Important – Air King Vacuum Cleaner User Manual

Page 8

13.

filter Bag - Clogged (some models) - Read the Operations section of this manual for information on

how to remove and clean your filter bag.

14.

dirt Canister Lid - Off - On those models with lift off dirt canister lids, (check the Operations section

of this manual) the lid must be replaced squarely on top of the canister or it will allow a vacuum leak.

15.

dirt Canister Gasket - Loose - If the dirt canister gasket has been pulled loose, it will allow a

vacuum leak. The gasket may be reattached with contact cement or any of the so called “super glues”.

16.

Outside Exhaust - Blocked - Check the exhaust system by removing the tubing from the motor

blower exhaust and comparing the airflow at this point versus the airflow reaching the outside. If

blockage is detected and cannot be removed, contact you service technician.

17.

dirt Canister - Not attached - If the dirt canister latches (some models) are not properly closed, it

will cause an air leak along the gasket and reduce your cleaning ability.

18.

another Wall Inlet door - Open - Check all the inlet valves to make sure that only one inlet is in use

at a time. Attempting to clean from two or more inlets at a time will reduce the airflow below the level

required to deep clean your carpets.

19.

Motor protection Screen - Clogged - This usually occurs due to allowing the dirt canister to over

fill, or a broken filter bag (some models). Refer to the Operations section of this manual for instructions

on cleaning the blower protection screen.

20.

relay Stuck - On - Refer to Number 9. If after using the procedures described in Number 9 it appears

that the relay is sticking on, unplug the power cord to cut off all electricity to the power unit. Caution:

Checking the wiring in the power unit should only be attempted by a qualified service technician.

21.

relay Stuck - Off - If the procedures described in Numbers 1, 2, 3, 4, 5, 6 or 7, do not correct the

power unit not starting, then it could be a malfunction of the relay, the low voltage transformer could

be burned out, or there could be a loose wire in the power unit. If you suspect a malfunction in the

power unit, contact your service technician.

22.

Transformer - Burned Out - Refer to Number 21.

23.

Loose Wire In the power Unit - Refer to Number 21.

24.

a hose plugged Into another Inlet Valve - Cleaning from more than one inlet at a time will reduce

the airflow to less than is required to deep clean your carpets.

25

.

p.C. Board relay stuck on - Refer to Number 9. If after using the procedures described in

Number 8 it appears that the relay is sticking on, unplug the power cord to cut off all electricity to

the power unit. Caution: Checking the wiring in the power unit should only be attempted by a qualified

service technician.

26

.

p.C. Board Transformer burned out - If the procedures described in Numbers 1, 2, 3, 4, 5, 6 or 7,

do not correct the power unit not starting, then it could be a malfunction of the relay, the low voltage

transformer could be burned out, or there could be a loose wire in the power unit. If you suspect a

malfunction in the power unit, contact your service technician.

27.

LEd Light- Some units have an LED light at the unit. If the LED light is not on, refer to number 5. If you

have power at the unit but LED light is off, contact your local service technician.

If YOU CaNNOT dIaGNOSE Or rEpaIr YOUr TrOUBLE, CONTaCT ThE NEarEST dISTrIBUTOr.

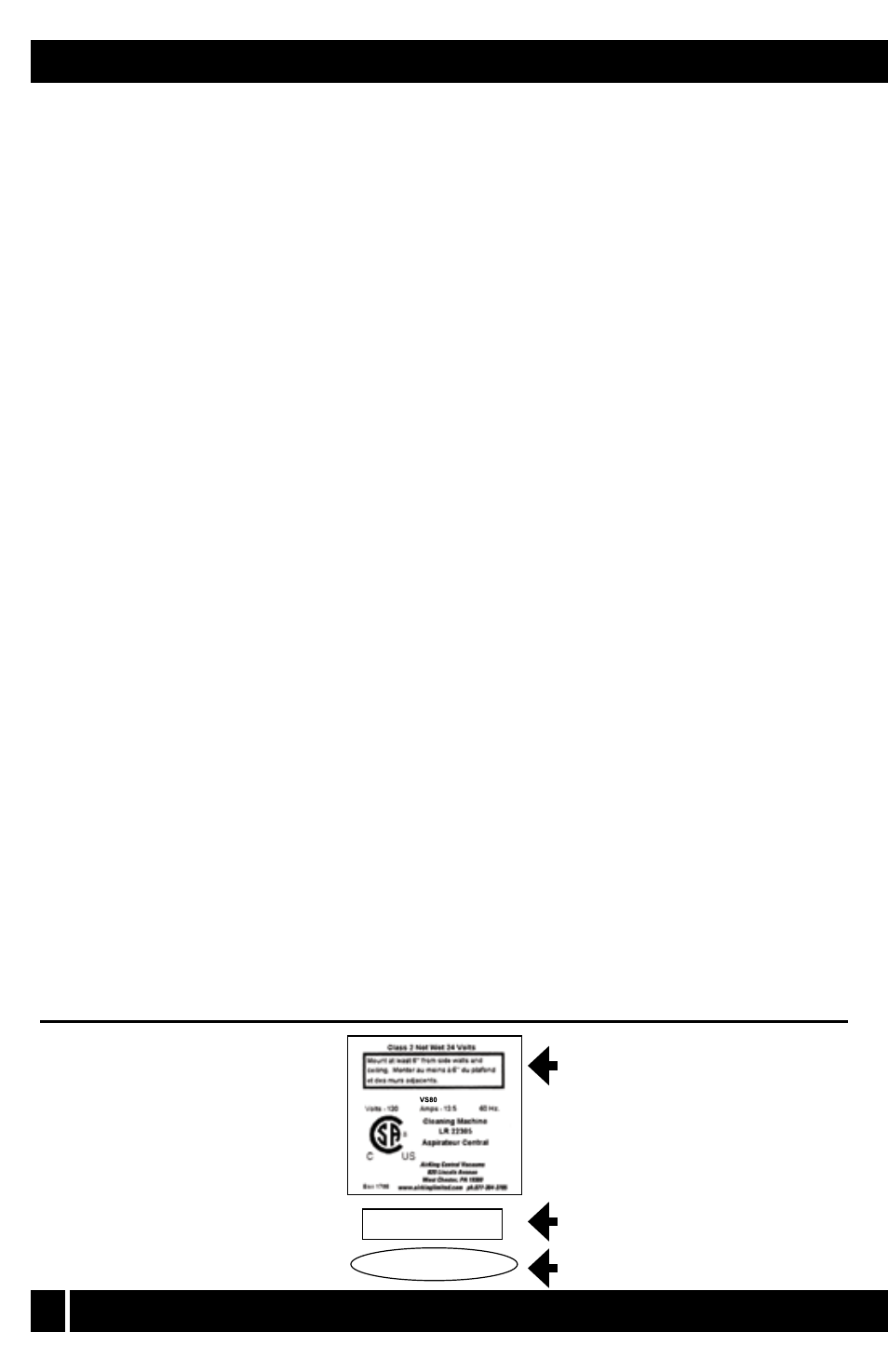

IMPOrtant

-

SErIaL NUMBEr LOCaTION fOr

CENTraL VaCUUM SYSTEM

Unit Label

(representative only - yours may differ)

date Code

(representative only - yours may differ)

Serial Number

(representative only - yours may differ)

XXXX

XXXXXXXXXXX

68

The serial number for your wall mounted

central vacuum system can be found

located under the unit model label (see

representative diagram below). The unit

model label will be found on the left or

right side of the unit near the top and

close to the wall.