Hydromax, Plumbing, Domestic water piping – Amtrol HYDROMAX HM-41L User Manual

Page 4: Boiler piping, Piping using zone valve

-4-

4. HYDROMAX

™

Plumbing

DOMESTIC WATER PIPING

1. Connect the cold water supply to the pipe labeled

COLD WATER.

2. Connect the HOT WATER piping to the domestic hot

water system.

3. When all domestic water piping is complete, open the cold water

supply and allow some water to enter the tank. Look and listen

for signs of leaks and repair as necessary before continuing.

Note: If installing on a city supply, a properly sized thermal expansion

tank is required and should be installed in accordance with the

product installation manual.

Note: If a water heater is installed in a closed water supply system,

such as one having a back-flow preventer in the cold water supply,

means shall be provided to control thermal expansion. Contact

the water supplier or local plumbing inspector on how to control

this situation.

Note: If an external electrical source is utilized, the appliance, when

installed,must be electrically grounded in accordance with local

codes or, in the absence of local codes, with the National Electrical

Code, ANSI/NFPA 70.

Note: The thermostat is adjusted to 120° F, when shipped from

the factory.

4. Install the blowdown tube on the T&P relief valve outlet.

Plumb to within 6 inches above a floor drain or as directed by

plumbing code.

Do not drill, puncture or otherwise

penetrate the steel outer tank shell.

Do not screw pipe hangers or other hardware into the

exterior of the tank.

BOILER PIPING

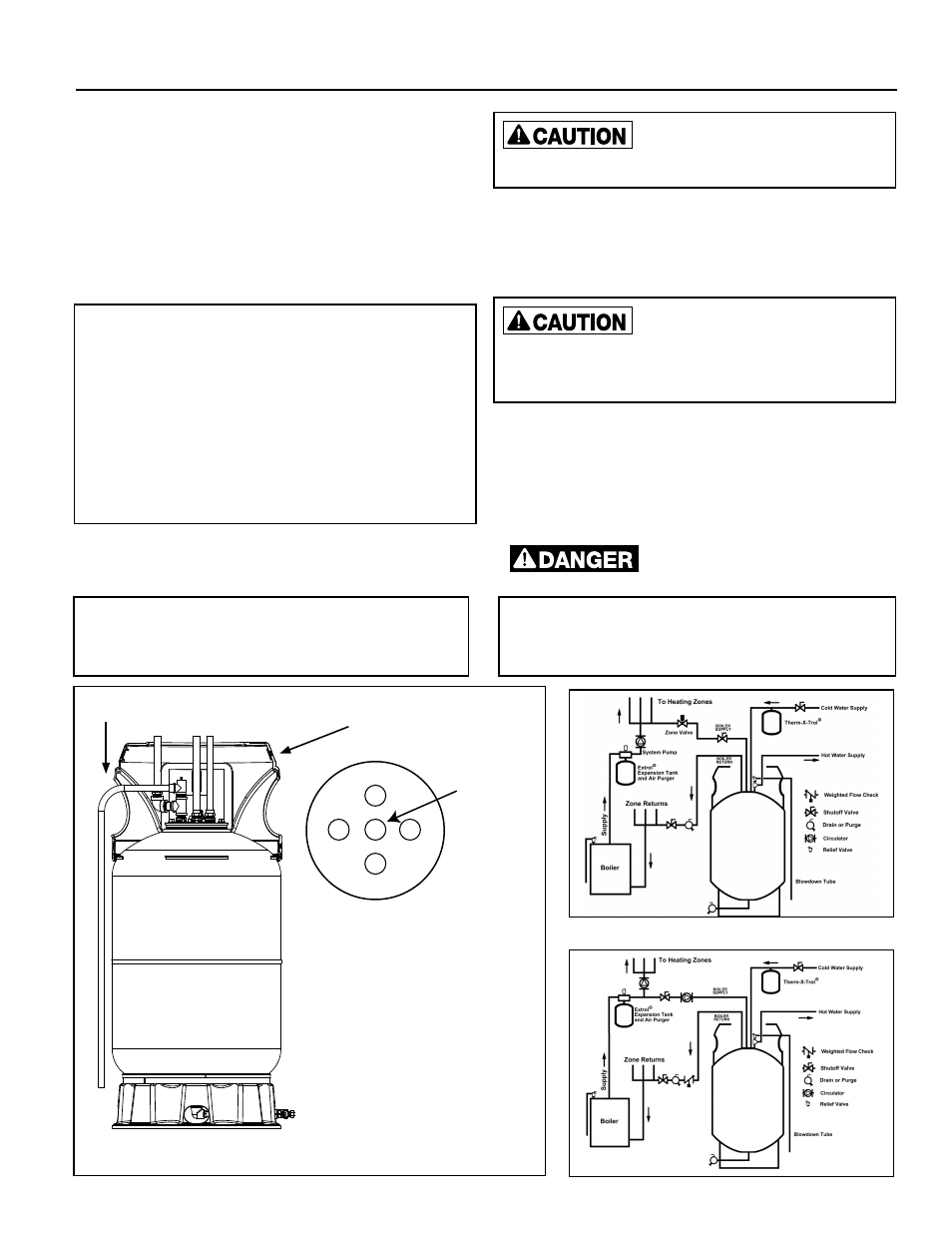

1. Plumb the circulator or zone valve on the BOILER

SUPPLY line.

2. Pipe the BOILER RETURN connection to the boiler return line.

Be sure the return line is NOT

plumbed to the suction side of any

heating circulators. This may require moving the heating

circulator off the boiler tapping on packaged boilers.

Failure to do so will result in overheating and tank

damage when the heating system is in operation.

3. Install a weighted flow check on the boiler return line. This is

not necessary on systems utilizing a zone valve to control the

water heater temperature.

4. After completing the boiler piping, slowly open the boiler fill

valve and pressurize the water heater loop. Check for leaks

and repair as necessary. Proceed to the appropriate wiring

section in this manual.

EXPLOSION HAZARD. Do not install to

a high pressure steam boiler (greater

than 15 psig). An explosion could occur.

LEFT SIDE . . . . . . . . . . . 1"

RIGHT SIDE. . . . . . . . . . 1"

TOP . . . . . . . . . . . . . . . . 9"

REAR . . . . . . . . . . . . . . . 1"

FLOOR. . . . . . . . . . . . . . 0"

FRONT. . . . . . . . . . . . . . 1"

Clearance From Combustible Surfaces

LEFT. . . . . . . . . . . . . . . 12"

RIGHT . . . . . . . . . . . . . 12"

FRONT. . . . . . . . . . . . . 30"

HEAD ROOM. . . . . . . 36"

REAR . . . . . . . . . . . . . . 1"

Recommended Clearance for Servicing

PIPING USING ZONE VALVE

REAR VIEW

(FOR CLARITY)

DRAIN

BLOWDOWN

TUBE

TOP VIEW

FROM FRONT

WIRING AND AQUASTAT

ON FRONT CAP HALF

BOILER RETURN

BOILER SUPPLY

TEMPERATURE

SENSOR WELL

HOT WATER

OUTLET

COLD WATER

SUPPLY