Brodix Small Block Chevy Compatible Block User Manual

For buying brodix, Arrant y, Iscl aimer

www.brodix

.com • 301 MAPLE A

VENUE • P

.O. BOX 134

7 • MENA

, AR 7

1953

ORDER, TECH, AND INFORMA

TION: (4

79) 394-1075 • F

AX: (4

79) 394-1996

Not legal for sale or use on pollution contr

olled motor vehicles.

© Copyright 2010 Br

odix, Inc. Revised: 7

/12/10

Not legal for sale or use on pollution contr

olled motor vehicles.

© Copyright 2010 Br

odix, Inc.

General Instructions for Small

Block Chevy Compatible Blocks

W

ARNING!

PLEASE CHECK THE BLOCK THOROUGHL

Y IN EVER

Y POSSIBLE W

A

Y.

IF YOU SUSPECT A DEFECT

, CONT

ACT

BRODIX, INC. OR THE DEALER IT W

AS

PURCHASED FROM BEFORE ANY WORK HAS BEGUN. BRODIX

®

WILL NOT

BE RESPONSIBLE FOR VISIBLE DEFECTS AFTER ANY WORK HAS BEEN ST

AR

TED.

INSPECT THE BLOCK FOR DAMAGE FROM SHIPPING. INSPECT THE BLOCK OIL PASSAGES AND THREADED HOLES.

W

ARNING!

THE SLEEVES ARE LEFT ABOVE THE DECK OF THE BLOCK INTENTIONALL

Y. IT IS THE ENGINE

BUILDER’S PREFERENCE WHETHER OR NOT TO SURF

ACE THE SLEEVES FLA

T WITH THE DECK

OF THE BLOCK.

ALL PLUGS, LOCKS, AND SCREWS MUST HA

VE

ANTI-SEIZE ON THE THREADS.

• The sleeves must be clearanced befor

e initial

installation of crank and r

ods.

• The block must be align honed and checked

for bearing clearance.

• The cylinders must be

fi nish bor

ed and

honed.

• Y

ou must check clearance befor

e the

fi nal installation of crank, r

ods, pistons,

and cam in the block.

• W

ash the block thor

oughly with soap

and water

, and blow dry with air

.

• Install the r

ear cam plug with the o-ring and

snap ring in place.

• Install all r

equir

ed water and oil plugs.

See Diagram A and B.

• Apply anti-seize to all main and head stud thr

eads

befor

e installation. Hand tighten only

.

The BRODIX

®

cam bearing, part number

8B CAM BEARING, uses thr

ee 1/4 inch allen head

cap scr

ews to lock the center thr

ee bearings in place.

The allen head cap scr

ews must be

fi tted for the

pr

oper length. The fr

ont and the r

ear bearing

will use spiral locks. Roller bearings ar

e held

into place on both sides with spiral locks.

