Table 1 - inspection chart – OZ Lifting Products HD OZ Economy Lever Hoist OM User Manual

Page 10

pg.10

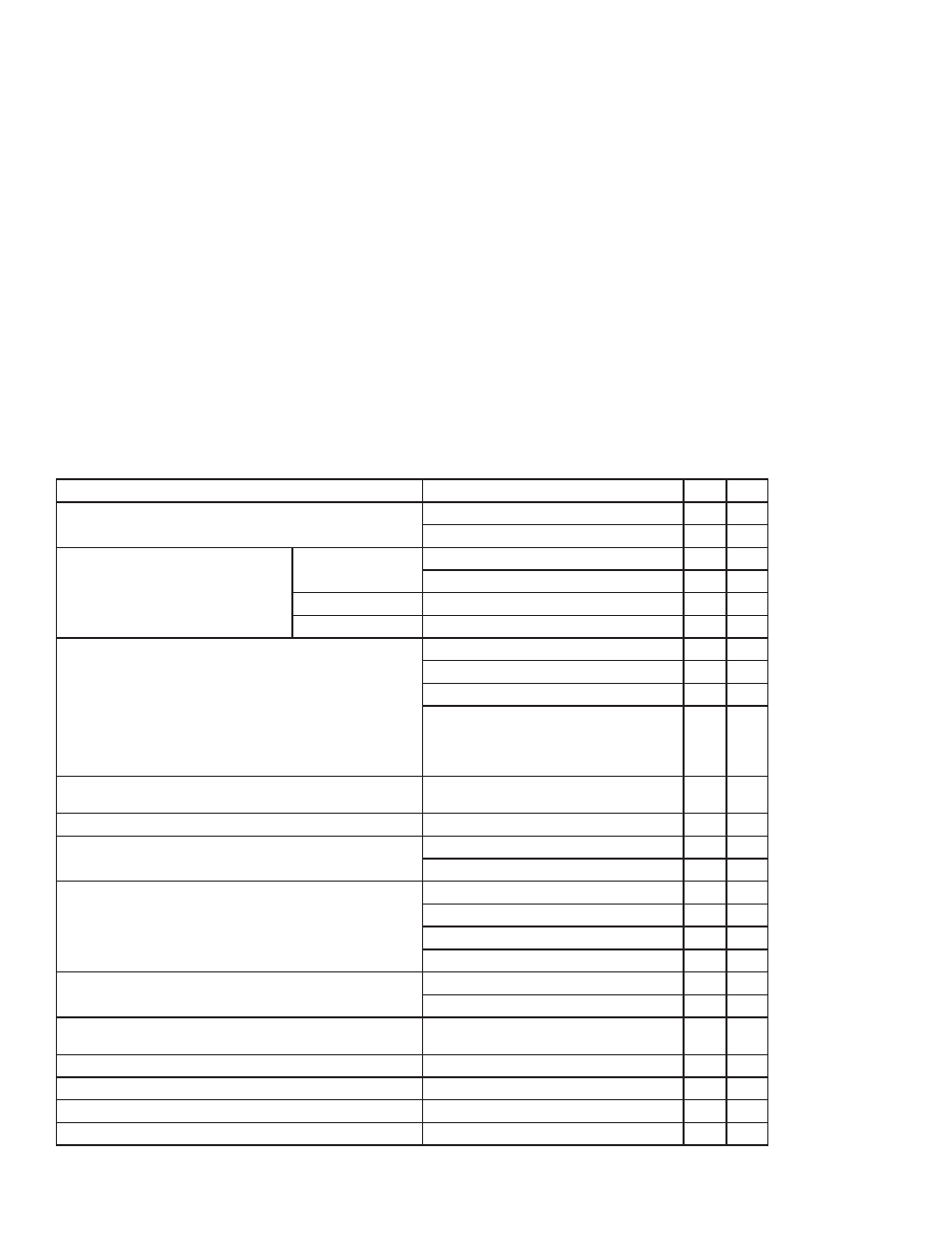

TABLE 1 - INSPECTION CHART

In chart,

F indicates Frequent Inspection, P indicates Periodic Inspection

LOCATION

CHECK FOR

F

P

Braking mechanism

Slipping under load

•

Hard to release

•

Brake parts:

Brake Discs

Glazing

•

Oil contamination

•

Pawl: Ratchet

Excessive wear

•

Pawl: Spring

Corrosion: stretch

•

Hook

Chemical damage

•

Operation

•

Deformation

•

Cracks (dye penetrant, magnetic

particle, or other suitable detection

method)

•

Hook retaining members Not tight or secure

(Pins, Bolts, Nuts)

Not tight, secure or damaged

•

Hook Latch

Damaged; does not close

•

Suspension Members (Sheaves, Hand-wheels, Chain attachments,

Suspension bolts or pins)

Excessive wear

•

Cracks

•

•

Gears

Distortion

•

Broken or worn teeth

•

Cracks

•

Inadequate lubrication

•

Load Block: Suspension housing

Distortion

•

•

Crack

•

•

Trolley: Supporting structure

Possible inability to continue

supporting loads or damaged

•

Bolts, Nuts, Rivets

Not tight or secure

•

WARNING Labels

Removed or not legible

•

Hoist Lever

Bent, cracked

•

Proper operation

Unusual sounds

•

Frequent Inspections

The operator or other designated person performs frequent inspections by doing a visual examination and

by listening for unusual sounds while product is operating. Frequent inspections are usually performed on

the following schedule:

Normal Service- Monthly inspections

Heavy Service- Weekly to monthly inspections

Severe Service- Daily or before each use to weekly inspections

Periodic Inspections

A designated person performs periodic inspections, which are more detailed inspections, by doing visual

examinations of external and internal conditions. These inspections are done on the following schedule:

Normal Service- Yearly inspection

Heavy Service- Semi-annually inspections

Severe Service- Quarterly inspections