Yetter 2967-035 TITAN Universal Face Plate Mounted Floating Residue Manager User Manual

Page 11

11

MAINTENANCE

STEP 1. Regularly inspect the residue manager for loose or worn bolts. Repair and replace

as needed.

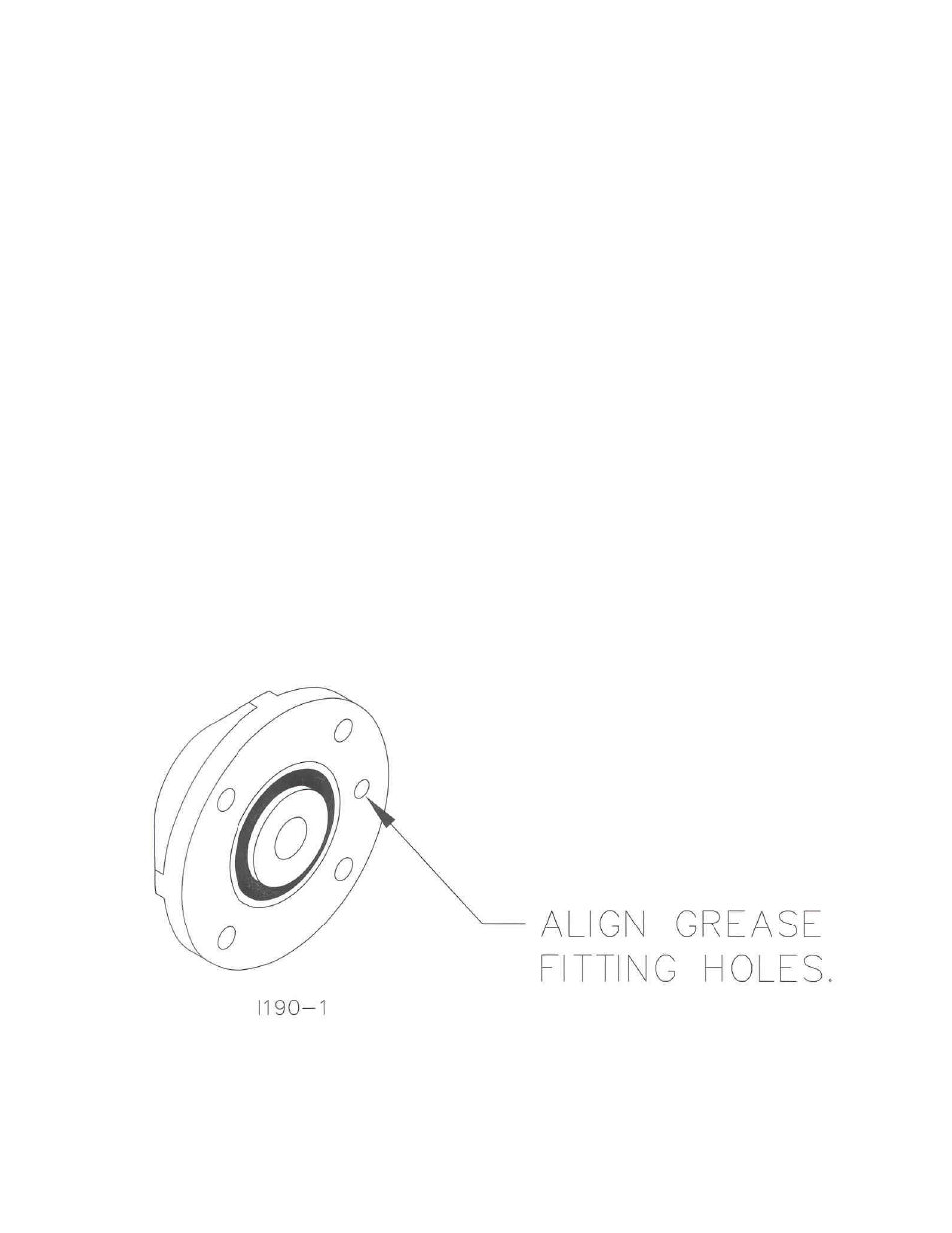

BEARING ASSEMBLY AND LUBRICATION

Practice Safety

Understand and practice safe service procedures before doing work. Follow ALL the

operating, maintenance and safety information in the equipment operator manual.

Clear the area of bystanders, especially small children, when performing any

maintenance or adjustments. Keep work area clean and dry. Use adequate lighting

for the job. Use only tools, jacks and hoists of sufficient capacity for the job.

Never lubricate, service, or adjust machine while it is moving. Keep hands, feet, and

clothing from power-driven moving and rotating parts. Disengage all power and

operate controls to relieve pressure. Lower equipment to the ground, stop the

engine. Remove the key. Wait for all moving parts to stop before servicing,

adjusting, repairing or unplugging.

Securely support any machine elements with blocks or safety stands that must be

raised for service work.

Keep all parts in good condition and properly installed. Fix damaged equipment

immediately. Replace worn or broken parts. Remove any buildup of grease, oil, or

debris.

Make sure all guards are in place and properly secured when maintenance work is

completed.

Assembly