Bolt torque – Yetter 2940-010 Combo User Manual

Page 5

5

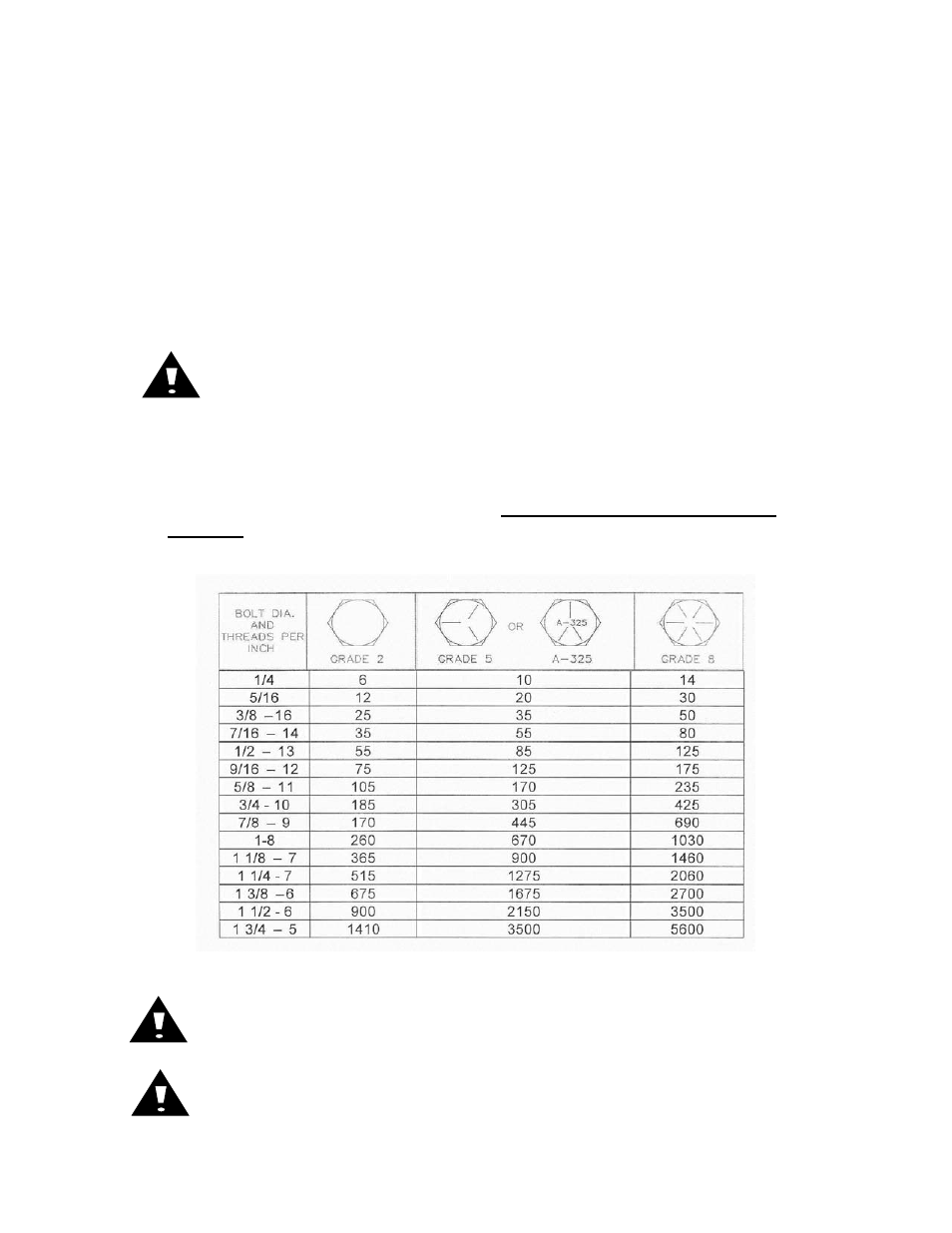

BOLT TORQUE

Mounting bolts and hardware

Before operating the Titan

Residue Manager for the first time, check to be sure that all

hardware is tight. Check all hardware again after approximately 50 hours of operation and at the

beginning of each planting season.

All hardware used on the Titan

Residue Manager is Grade 5 unless otherwise noted. Grade 5

cap screws are marked with three radial lines on the head. If hardware must be replaced, be

sure to replace it with hardware of equal size, strength and thread type. Refer to the torque

values chart when tightening hardware.

Important: Over tightening hardware can cause as much damage as when under

tightening. Tightening hardware beyond the recommended range can reduce its

shock load capacity.

The chart below is a guide for proper torque. Use it unless a specified

torque is called out elsewhere in the manual.

Torque is the force you apply to the wrench handle or the cheater bar,

times the length of the handle or bar. Use a torque wrench whenever

possible.

The following table shows torque in ft. lbs. for coarse thread hardware.

Lubricate all bearings and moving parts as assembled and make certain that they work freely.

WARNING: Never work around the toolbar/implement while in a raised position without

using safety lockups.

CAUTION: The Residue manager attachments are very heavy. Pay extra attention to

lifting techniques while handling and or maneuvering the opener during assembly.

Failure to do so may lead to personal injury.