High altitude installations – State SHE50 100 User Manual

Page 15

15

The temperature-pressure relief valve must be manually

operated at least once a year , see Figure 28. Caution should be

taken to ensure that (1) no one is in front of or around the outlet

of the temperature-pressure relief valve discharge line, and (2)

the water manually discharged will not cause any bodily injury

or property damage because the water may be extremely hot.

If after manually operating the valve, it fails to completely reset

and continues to release water, immediately close the cold water

inlet to the water heater, follow the draining instructions, and

replace the temperature-pressure relief valve with a new one.

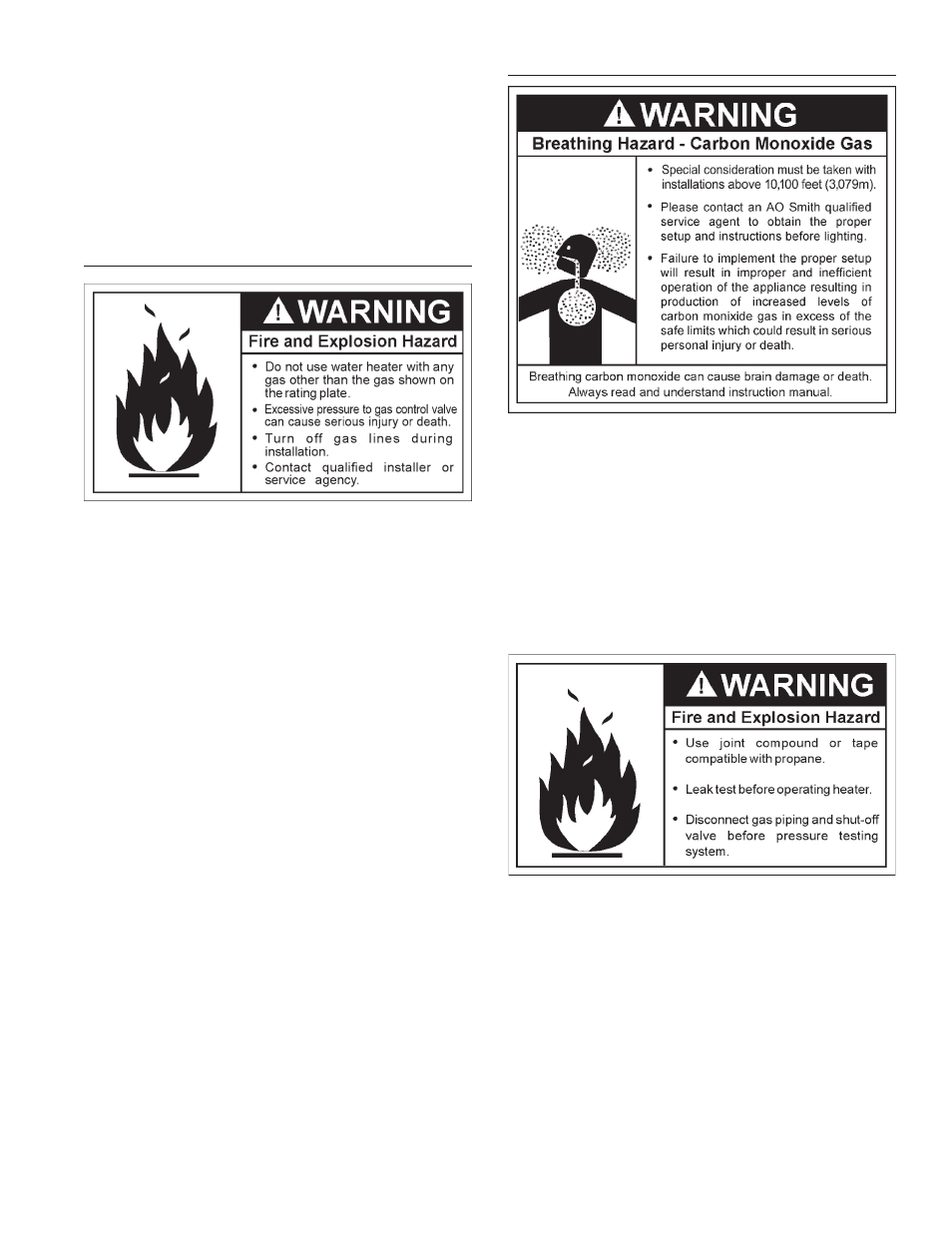

Gas pIpInG

Make sure gas supplied is same type listed on model rating plate. The

inlet gas pressure must not exceed 14 inch water column (3.5 kPa)

for natural and propane gas (L.P.). The minimum inlet gas pressure

shown on rating plate is that which will permit firing at rated input.

All gas piping must comply with local codes and ordinances or with the

National Fuel Gas Code (ANSI Z223.1/ NFPA-54) or the Natural

Gas and Propane Installation Code (CAN/CSA B149.1) whichever

applies. Copper or brass tubing and fittings (except tin lined copper

tubing) shall not be used.

If the gas control valve is subjected to pressures exceeding 1/2 psi

(3.5 kPa), the damage to the gas control valve could result in a fire

or explosion from leaking gas.

If the main gas line Shut-off serving all gas appliances is used, also

turn “off” the gas at each appliance. Leave all gas appliances shut

“off” until the water heater installation is complete.

A gas line of sufficient size must be run to the water heater.

Consult the current edition of National Fuel Gas Code

(ANSI Z223.1/NFPA 54) or the Natural Gas and Propane Installation

Code (CAN/CSA B149.1) and your gas supplier concerning pipe

size.

There must be:

• A readily accessible manual shut off valve in the gas supply

line serving the water heater, and

