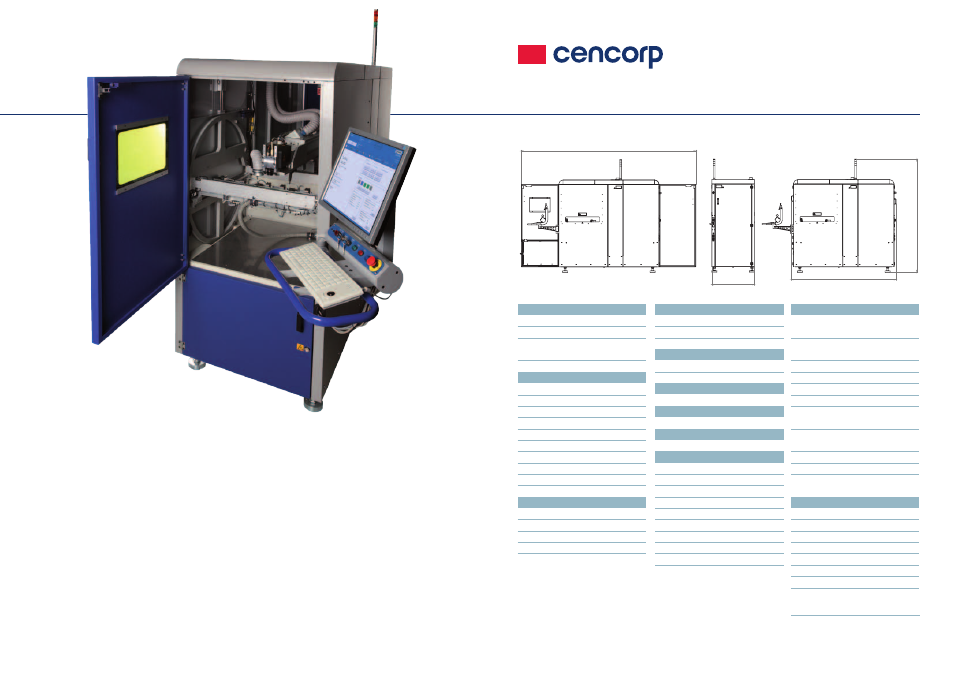

Cencorp 700 lm, Technical data – Cencorp 700 LM – PCB LASER MARKER User Manual

Page 2

Efficiency and flexibility for your circuit

board marking with Cencorp 700 LM

Flexible laser marking solution

Cencorp 700 LM laser marking cell is the

solution for your cost efficient laser marking

needs. With different options it can also

be tailored to your advanced marking or

markings removal requirements. Cencorp 700

LM can also be equipped with a flip conveyor,

making 2 side marking easy to handle in a

single process.

The best choice for low cost automated

marking

When you are looking for a solution which

ensures that the marking is not a bottleneck

in your production in terms of a Quality, Cycle

time, Change-overtime and Maintenance - this

machine is your choice!

CENCORP 700 LM

TECHNICAL DATA

Machine Dimensions

Laser unit technical spec.

Electrical Service Requirements

Board Handling

Pneumatic Service Requirements

Laser unit software

Options

Environmental Requirements

Machine Control

Base Standards

Graphical User Interface

Software for marking of vector and

raster graphics

Operating temperature: 17… 28 °C (63… 82°F)

PLC: OMRON

Light tower

PC with a keyboard and display

Operating humidity (r.h.): 30% … 85%

Voltage EU (USA): 230 (110) VAC10%

Internal board flip

Creation of Bar Codes and Data Matrix

(solid cells or dots)

Import formats for vector graphics:

plt, dxf, cmx, emf, svg, ai, job, mcl

Pressure: 5-7 bar (73-100 PSI)

Width: 750mm (29.5”)

X-Y axis: 516 mm x 480 mm

Programmable conveyor width adjustment

Connection to customer database

Sequenced marking

Line width setup with beam deflection

Approx. air consumption: 20 l/min

Average power: 30W

Height: 1640mm (64.5”) without beacon,

1980mm (78.0”) with beacon

Scanner area: 105 mm x 105 mm

Branch circuit size: 10A

Average power consumption: 500VA

Programmable Z-axis

Fiber laser

True type fonts

Import formats for bitmap graphics:

bmp, jpeg, gif, tiff, tga, png, pcx

±10%, dry clean air

Depth: 1841 mm (72,5”)

Programmable Z-axis: 70mm

Frequency EU (USA): 50 (60) Hz

Camera for fiducial alignment

Internal fume extraction unit

Monochrome marking on bitmap graphics

Arc text

Weight: 1000kg (2205 lbs)

Max PCB size: 516 x 480 mm (LxW)

Transfer protocol: SMEMA

PCB Thickness: 0.6-4.0 mm

Bottom clearance: 10 mm

Adjustable conveyor width

Transfer height: 900 ±30 mm

PCB transfer time: < 4 s

Top clearance: 70 mm

Edge clearance: 3 mm

Min PCB size: 50 x 70 mm (LxW)

Optionally other configurations are

available, consult the nearest Cencorp

representative.

Camera for 2D code quality check

Other options upon request

Possible to combine vector and raster graphic

Date format selection with automatic

update fuction

Standard:

Active media: CO2

Wavelenght: 10600 nm

Main dimensions:

Specifications subject to periodic review and change without notice

Providing flexibility and efficiency

Cencorp has a long experience in laser processes and

the 700 LM laser marker is the result of extensive

product development. The core unit meets the

basic marking requirements but it can also be fitted

with different options to meet the most advanced

requirements. This approach is also a cost-effective

and efficient solution for your individual marking

needs.

Platform & module strategy

Our standard solutions are based on one platform

and module strategy. If required, customer specific

modules can be created to meet the marking process

requirements. In effect, more process power can be

packed in a smaller space.

3074

748

1840

1988,50