E-series machine screw jack – Power Jacks E-Series - Machine User Manual

Page 3

www.powerjacks.com

E-Series Machine Screw Jack

3

be treated as an emergency device only and must not be allowed to come into contact with the worm gears

during normal working cycles otherwise serious damage will result to worm gears and bearings.

1.18 The maximum worm shaft speed for these screw jacks should not exceed 500 R.P.M. for heavy loads. Refer

to Power Jacks Limited for higher worm shaft speeds for lighter loads. the input power should not exceed

the power rating shown in the catalogues screw jack performance tables.

1.19 The lead screws should not be permitted to accumulate dust and grit on the threads. If possible, lead screws

should be returned to the closed position (retracted) when not in use.

1.20 If equipped with bellows boot the boot must not be compressed bellow its minimum height (consult Power

Jacks product literature or engineers).

2-Lubrication Of The Screw Jack

2.1 The screw jacks are shipped packed with grease (unless otherwise called for) which should be sufficient for

one month of normal operation.

2.2 IMPORTANT NOTE – Lubricant suitability is dependent on duty cycle and ambient temperature. However in

general recommended lubricants are suitable for operation in an ambient temperature of -10ºC to +50ºC. If

in doubt consult with Power Jacks prior to installation and operation.

2.3 The maintenance engineer should establish a lubrication programme based on the screw jack’s duty and

use.

2.4 The lead screw requires a light grease film to be applied at Installation. The lead screw should not be over

greased.

2.5 Note excessive grease should be avoided.

2.6 It is recommended that the screw jack be fitted with bellows or covers to protect the exposed screw from

contamination from dirt and debris.

2.7 If the screw jack or its system is fitted with a brake ensure that under no circumstances lubricant gets into

the brake as this can cause brake failure due to loss of friction.

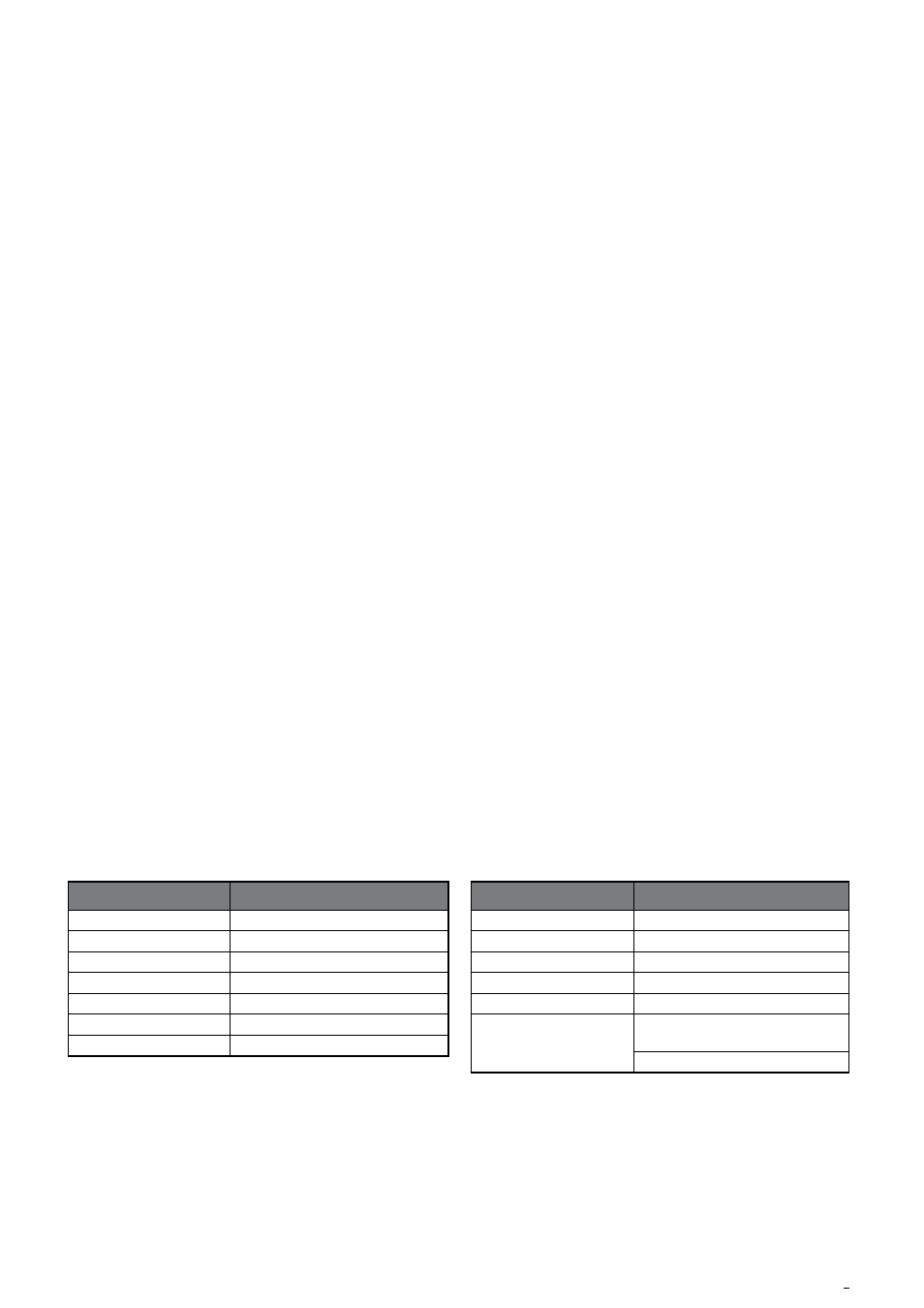

3-Recommended Lubricants

Manufacturer

Lubricant

Castrol

Spheerol EPL2

Esso

Beacon EP2

Gulf

Gulfcrown EP2

Mobiloil

Mobilux EP2

Power Petroleum

BP Energrease LC2

Regent

Texaco EP2

Shell

Gadus S2V220AC2 (Alvania WR2)

Table 1 - Normal Operation

Manufacturer

Lubricant

Castrol

Spheerol LMM2

Esso

Beacon EP2 Moly

Mobiloil

Mobilgrease XHP222 Special

Power Petroleum

BP Energrease L2 1M

Regent

Molytex 2

Shell

Shell Greases 5826

(Overseas)

Shell Alvania HDX2

Table 2 - Arduous Operation