Drum capacity (feet) – Bloom Manufacturing LS12H Series User Manual

Page 7

• To familiarize yourself with the winch, run it for a few minutes to understand the controls and the “feel” of the winch.

• Pay particular attention to the controls and how they operate. Make sure you understand which way the winch will

Section 6

Winch Operation

rotate when the control lever is moved.

• Always make sure that all people are clear of the load and of the cable area before beginning a winching operation.

• Ensure that proper protective wear is worn while operating winch.

• A broken cable can fly in any direction.

• Do not attempt to defeat the relief valve

Winch lifting application:

Direct Drive:

(1) Att h i h bl t l d

Do not attempt to defeat the relief valve.

• If you have any doubts about the capability of the winch to lift or move a load, either put a “snatch block” in the line or

get a bigger piece of equipment.

(1) Attach winch cable to load.

(2) Make sure no one is in the immediate area of the load or of the cable

(3) Begin winching the load slowly, watching carefully to ensure that the load is moving normally.

(4) When the load is positioned where you want it, stop the winch.

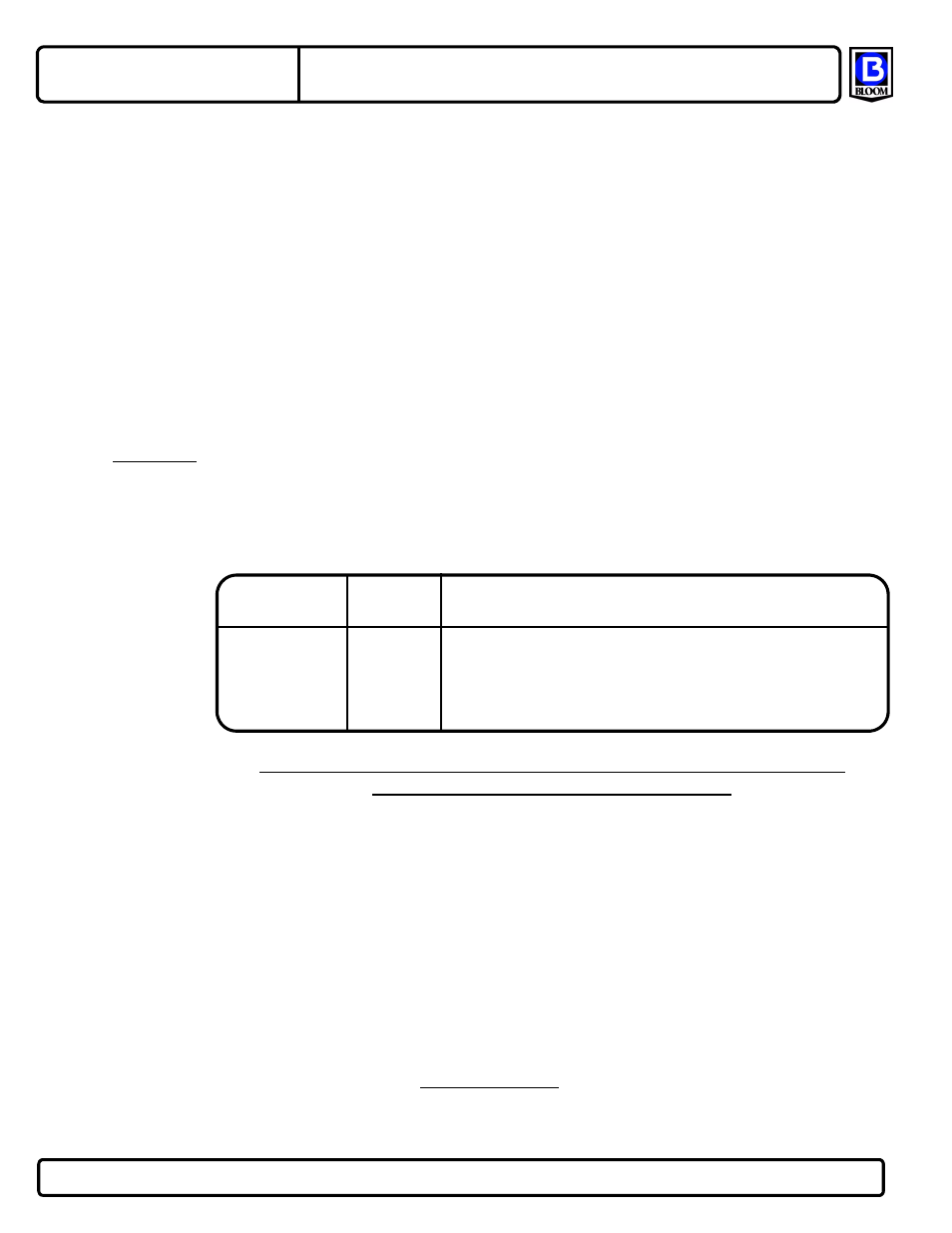

Drum

Cable Diameter (inches)

Designation

3/16

1/4

5/16

3/8

7/16

1/2

9/16

5/8

Winch Series

Consult your local cable supplier for recommendations on the best type of cable

DRUM CAPACITY

(FEET)

S8

-----

260

160

105

75

55

-----

-----

L8

-----

390

240

160

110

80

-----

-----

XL10 -----

840 550 340 250 170 -----

------

S

-----

120

70

45

30

25

-----

-----

L

-----

175

105

65

45

30

-----

-----

LS8H, LS10H,

LS11H, LS12H

Consult your local cable supplier for recommendations on the best type of cable

and hardware to use in your specific application.

(a) Cable Considerations:

As the number of layers of cable on a winch increases, the rated lifting capacity of the winch goes down. If you are

operating at near the top of the drum flanges, the effective rating of the winch is about half of what it is on the first layer.

You should, therefore, only keep as much cable on the winch as you need for your job.

Never use larger or smaller cable on your winch than is recommended for it. The use of larger cable will not allow you to

pull larger loads and may, in fact, break easier than the proper size cable. The use of smaller cable may overheat the

winch due to the increased running time with more cable.

(b) The Importance of a Proper Fleet Angle:

Maintaining the proper fleet angle is important to the success of your winching operation, the life of your winch and the

life of the cable you are using. The fleet angle can best be described by the following diagram:

The fleet angle should be kept as small as possible to ensure proper spooling and to maximize cable and winch life To

For Best Results, Only Use Bloom Replacement Parts 800-394-1139

The fleet angle should be kept as small as possible to ensure proper spooling and to maximize cable and winch life. To

promote even cable spooling, keep the fleet angle below three degrees. Never pull directly against the flange of the

winch cable drum as this may cause the cable or the winch to break. Adherence to these instructions will ensure better

spooling.

7