEEL POSITIONING

If drum has been removed during service, it is very important to

Position star wheel properly when reassembling balancer. If this is not

done, drum will be “out-of- time” and will either fail to return or extend

The full distance of cable travels. When reassembling, with cable off

the drum and when viewed from the spring side of housing, the star

wheel must be positioned as shown in relation to pin (B). The pin on

the cable drum (A) must be positioned as shown in relation to point (C)

on star wheel.