Up to 96% thermal efficiency,direct vent – A.O. Smith BTH-120 through BTH-500 User Manual

Page 4

UP TO 96% THERMAL EFFICIENCY,DIRECT VENT

SUGGESTED SPECIFICATION

(Natural or Propane) gas water heater(s) shall be A. O. Smith Cyclone Xi model # _________ or equal, with up to 96% thermal efficiency, a storage capacity of

______ gallons, an input rating of __________ BTUs per hour, a recovery rating of ___________ gallons per hour (gph) at 100° F rise and a maximum hydrostatic

working pressure of 160 PSI. Water heater(s) shall: 1. Have seamless glass-lined steel tank construction, with glass lining applied to all water-side surfaces

after the tank has been assembled and welded; 2. Have a spiral-shaped heat exchanger placed entirely inside the tank, which shall be glass-lined to protect

against acidic flue gas condensate; 3. Have foam insulation and an ASME-rated temperature and pressure relief valve; 4. Have a down-fired power burner

designed for precise mixing of air and gas for optimum efficiency, requiring no special calibration on start-up; 5. Be approved for 0˝ clearance to combustibles.

Heater shall be supplied with maintenance-free powered anode.

The control shall be an integrated solid-state temperature and ignition control device with integral diagnostics, graphic user interface, fault history display, and

shall have digital temperature readout.

The water heater(s) shall: 1. Be design-certified by UL (Underwriters Laboratories), according to ANSZ21.10 standards governing storage-type water heaters; 2. Meet

ASHRAE/IESNA 90.1-1999; 3. Be design-certified by Underwriters Laboratories for 180° F (62° C) water; 4. Meet SCAQMD Rule 1146.2 for low-NOx emissions.

For conventional-vent specification: The BTH-120 - 250 water heater(s) shall be suitable for venting in 3˝ PVC pipe for a total equivalent distance of 50 ft

and 4˝ PVC pipe for a total equivalent distance of 120 ft.

The BTH-300 - 500 water heater(s) shall be suitable for venting only in 4˝ PVC pipe, for a total equivalent distance of 70 ft.

For sealed-combustion direct-vent specification: The BTH-120 - 250 water heater(s) shall be suitable for venting with (3˝ or 4˝) _______ diameter PVC pipe for a

total equivalent distance of (50 ft or 120 ft) ________ feet. [Alternative venting: the heater(s) shall be suitable for sealed combustion direct venting using a (3˝ or 4˝)

________ diameter PVC exhaust pipe for a total distance of (50 ft or 120 ft) ________ equivalent feet of vent and (50 ft or 120 ft) _______ equivalent feet of intake.]

The BTH-300 - 500 water heater(s) shall be suitable for sealed combustion direct-vent using only 4˝ diameter PVC pipe and 4˝ diameter PVC exhaust pipe for a

total equivalent distance of 70 ft.

Operation of the water heater(s) in a closed system where thermal expansion has not been compensated for (with a properly sized thermal expansion tank) will

void the warranty.

