About this tool, Test procedures, Safety tips – Equus 3614 - Compression Tester Plus (6-piece kit) User Manual

Page 2: Before testing, Reading test results

ABOUT THIS TOOL

The compression tester is a diagnostic tool which can help you

identify worn or damaged pistons, rings, valves and gaskets. A

compression check consists of measuring pressure at each

cylinder at cranking speed. ALWAYS perform a compression

check as part of the tune-up procedure.

TEST PROCEDURES

CAUTION: Engine parts and surrounding areas will be hot.

1. Stop engine. Carefully disconnect all spark plug wires

from spark plugs. Number spark plug wires to aid in

proper reinstallation.

NOTE: To prevent damage to spark plug wires, be

sure to disconnect wires by first twisting then pulling on

the wire's boot and not on the wire itself.

2. Remove all spark plugs and place in order

corresponding to the cylinders from which they were

removed. (This procedure is used to associate cylinder

or compression problems by inspecting the condition

of a malfunctioning cylinder's spark plug.)

NOTE: To prevent thread damage on vehicles with

aluminum heads, wait approximately ten minutes before

removing spark plugs.

3. Locate the intake throttle plate (or carburetor throttle

plate). Secure the plate wide open for testing.

NOTE: You may also have an assistant help you by

holding the accelerator pedal down.

CAUTION: Be sure to return the throttle plate to it's origi-

nal (closed) position after testing or before starting ve-

hicle. Failure to comply can result in serious engine

damage.

