Wire sizes/torque requirements, Mounting, Warning: personal injury – Outback Power Systems FLEXpower TWO Quick Start Guide User Manual

Page 2: Warning: fire/explosion hazard, Important, Fp2 mounting, Ac wire sizes and torque values

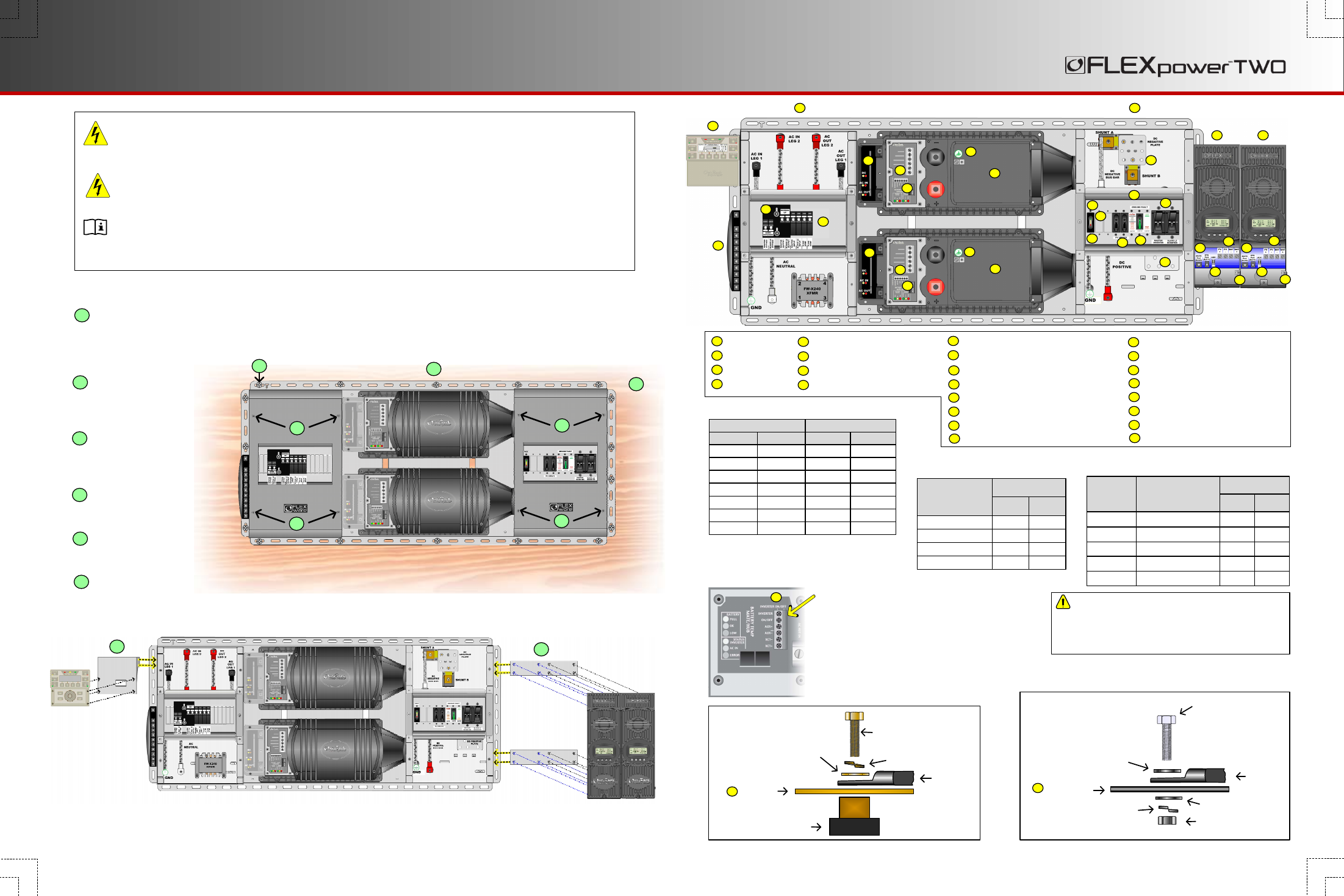

Wire Sizes/Torque

Requirements

AC Circuit Breakers

DC Circuit Breakers

DC Enclosure

Control Wiring Terminal Block:

The Inverter ON/OFF terminals are used for connecting an

external ON/OFF switch. To use this feature, the jumper

must be removed. (See installation manual for details.)

