2 installation guidelines, Wiring, Programming example – Campbell Scientific CS445 Liquid Level Sensor User Manual

Page 7

CS445 Liquid Level Sensor

3

tubes should be inspected regularly (i.e., every two months) and historical

information will help to baseline desiccant replacement requirements for a

given application/climate.

Absolute pressure (Non-Vented) units do not require a desiccant chamber. If

the cable incorporates a vent tube, the vent tube is heat sealed at both ends

prior to shipment and must remain sealed.

Remember that although the CS445 is designed to be a rugged and reliable

device for field use, it is also a highly precise scientific instrument and should

be handled as such. There are no user serviceable parts and any attempt to

disassemble the device will void the warranty.

3.2 Installation Guidelines

The CS445 is designed for water level measurement. Typical applications

include agricultural water level/flow, water wells, lakes, streams and tanks. If

the device is to be installed in a liquid other then water or in contaminated

water, check the compatibility of the wetted materials.

The Transducer may be installed in any position but it is calibrated and tested

in the vertical orientation, as it would normally be suspended.

Never suspend the transducer from the connections at the top end of the cable.

When suspending the device, in a well for example, a proper strain relief

should be attached around the cable jacket and properly secured at the well

head.

Although the cable jacket is made from a thick, tough polyurethane formation,

care should be taken to avoid cable damage. Further, sharp bends or excessive

pinching of the cable can cause damage and may pinch off the vent tube

causing measurement errors in the case of gauge pressure (Vented) devices.

Do not drop the instrument or allow it to “free fall” down a well as this may

damage the device.

Never attempt to disassemble the transducer as this will void the warranty.

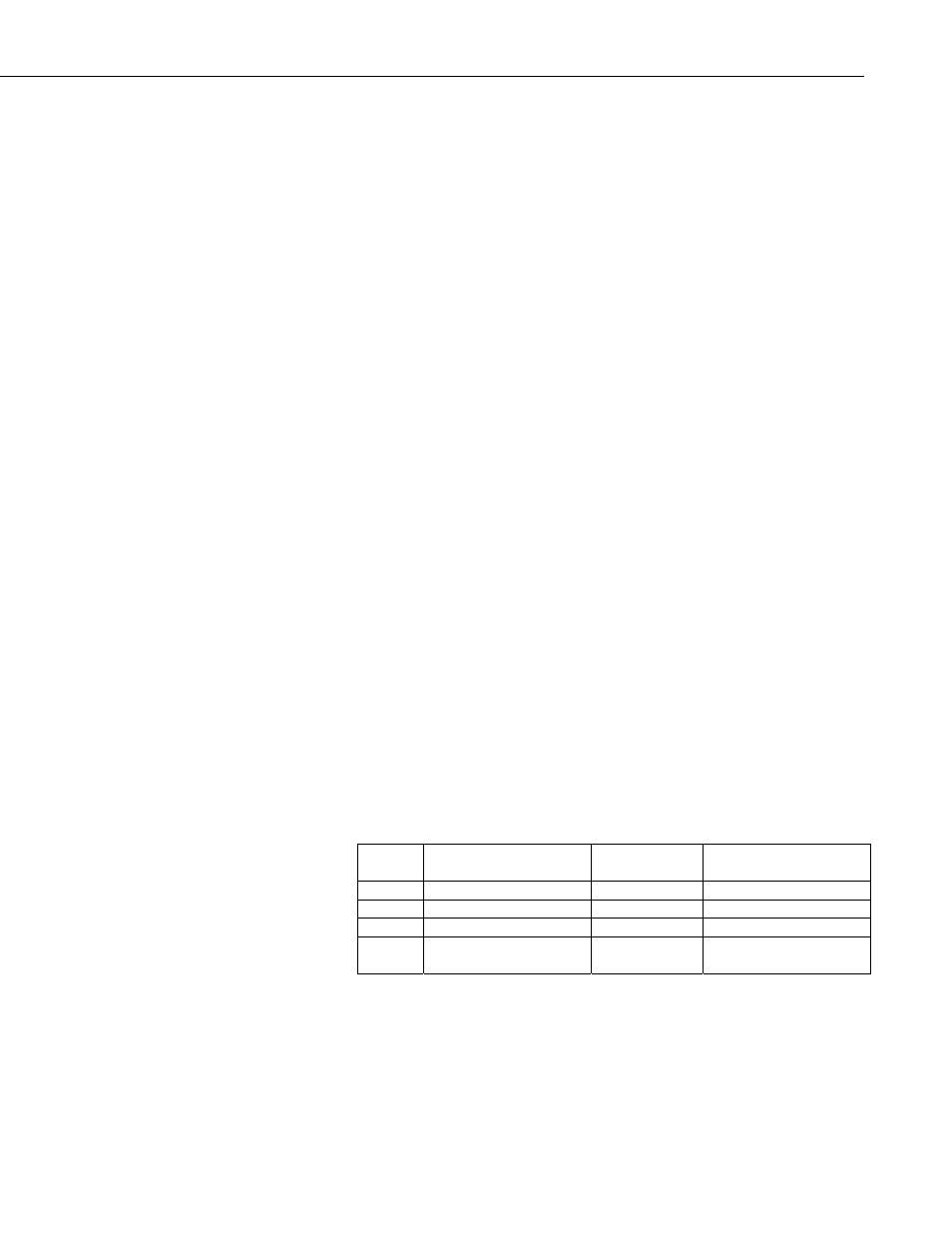

4. Wiring

Color

Function

CR200 Series

CR23X, CR10(X),

CR510, CR500

Red

+ Power. 8 to 24 VDC

Battery +

12V

Black

Ground

G

G

Brown

SDI-12 Data Line

C1/SDI-12

Control Port 1-8

Clear

Shield. Not connected

to transducer body

G

G

5. Programming Example

The CS445 uses an SDI-12 compatible hardware interface and supports a

subset of the SDI-12 commands. The most commonly used command is the

aM! command, issued by the datalogger. Here, ‘a’ represents the sensor

address (0 – 9). The communication sequence begins with the datalogger