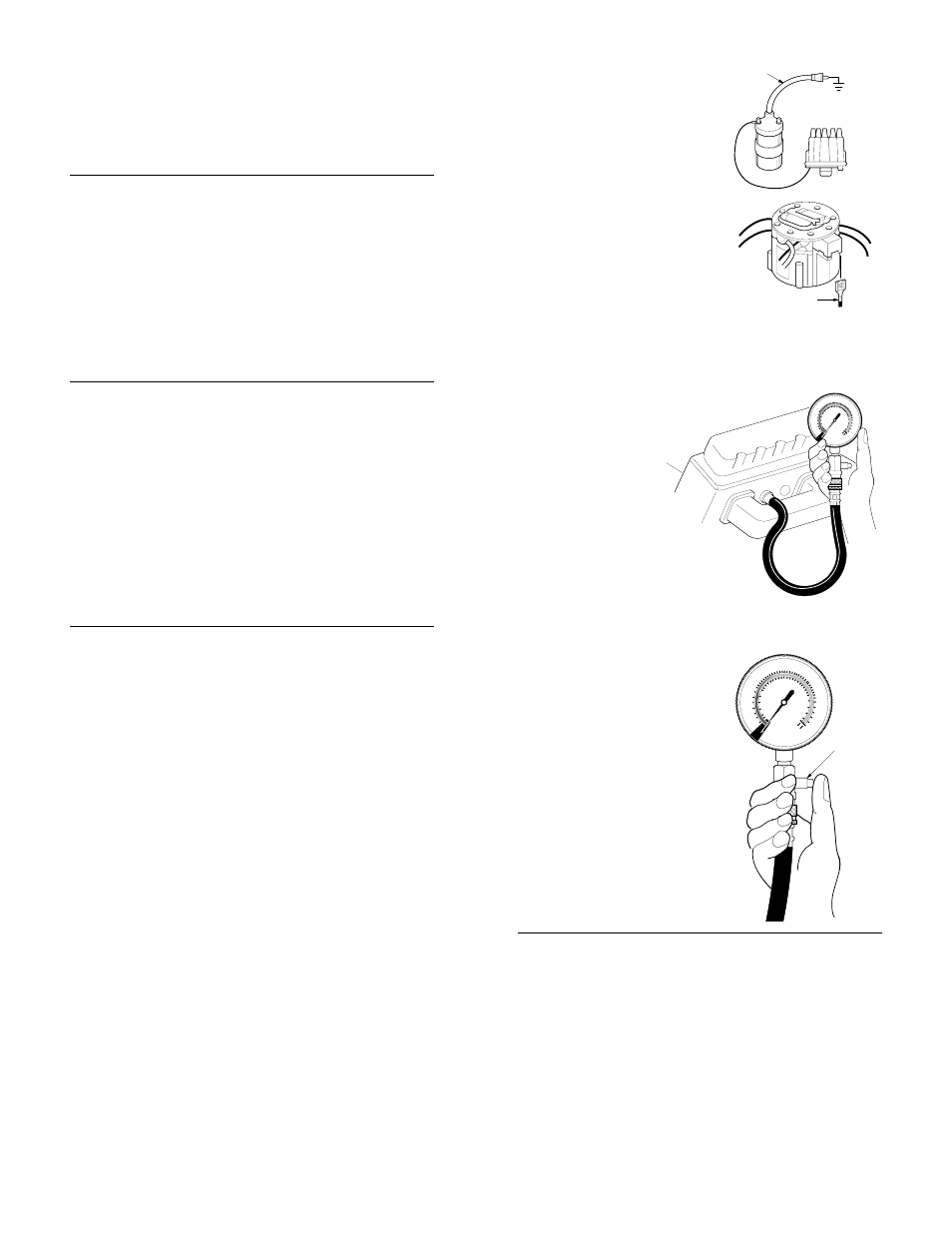

4. Disable the ignition system:

NOTE: These are typical ignition systems. Refer to

your vehicle's service manual for additional information

on your vehicles ignition system and how to safely

disable it.

For electronic or conven-

tional breaker point ignition

systems: Remove the high

tension (coil) wire from the

distributor cap and connect to

a known good ground to avoid

spark discharge, or disconnect

coil primary connector.

For General Motors HEI

systems: Disconnect the

primary (or battery) con-

nection from the distributor

cap and wrap with tape to

avoid accidental grouding.

5. Disconnect the spark plug hose from the compression

gauge. Screw the plug end of the hose into the spark

plug hole. HAND TIGHTEN ONLY.

NOTE: On engines with 14MM long

reach plugs, use the 14 MM

long reach adapter

included in kit. DO

NOT use adapter

in short reach

holes – it may hit

the top of the pis-

ton and damage the

engine.

6. Connect the spark plug hose to

the compression gauge by

means of the "quick connect"

coupling. Make sure the coupling snaps into place.

This ensures the hose is "locked" into the gauge.

7. Crank the engine for at least

five compression strokes.

NOTE: Engine should be

cranked the same number of

strokes for each cylinder.

8. Record the reading from the

compression gauge for

reference. Press the side

release valve to release

pressure from the gauge.

Disconnect the spark plug

hose from the compression

gauge. Connect the hose to

the next cylinder, and repeat

steps 5 through 8 (repeat for

each cylinder to be tested).

COMPRESSION

TESTER

30

60

90

120

150

180

210

240

270

300

0

2

4

6

8

10 12

14

16

18

20

kPa x 100

PSI

0

IEC

COMPRESSION

TESTER

30

60

90

120

150

180

210

240

270

300

0

2

4

6

8

10 12

14

16

18

20

kPa x 100

PSI

0

IEC

RELEASE

VALVE

SAFETY TIPS

1. Always wear safety eye protection.

2. Put transmission in “park” (for automatic) or “neutral”

(for manual). Set parking brake and block drive wheels.

3. Be sure to disable the ignition system to prevent the

car from starting (see TEST PROCEDURES, step 4).

4. This compression tester is designed for use on spark-

ignited gasoline engines which do not exceed 250 psi. Use

of this tool for any other purpose may result in personal

injury, damage to the tool, or damage to your vehicle.

BEFORE TESTING

To ensure that compression readings are accurate,

perform the following pre-test procedures.

1. Make sure the vehicle battery is fully charged, and the

starter system is in good condition.

2. Warm up the engine until normal operating temper-

ature is reached.

3. Be sure to remove ALL spark plugs before performing

the compression test.

4. On carbureted models, open choke plate to allow air

flow through the carburetor during testing (see TEST

PROCEDURES, step 3).

HIGH TENSION

LEAD

CHASSIS GROUND

PRIMARY

WIRE

READING TEST RESULTS

The compression check identifies variations in com-

pression between cylinders. Compression is considered

normal if the lowest compression reading is at least 75%

of the highest reading, as shown in the following example:

Cylinder

Cyl 1

Cyl 2

Cyl 3

Cyl 4

Cyl 5

Cyl 6

Reading

130

125

140

125

130

115

(psi)