Operation, Warning – Hot Max Torches 135WFG User Manual

Page 14

KDAR Company

13

Operation

Wire Feeding

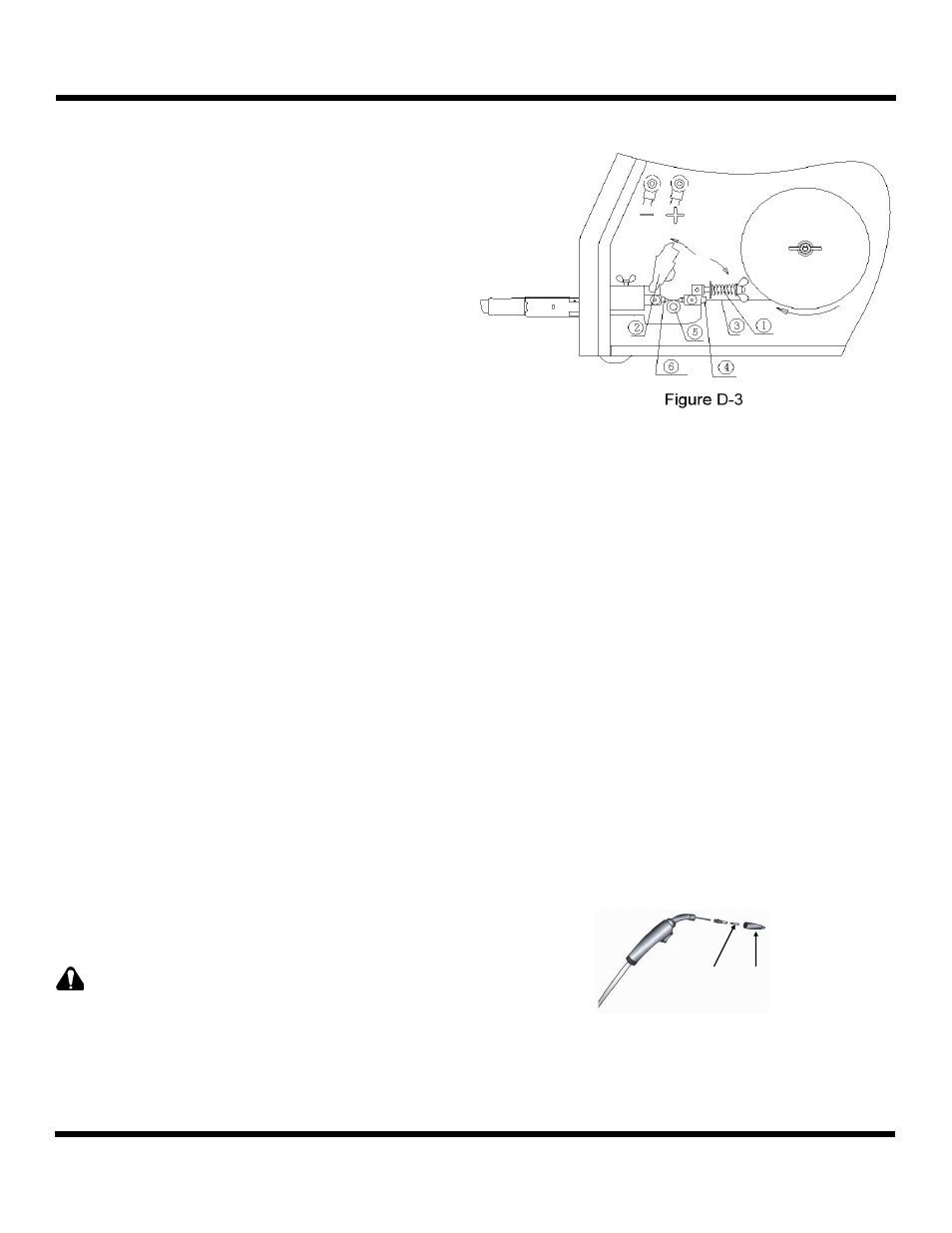

1. Release the spring loaded tension arm (1) by flip-

ping it to the right and down.

2. Lift the idle arm (2).

3. Make sure the grove size on the drive roll (5) is in

the feeding position that matches the wire size be-

ing used. Refer to the Suggested Settings for

Welding chart at the back of this manual or on the

inside of the welder compartment door.

4. Detach the end of the wire from the spool and clip

a small amount of wire to get a good straight start.

Note: In order to prevent the spool from un-

winding; it is important to keep tension on the wire

until after the idle arm and tension arm are back in

place.

5. Thread the wire through the inlet tube (4), over the

drive roll (5) and into the outlet guide tube (6).

6. Close the idle arm (2).

7. Move the spring loaded tension arm (1) into posi-

tion.

8. If required, rotate the wire spool counter clockwise

to take up any slack in the wire.

9. If feeding problem occur because the wire is ex-

cessively flattened, turn the wing nut on the spring

loaded tension arm (1) counter clockwise to reduce

the pressure. If the drive roll (5) is slipping while

feeding the wire; turn the wing nut clockwise to

create more tension on the wire.

When feeding the wire, the drive roll, the connector

block and gun contact tip are electrically charged

relative to work and ground and remain charged

for several seconds after the gun trigger is released.

Warning

8

7

Figure 13

10. Remove nozzle (7) and contact tip (8) from

end of gun.

11. Turn on the Hot Max 135WFG.

12. With the gun cable assembly straight; press the

trigger switch. The welding wire will feed

through the cable and gun. Release the trigger

when the wire has fed approximately 2 inches

past the end of the gun.

13. Turn off the Hot Max WFG.

14. Replace the contact tip (8) and nozzle (7)

15. Cut wire off approximately 3/8” from the end

of the contact tip. The Hot Max 135WFG is

ready for welding.