Troubleshooting and correction, 0 troubleshooting and correction – Nilfisk-ALTO Kew 30CA COMPACT I User Manual

Page 13

12

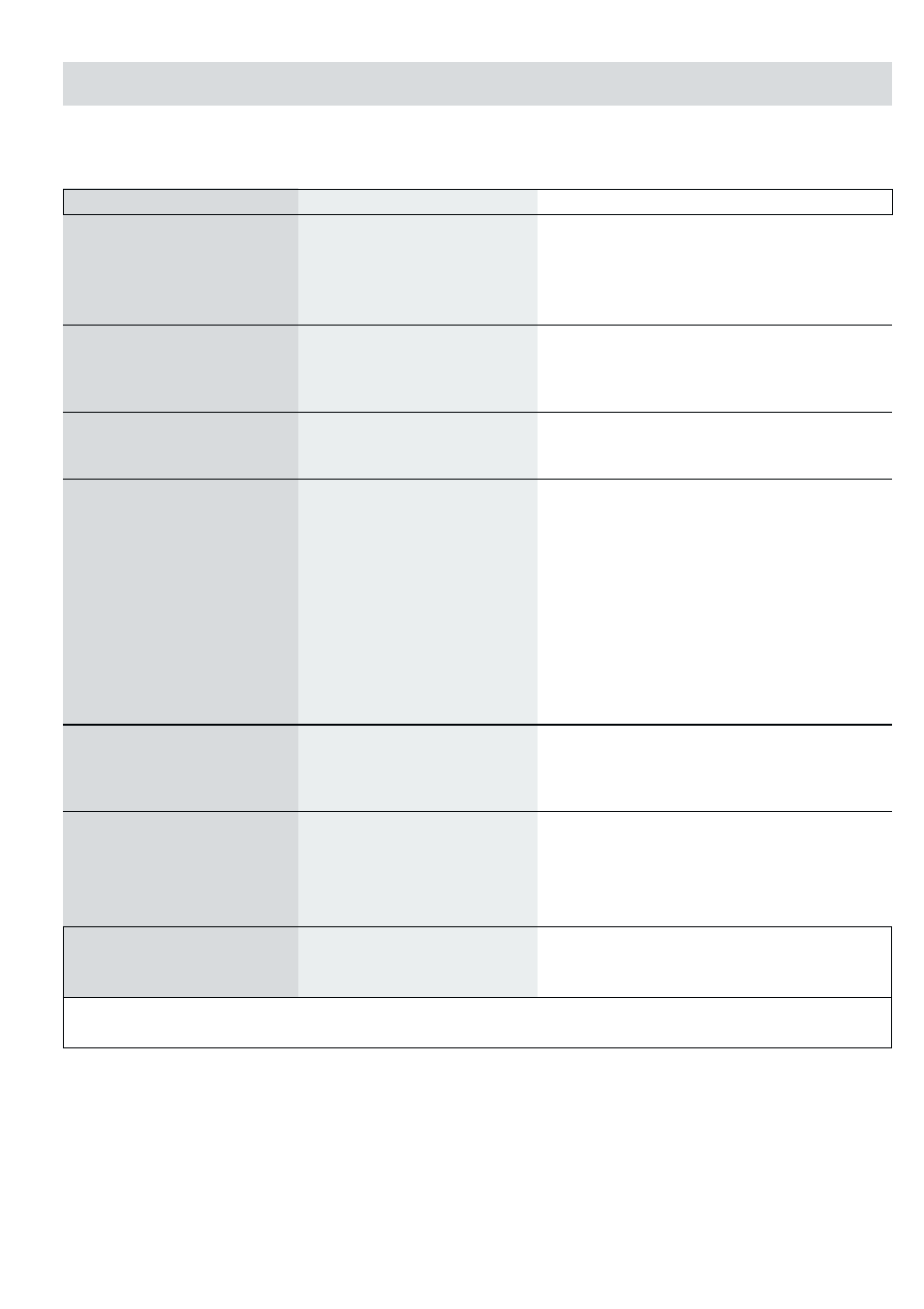

7.0 Troubleshooting and correction

You have chosen the best quality and therefore deserve the best service. To avoid unnecessary disap-

pointments, you should check the following before contacting the nearest ALTO service organisation.

Fault

Possible Cause

Remedies

Motor won't start

Plug not connected

Connect plug.

GFCI not set (if equipped)

Reset GFCI.

Defective outlet

Try another outlet.

Fuse/breaker blown

Change or reset the fuse/breaker. Switch off

any other devices. Try without extension cord.

Motor stops

Defective extension cord

Remove cord, reset breaker and try again.

Fuse/breaker blown

Switch off any other devices. Check that the

voltage is correct.

Overload release activated.

Turn start/stop knob off and on, again.

Fuse blows repeatedly

Wrong voltage and/or breaker

Change to a circuit with correct ampere and

voltage ratings.

Overload release activated

Check supply voltage and cord(s).

Pump pressure fluctuating

Air in the water hose and/

Allow the machine to run with open spray lance

or pump

adjusted to low pressure until the flow is steady.

Inadequate water supply

Check that the water supply is adequate for the

machine. Avoid long, thin hoses (min. i.d. ½").

Inlet water screen clogged

Clean the screen (see sec. 6.2)

Hoses kinked

Straighten the hoses.

High pressure hoses too long

Detach high pressure extension hoses and retry

(extension hoses max. 33 ft).

(in suction mode)

Read section 5.0.

Suction height too high, water

Use cooler water, reduce suction distance and

too hot, or air leak in supply

check for poor hose connections.

hose

Pressure low but steady

High pressure nozzle worn

Replace the nozzle.

Note:

Some accessories normally

Dirt in by-pass valve

Activate and release the spray handle 5 times,

operate at a lower pressure

quickly.

Motor runs but no working

Pump/hoses or accessories

Let pump/hoses or accessories thaw.

pressure

frozen

No water supply

Connect or turn on the water.

Inlet water screen clogged

Clean the screen (see Sec. 6.2)

Nozzle clogged

Clear the nozzle (see Sec. 6.1)

*) Overload release

Wrong voltage

See section 2.2

activated

Extension cord too long

Remove the cord or use larger cord.

Nozzle partly obstructed

Clear the nozzle (see Sec. 6.1)

Wait until the motor has cooled. (The machine can be restarted by turning te start/stop knob to 0 and back to I).

Should you experience malfunctions other than those mentioned above, please contact ALTO Service for

assistance.