The AUX terminals provide a 12 Vdc signal. The AUX

terminals can be used to start a generator or to control

external devices.

AUX terminals are also available on the charge

controller and the FLEXnet DC. (See the charge

controller or FNDC installation manuals for details.)

Mounting

WARNING: Fire/Explosion Hazard

Do not place combustible or flammable materials within 12 feet (3.7 m) of the equipment. This unit employs mechanical

relays and is not ignition-protected. Fumes or spills from flammable materials could be ignited by sparks.

WARNING: Personal Injury

Use safe lifting techniques and standard safety equipment when working with this equipment.

IMPORTANT:

Clearance and access requirements may vary by location. Maintaining a 36” (91.4 cm) clear space in front of the system

for access is recommended. Consult local electric code to confirm clearance and access requirements for the specific

location.

FP2 Dimensions:

20.25" (51.4 cm) H X 36.5" (92.6 cm) W X 13.5" (34.3 cm) D

900-0152-01-00 Rev A.vsd\Page-2\2013-01-17

©2012 OutBack Power Technologies. All Rights Reserved.

CAUTION: Equipment Damage

When connecting cables from the inverter to the battery

terminals, ensure the proper polarity is observed.

Connecting the cables incorrectly can damage or

destroy the equipment and void the product warranty.

Torque requirements for

the conductor lugs

Circuit

Breaker Stud

Torque

In-lb

Nm

M8

20

2.3

¼ - 20

35

4.0

5/16 - 18

50

5.6

3/8 - 16

225

25.4

AC Wire Sizes and Torque Values

It is recommended that conductors be #6 AWG

THHN copper, or larger, rated to 75°C

(minimum) unless local code requires otherwise.

AWG

In-lb

#14 - 10

20

#8

25

#6 - 4

35

#3

35

#2

40

#1

50

1/0

50

mm

2

2.5 – 6

10

16 – 25

35

35

50

70

Nm

2.3

2.8

4.0

4.0

4.5

5.6

5.6

Wire Size

Torque

Shunt

Bolt 3/8"

Lock Washer

Flat Washer

Battery

Negative (–)

Lug

Negative (–) Battery Cable

Connections

Bolt 3/8"

DC Positive (+)

Plate

Battery

Positive (+)

Lug

Flat Washer

Positive (+) Battery Cable

Connections

Nut

Lock Washer

AC Enclosure

Communication Manager HUB10

DC Enclosure

FLEXmax 80 Charge Controller

1

2

3

4

AC Enclosure

1

2

Master Inverter

Slave Inverter

3

4

6

7

8

9

10

5

6

Mechanical Interlock (Bypass)

7

8

8

MATE3 System Display and Controller

9

10

Charge Controller Terminals

Inverter DC Circuit Breakers

GFDI

PV Input Circuit Breakers

FLEXnet DC (FNDC)

11

12

13

14

15

11

12

13

14

15

15

5

AUX Control Terminals

16

16

16

16

16

Inverter Chassis Ground

DC Positive (+) Plate

17

18

19

Charge Controller Chassis Ground

20

DC Negative (–) Plate

17

18

19

19

20

20

Surge Protector

CC Communication Ports

21

22

23

FNDC Communication Port

24

Inverter Communication Ports

21

21

22

22

23

23

24

FP2 Mounting:

1. Ensure the mounting

surface is strong enough

to handle 3 times the total

weight of all the

components.

2. Using additional people to

assist with lifting, place the

panel on the wall. Ensure

the panel is level.

3. Secure the panel into the

surface using a minimum

of 10 lag bolts (or other

appropriate hardware).

4. Remove the covers from

the AC Enclosure and the

DC Enclosure.

5. Follow the instructions for

installing the bracket for

the MATE3.

6. Follow the instructions for

installing the brackets for

the charge controllers.

1

2

3

4

5

6

1

2

3

4

4

4

4

5

6

Minimum DC Cable based on the

DC Circuit Breaker

Torque

In-lb

Nm

50

5.6

225

25.4

225

25.4

DC

Circuit

Breaker

Cable Size

125

1/0 (70 mm

2

)

175

2/0 (70 mm

2

)

250

4/0 (120 mm

2

)

35

4.0

80

#4 AWG (25 mm

2

)

35

4.0

60

#6 AWG (16 mm

2

)

16

16

DC

Negative (–)

Plate

Flat Washer

18

17