Gas requirements, Warning, Gas dryers) – Alliance Laundry Systems LES37A User Manual

Page 18

16

504607

Gas Requirements . . .

(Gas Dryers)

NOTE: The gas service to a gas dryer must conform

with the local codes and ordinances, or in the

absence of local codes and ordinances, with the

latest edition of the National Fuel Gas Code ANSI

Z223.1/NFPA 54 or the CAN/CGA-B149, National

Gas Installation Code.

Natural Gas, 1,000 Btu/ft

3

(37.3 MJ/m

3

) service must

be supplied at 6.5 ± 1.5 inch water column pressure.

For proper operation at altitudes above 2,500 feet (760

m) the natural gas valve spud orifice size must be

reduced to ensure complete combustion. See table at

right.

L.P. (Propane) Gas, 2,500 Btu/ft

3

(93.1 MJ/m

3

)

service must be supplied at 10 ± 1.5 inch water column

pressure.

NOTE: DO NOT connect the dryer to L.P.

(Propane) Gas Service without converting the gas

valve. An LPK1 Sales Accessory (L.P. [Propane]

Gas Conversion Kit 649P3) must be installed.)

NOTE: The dryer and its appliance main gas valve

must be disconnected from the gas supply piping

system during any pressure testing of that system at

test pressures in excess of 1/2 psi (3.45 kPa). (See

illustration on page 10.)

The dryer must be isolated from the gas supply piping

system by closing the equipment shut-off valve during

any pressure testing of the gas supply piping system at

test pressures equal to or less than

1/2 psi (3.45 kPa)

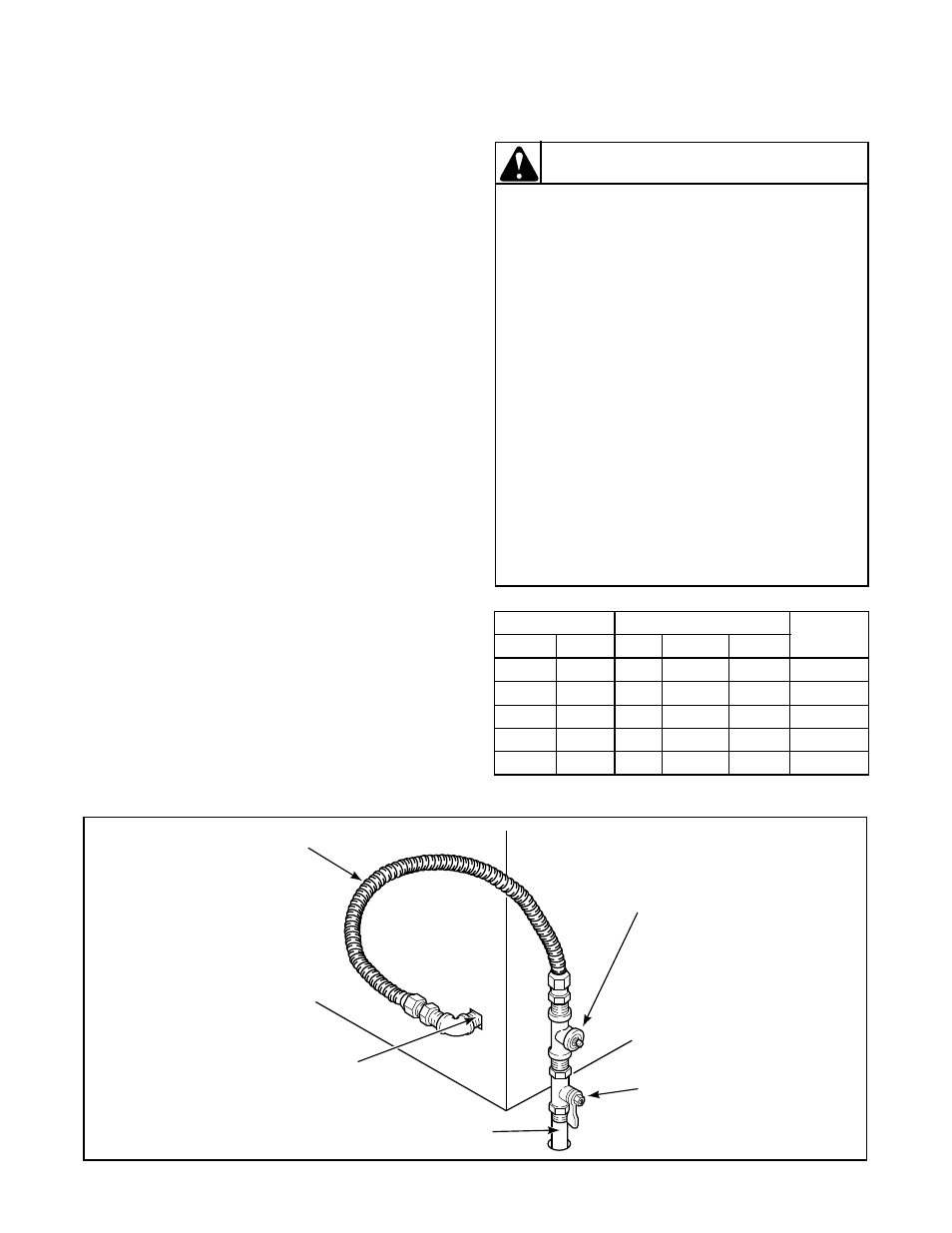

NOTE: When connecting to a gas line, an

equipment shutoff valve must be installed within 6'

(1.8 m) of the dryer. An 1/8" N.P.T. pipe plug must

be installed as shown. See illustration.

Altitude

Orifice Size

Part

Number

ft

m

#

Inches

mm

3000

915

43

0.0890

2.26

503778

6000

1830

44

0.0860

2.18

58719

8000

2440

45

0.0820

2.08

503779

9000

2740

46

0.0810

2.06

503780

10000

3050

47

0.0785

1.99

503781

To reduce the risk of gas leaks, fire or

explosion:

• The dryer must be connected to the type

of gas as shown on nameplate located in

the door recess.

• Use a new flexible stainless steel

connector.

• