Karcher IB 15-80 User Manual

Page 18

-

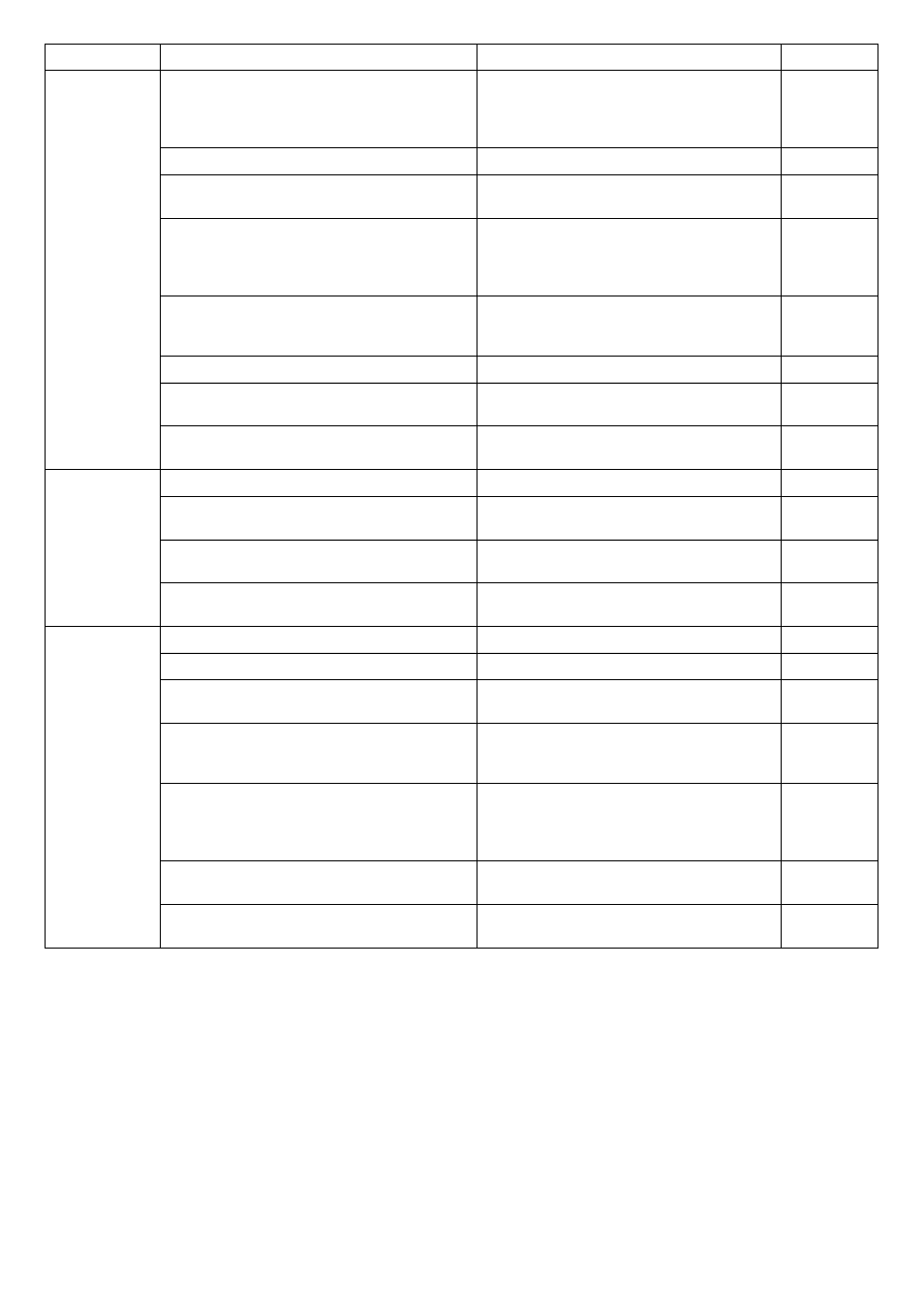

7

Fault

Possible cause

Remedy

By whom

No compressed

air jet despite the

trigger being

drawn

Compressed air supply has too little pressure

Check pressure level.

Turn the adjusting knob for dry ice dosing to

"OFF", wait 1 minute and and then switch the

device back on and set it to the desired value.

Operator

Jet pressure is set too low

Set the jet pressure to a higher level.

Operator

Power supply has been interrupted

Check power supply. Indicator lamp "Device on"

must glow.

Operator

Emergency-stop button has been pressed.

Release emergency-stop button by pulling it.

Turn the adjusting knob for dry ice dosing to

"OFF" and then set it again to the desired value.

Indicator lamp "Device on" must glow.

Operator

Control cable not connected properly

Check connection between control cable and

the jet pistol and between the control cable and

the device.

Operator

Control cable is defective

Replace spray agent hose.

Operator

Pressure switch is defective

Replace pressure switch.

Customer

Service

Solenoid valve is defective

Replace solenoid valve.

Customer

Service

Compressed air

jet is too weak

Jet pressure is set too low

Set the jet pressure to a higher level.

Operator

Compressed air supply has too little pressure or

the compressor output is low.

Check pressure and output.

Operator

The filter inlay in the water separator attachment

(accessory) is blocked.

Replace the filter inlay in the water separator.

Operator

Spray agent hose or jet pistol is blocked

Let the spray agent hose and jet pistol come to

room temperature and remove the blocking.

Operator

No dry ice pel-

lets in the com-

pressed air jet

Operating type switch is positioned at "1"

Set operating type switch to position "2".

Operator

Dry ice container is empty

Refill the dry ice container

Operator

Dry ice has melted

Empty the dry ice container and refill it with fro-

zen dry ice pellets.

Operator

Vibrator on the dry ice container is not working

The pressure display on the manometer of the

pressure reducer must display 0.5 mPa. Reset

the pressure reducer, if required.

Operator

Drive motor of the dosing equipment is overload-

ed

Press emergency-stop button, wait for 30 sec-

onds, release the emergency-stop button again.

Turn the adjusting knob for dry ice dosing to

"OFF" and then set it again to the desired value.

Operator

Compressed air is exiting into the dry ice contain-

er

Clean the pressure balance channel in the dos-

ing equipment.

Customer

Service

Dosing disc in the dosing unit is defective

Replace the dosing disc.

Customer

Service

18

EN