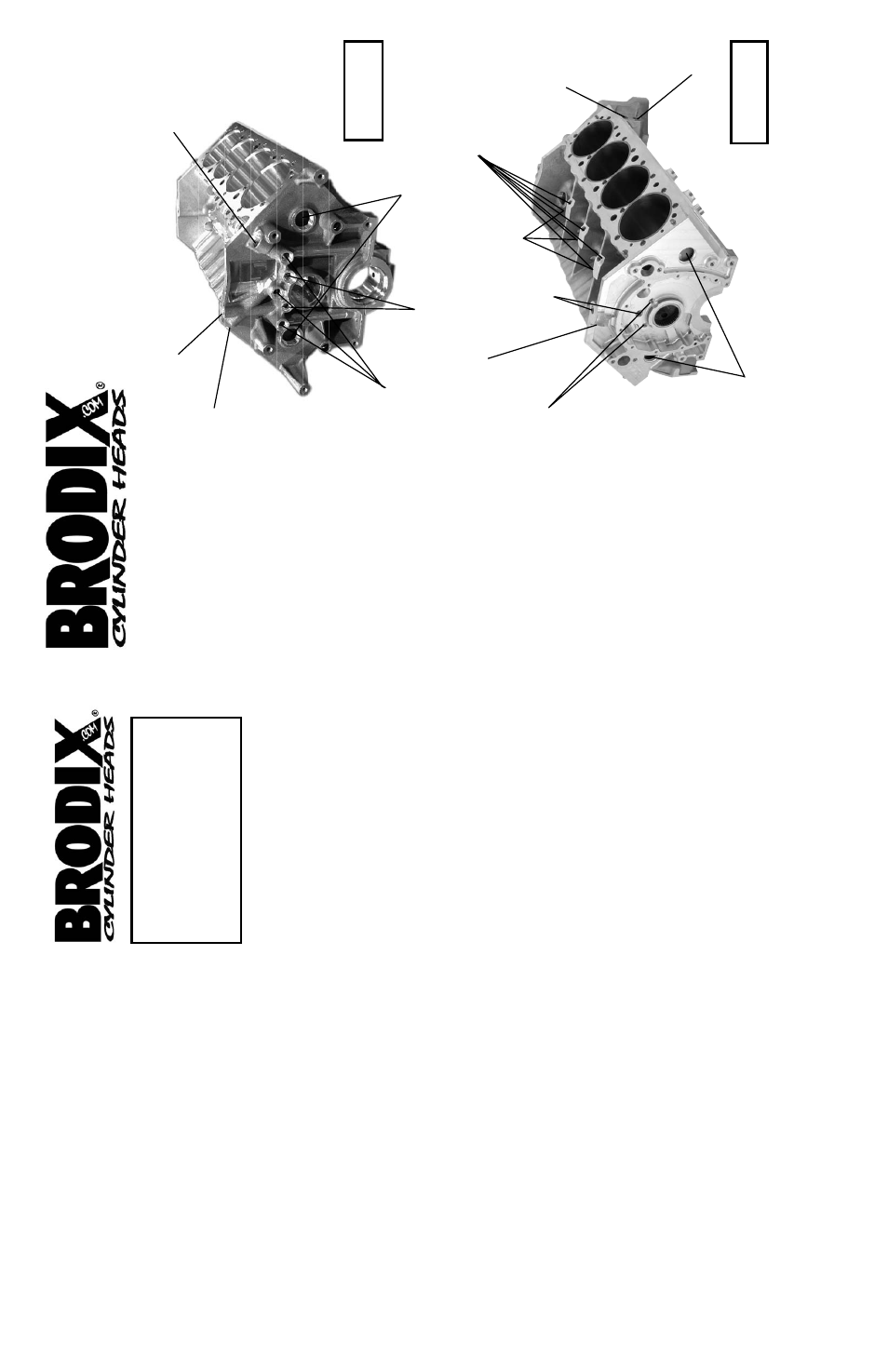

Diagram B

(Fr

ont)

W

ARNING!

PLEASE BE ADVISED THA

T HEA

T SOAKING AN

ALUMINUM BLOCK ABOVE 250° F CAN DRASTICALL

Y

AFFECT THE HARDNESS.

CLEANING TECHNIQUES THA

T UTILIZE HEA

T ARE NOT

RECOMMENDED.

Please feel fr

ee to call or write if ther

e ar

e any pr

oblems

or questions. W

e have a complete r

epair service available if block

damage occurs.

No warranties of any natur

e (expr

essed, implied,

fi tness of usage or mer

chantability) ar

e given on these pr

oducts. Seller

undertakes no r

esponsibility for any pr

oduct sold. Additional disclaimers ar

e within and ar

e binding upon this contract. Due

to the intended usage of pr

oducts of

fer

ed, all pr

oducts ar

e sold on an “as-is” basis, and no warranties of any kind, whether

written or oral ar

e made by BRODIX, Inc., its agents or employees. All implied warranties, including the implied warranties

of mer

chantibility and

fi tness ar

e expr

essly excluded, and the buyer bears the entir

e risk as to quality performance and use

of these pr

oducts. BRODIX, Inc. will assume no r

esponsibility of personal injury

, labor or other injury arising out of the us-

age of high performance racing parts or pr

oducts. Any defective part will be handled between the original manufactur

er and

the buyer

. BRODIX, Inc. r

eserves the right to change speci

fi cations, prices and discontinue parts without notice. Installation

of BRODIX heads may adversely af

fect the vehicle manufactur

er’

s warranties, and may violate State and Federal laws when

vehicles so equipped ar

e operated other than strictly of

f-highway

. BRODIX r

eserves the right to discontinue any pr

oduct at its

sole discr

etion and without any liability with r

espect to similar pr

oducts alr

eady in the

fi eld. Some parts ar

e not legal for sale

or use on pollution contr

olled motor vehicles.

IF YOU NEED TECHNICAL ASSIST

ANCE, CALL

(479) 394-1075

Thank Y

ou

For Buying BRODIX!

W

ARRANT

Y

D

ISCL

AIMER

WHILE OUR PRODUCTS ARE USED ON MANY SUPER-CHARGED APPLICA

TIONS

SUCCESSFULL

Y, PLEASE BE A

W

ARE THA

T THERE IS A GREA

TER POTENTIAL

FOR ENGINE DAMAGE DUE TO THE POSSIBILITY OF TUNING ERRORS.

PRICES ARE SUBJECT TO CHANGE WITHOUT NOTICE.

AL

W

A

YS CONFIRM PRICE WHEN PLACING YOUR ORDER.

WE WILL MAKE EVER

Y EFFOR

T TO KEEP YOU INFORMED OF INCREASES.

www.brodix

.com • 301 MAPLE A

VENUE • P

.O. BOX 134

7 • MENA

, AR 7

1953

ORDER, TECH, AND INFORMA

TION: (4

79) 394-1075 • F

AX: (4

79) 394-1996

Oil Feed Location on Dry Sump

Application (1/2 Pipe Plug Requir

ed

for W

et Sump Application)

Oil Restrictor

Locations

1/4 Pipe

1/4 Pipe Plug

1/4 Cam Lock Locations

(Standar

d Cam Bearings Only)

Oil Filter Inlet for W

et

Sump Block (1/2 Pipe

Plug Requir

ed for Dry

Sump Application)

Oil Filter Outlet for W

et Sump Block

(1/2 Pipe Plug Requir

ed if Oil Is Fed

at Fr

ont of Block)

1 5/16 Hexed O-Ring

W

ater Plugs

3/8 Pipe Plug

1 5/16 Hexed O-Ring

W

ater Plugs

AN -6 O-Ring Plug

AN -7 O-Ring Plug

1/4 Pipe Plug

Oil Pr

essur

e

-10 O-Ring Plug for

W

et Sump Use

(Use as a Scavenge

Retur

n for Dry Sump)

Diagram

A

(Back)

BRODIX

®

STOCKS A

FULL LINE OF

REPLACEMENT AND

REP

AIR P

AR

TS.