ACGSS02407

Page 4 of 4

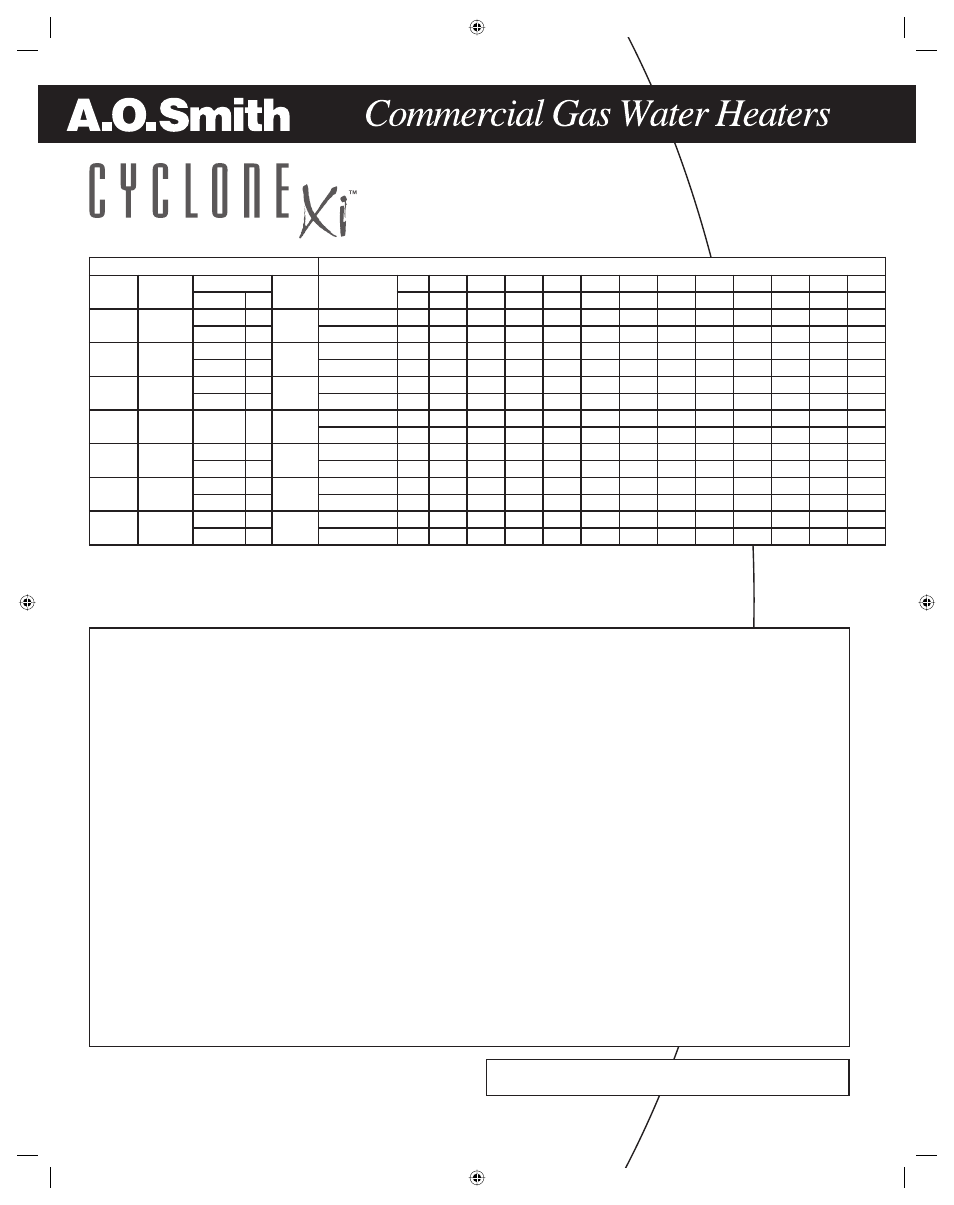

U.S. Gallons/Hr and Litres/Hr at TEMPERATURE RISE INDICATED

MODEL

TYPE OF

GAS

INPUT

Thermal

Efficiency

Approx.

Capacity

Fº

30 Fº

40 Fº

50 Fº

60 Fº

70 Fº

80 Fº

90 Fº

100 Fº

110 Fº

120 Fº

130 Fº

140 Fº

BTUH

KW

Cº

17 Cº

22 Cº

28 Cº

33 Cº

39 Cº

44 Cº

50 Cº

56 Cº

61 Cº

67 Cº

72 Cº

78 Cº

BTH 120

NATURAL/

PROPANE

120,000

95%

60 U.S. Gal

GPH

461

345

276

230

197

173

154

138

126

115

106

99

35

227 Litres

LPH

1744

1308

1046

872

747

654

581

523

476

436

402

374

BTH 150

NATURAL/

PROPANE

150,000

95%

100 U.S. Gals. GPH

576

432

345

288

247

216

192

173

157

144

133

123

44

379 Litres

LPH

2179

1635

1308

1090

934

817

726

654

594

545

503

467

BTH 199

NATURAL/

PROPANE

199,900

95%

100 U.S. Gals. GPH

767

575

460

384

329

288

256

230

209

192

177

164

58

379 Litres

LPH

2904

2178

1743

1452

1245

1089

968

871

792

726

670

622

BTH 250

NATURAL/

PROPANE

250,000

95%

100 U.S. Gals. GPH

960

720

576

480

411

360

320

288

262

240

221

206

73

379 Litres

LPH

3632

2724

2179

1816

1557

1362

1211

1044

991

908

838

778

BTH 300

NATURAL/

PROPANE

300,000

96%

130 U.S. Gals. GPH

1164

873

699

582

499

436

388

349

318

291

269

250

88

492 Litres

LPH

4406

3304

2644

2203

1888

1652

1469

1322

1201

1102

1017

945

BTH 400

NATURAL/

PROPANE

399,900

96%

130 U.S. Gals. GPH

1552

1164

931

776

665

582

517

465

423

388

359

332

117

492 Litres

LPH

5875

4406

3525

2938

2518

2203

1958

1759

1602

1469

1356

1259

BTH 500

NATURAL/

PROPANE

499,900

95%

130 U.S. Gals. GPH

1919

1439

1151

959

822

720

640

576

523

480

443

411

146

492 Litres

LPH

7263

5447

4358

3631

3113

2724

2421

2179

1981

1816

1676

1556

Recovery capacities are based on heater performance at 95% and 96% thermal efficiency.

Add "A" to model number when ordering ASME. Optional on 120 - 250 models. Standard on 300 - 500 models.

Maximum gas supply pressure for 120 - 250: 10.5" w.c. natural gas 14" w.c propane. Maximum gas supply pressure for 300-500 10" w.c. natural gas 13" w.c. propane.

Manifold pressure: 4" w.c. natural gas 10" w.c. propane. Electrical requirements: 120 VAC, Blower 2.2 Amps FL, Igniter 4.0 Amps.

RECOVERY CAPACITY

For Technical Information and Automated Fax Service, call 800-527-1953.

A. O. Smith reserves the right to make product changes or improvements without prior notice.

.

A

.

S

.

U

n

i

d

e

t

n

i

r

P

July 2007R

December 2007R

188427_ACGSS02407.indd 4

12/7/07 9:26:23 AM