Greenheck Model G User Manual

Page 7

7

Downblast Centrifugal Roof Exhaust Fans

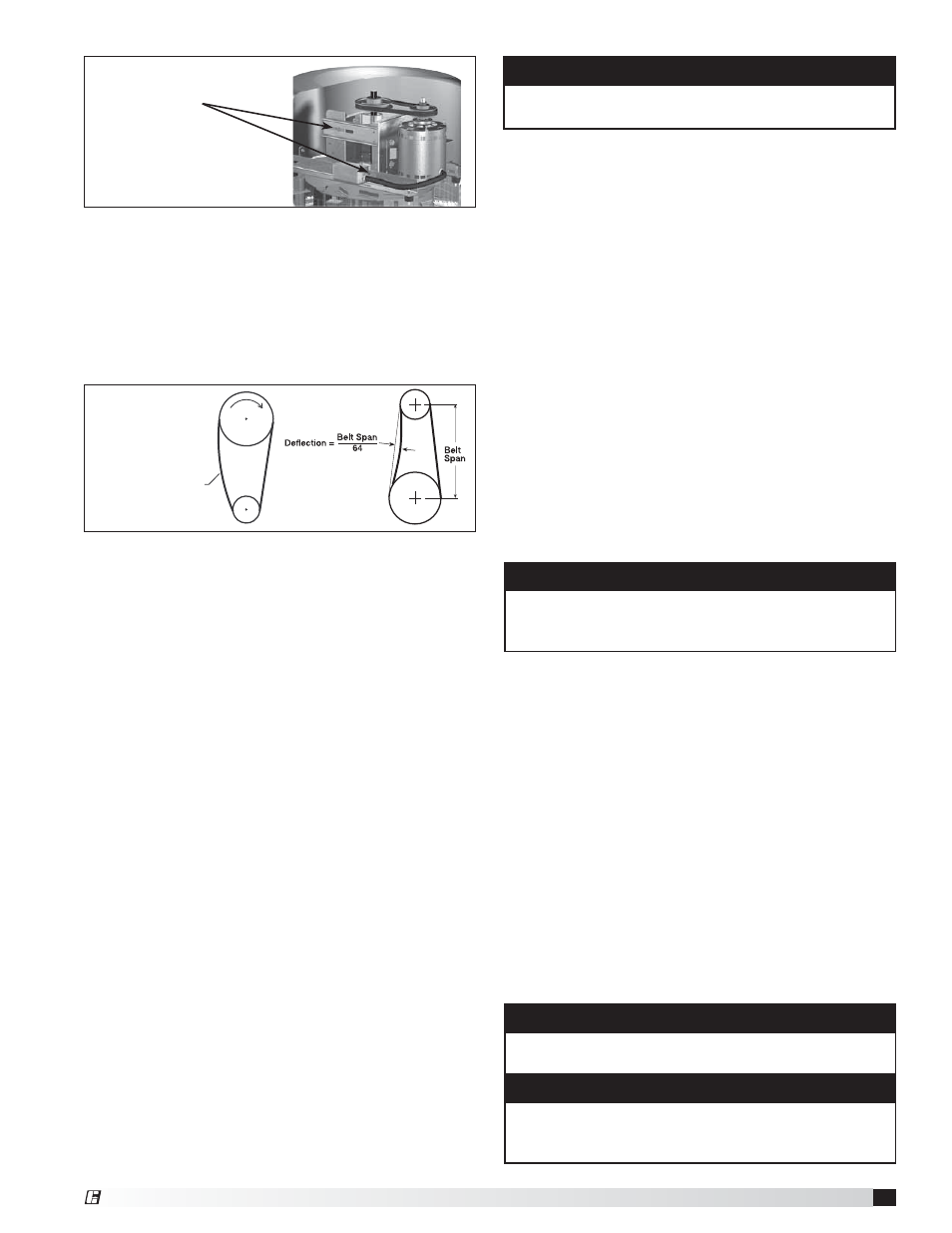

11. Belt tension can be adjusted by loosening four

fasteners on the drive frame, see Figure 11. The

motor plate slides on the slotted adjusting arms and

drive frame angles in the same manner.

12a. Sizes 071-161: Belts should be tensioned just

enough to prevent slippage at full load.

Note: Belts should have a slight bow on the slack

side while running at full load (see Figure 12a).

12b. Sizes 180-540: Belt tension should be adjusted to

allow 1/64 in. (0.397 mm) of deflection per inch of

belt span. For example, a 15 in. (381 mm) belt span

should have 15/64 in. (0.234 mm) (or about 1/4 in.

(6 mm)) of deflection with moderate thumb pressure

at mid-point between pulleys (see Figure 12b).

13. The adjustable motor pulley is factory set for the

RPM specified. Speed can be increased by closing

or decreased by opening the adjustable motor pulley.

14. Any increase in speed represents a substantial

increase in the horsepower required by the unit.

15. Motor amperage should always be checked to avoid

serious damage to the motor when speed is varied.

Operation: G / GB

1. Before starting up or operating fan, check all

fasteners for tightness. In particular, check the

setscrews in wheel hub.

2. While in the OFF position or before connecting the

fan to power, turn the fan wheel by hand to be sure

it is not striking the venturi or any obstacle.

3. Start the fan and shut it off immediately to check

rotation of the wheel with directional arrow in the

motor compartment.

4. When the fan is started, observe the operation and

check for any unusual noises.

5. With the system in full operation and all ductwork

attached, measure current input to the motor and

compare with the nameplate rating to determine if

the motor is operating under safe load conditions.

6. Keep inlets and approaches to fan clean and free

from obstruction.

IMPORTANT

Adjust (tighten) belt tension after the first 24-48 hours

of operation.

Inspection

Inspection of the fan should be conducted at the

first 30 minute and 24 hour intervals of satisfactory

operation.

30 Minute Interval

Inspect bolts, setscrews and motor mounting bolts.

Adjust and tighten as necessary.

24 Hour Interval

Check all internal components. On GB unit only, inspect

belt alignment and tension. Adjust and tighten as

necessary.

Maintenance: G / GB

Installation and maintenance are to be performed only

by qualified personnel who are familiar with local codes

and regulations and who are experienced with this type

of equipment.

Motor maintenance is generally limited to cleaning

and lubrication (where applicable). Cleaning should be

limited to exterior surfaces only. Removing dust buildup

on motor housing ensures proper motor cooling.

WARNING

Always disconnect, lock and tag power source before

servicing. Failure to disconnect power source can

result in fire, shock or serious injury.

Greasing of motors is only intended when fittings are

provided. Many fractional horsepower motors are

permanently lubricated and should not be lubricated

after installation. Motors supplied with grease fittings

should be greased in accordance with manufacturers’

recommendations. Where motor temperatures do not

exceed 104ºF (40ºC), the grease should be replaced

after 2,000 hours of running time as a general rule.

Wheels require very little attention when moving clean

air. Occasionally, oil and dust may accumulate causing

imbalance. When this occurs, the wheel and housing

should be cleaned to ensure smooth and safe operation.

All fasteners should be checked for tightness each time

maintenance checks are performed prior to restarting

unit.

A proper maintenance program will help these units

deliver years of dependable service.

CAUTION

Uneven cleaning of the wheel will produce an out of

balance condition that will cause vibration in the fan.

WARNING

This unit should be made non-functional when

cleaning the wheel or housing (fuses removed,

disconnect locked off).

Slack

Side

Deflection

Figure 12a

Figure 12b

Fasteners

(4) four fasteners*

*Identical fasteners on

opposing side must also

be loosened.

Figure 11

®