• A drip leg (sediment trap) ahead of the gas control valve to help

prevent dirt and foreign materials from entering the gas control

valve.

• A flexible gas connector or a ground joint union between the

shut off valve and control valve to permit servicing of the

unit.

Be sure to check all the gas piping for leaks before lighting the

water heater. Use a soapy water solution, not a match or open

flame. Rinse off soapy solution and wipe dry.

hIGh altItude InstallatIons

Rated inputs are suitable up to 10,100 feet (3,079m) elevation. Consult

the factory for installation at altitudes over 10,100 feet (3,079m).

WARNING: THIS HIGH EFFICIENCY WATER HEATER IS CERTIFIED

FOR USE WITHOUT MODIFICATION FOR AN ALTITUDE OF 10,100

FEET (3,079 METERS). INSTALLATIONS ABOVE THESE ALTITUDES

MAY REQUIRE REPLACEMENT OF BURNER ORIFICE. CALL THE

TECHNICAL CENTER AT (800) 527-1953 FOR REQUIREMENTS.

Some gas utility companies derate their gas for altitude, making

it unnecessary to install high altitude orifices. Call the local gas or

utility company to verify BTU content.

Due to the input ration reduction at high altitudes, the output rating

of the appliance is also reduced and should be compensated for in

the sizing of the equipment for applications.

Use pipe joint compound or teflon tape marked as being resistant

to the action of petroleum [Propane (L.P.)] gases.

The appliance and its gas connection must be leak tested before

placing the appliance in operation.

The appliance and its individual Shut-off valve shall be disconnected

from the gas supply piping system during any pressure testing of

that system at test pressures in excess of 1/2 pound per square inch

(3.5 kPa). It shall be isolated from the gas supply piping system

by closing its individual manual Shut-off valve during any pressure

testing of the gas supply piping system at test pressures equal to

or less than 1/2 pound per square inch (3.5 kPa).

IMportant: MaKe sure the Gas lIne Is pIped In wIth

hard pIpe. avoId fleX lIne constructIon for Gas due

to possIBle Gas flow proBleMs.