State SDV 75 70 NE/PE User Manual

Page 9

9

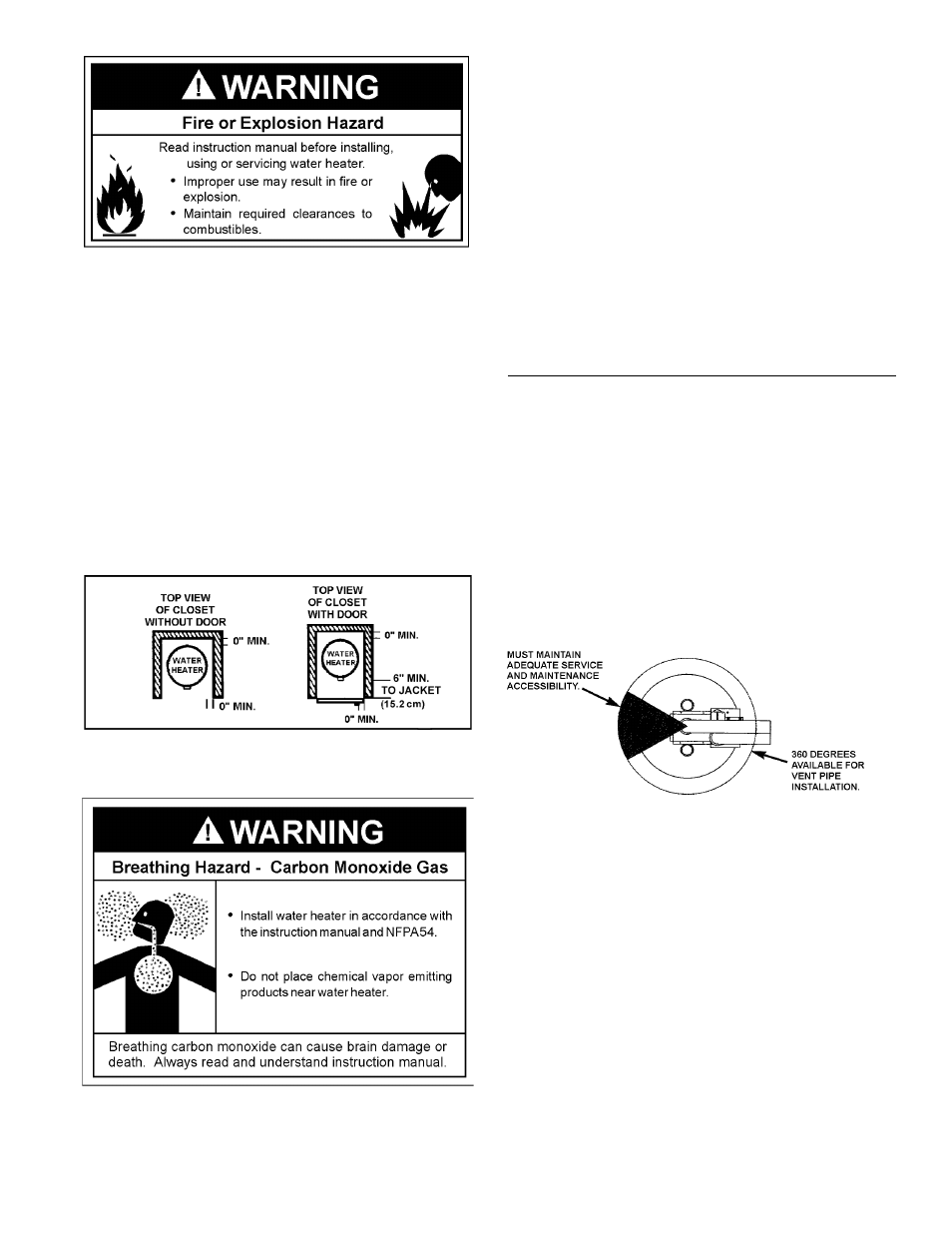

Minimum clearances between the water heater and combustible

construction are 0 inch at the sides and rear, 6” (15.2 cm) from the

front of the jacket, and 12” (30.5 cm) from the top (standard clearance).

If clearances stated on the heater differ from standard clearances,

install water heater according to clearances stated on the heater.

Adequate clearance for servicing this appliance should be considered

before installation, such as changing the anodes, etc.

A minimum clearance of 5” (12.7 cm) from the front of the jacket must

be allowed for access to replaceable parts such as the thermostats,

drain valve and relief valve. Provide 24” (61 cm) front clearance for

servicing and adequate clearance between the jacket top and ceiling

for servicing the fl ue area.

When installing the heater, consideration must be given to proper

location. Location selected should be as close to the wall as

practicable and as centralized with the water piping system as

possible.

FIGURE 4.

If this water heater will be used in beauty shops, barber shops,

cleaning establishments, or self-service laundries with dry cleaning

equipment, it is imperative that the water heater or water heaters

be installed so that combustion and ventilation air be taken from

outside these areas.

Propellants of aerosol sprays and volatile compounds, (cleaners,

chlorine based chemicals, refrigerants, etc.) in addition to being

highly fl ammable in many cases, will also react to form corrosive

hydrochloric acid when exposed to the combustion products of

the water heater. The results can be hazardous, and also cause

product failure.

COMBUSTION AIR AND EXHAUST TERMINATION

CLEARANCES

Venting Through an Outside Wall - Clearances, see Figure 6.

• 0" clearance for 3" PVC, ABS, or CPVC Schedule 40 piping from

combustible surfaces.

• The location selection must provide clearances for servicing and

proper operation of the water heater, see Figure 7.

FIGURE 5.

• The venting system must be installed in a manner which allows

inspection of the installation of the venting pipes and joints as

well as periodic inspection after installation as required by the

National Fuel Gas Code ANSI Z223.1-current edition.