Troubleshooting – Haws 8309WC User Manual

Page 3

12/09

Model 8309WC

Page 3 of 5

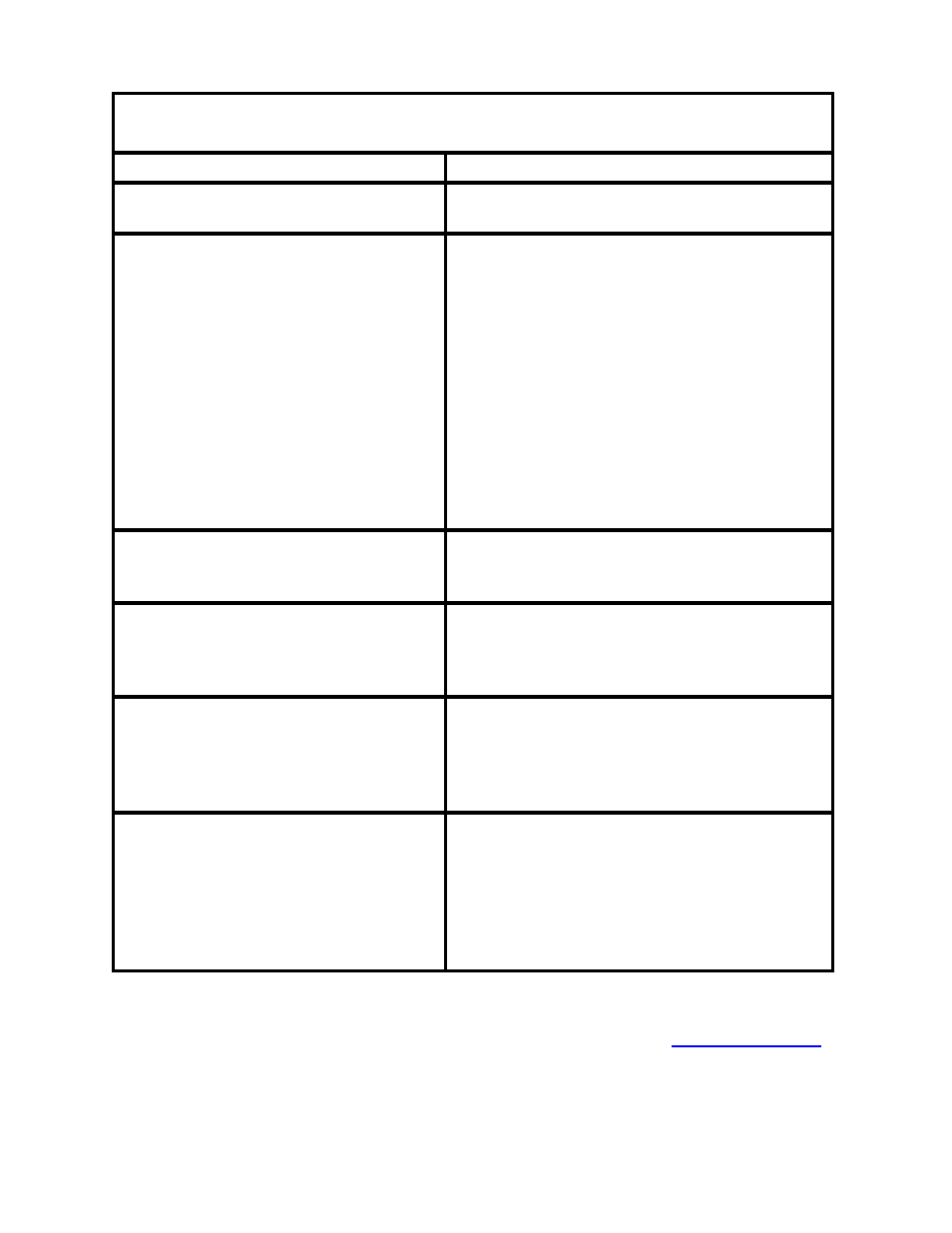

TROUBLESHOOTING

PROBLEM

REPAIR CHECKLIST

1. No flow.

1.

Check the main shut-off valve.

2. Insufficient water flow, shower

and eyewash.

2.

Verify minimum 30 psi (2 ATM) flowing

supply line pressure.

3. Insufficient water flow on

eyewash, however, shower is

sufficient.

3a. Verify minimum 30 psi (2 ATM) flowing

supply line pressure.

b. Probable clogging of flow control due to

inadequate line flushing. Unscrew

eye/face wash head and remove the

four screws to disassemble the head.

Clean flow control and reassemble

head. See SP65 Installation Drawing

for details.

c. Remove cap located on L – Strainer

using a 3/8” allen wrench to access and

clean filter screen.

4. Eyewash or face wash streams

do not meet desired eye level or

are not balanced.

4a. Possible blocked flow control see

above solution. (Possible non-leveled

eyewash assembly.)

5. Insufficient water flow at the

showerhead, however, eyewash

is sufficient.

5a.

Probable clogging of flow control inside

shower head. Unscrew shower head

off of elbow and clean rubber flow

control.

6. Water does not drain properly.

6a. Check your drain system for debris.

Check the main waste line of your

building to see if it does handle the

capacity required for the entire

drainage system.

7. Water leak between joints or

fittings.

7a. Tighten loose connections. If leak

persists, the application of hot water

will sometimes reseat improperly

applied joint compound. After 30

minutes wait and retest, a persistent

leak will necessitate reassembly and

additional sealant.

For more information on Haws Products, please see our website:

www.hawsco.com

© 2009 Haws

®

Corporation – All Rights Reserved

HAWS

®

and other trademarks used

in these materials are the exclusive property of Haws Corporation.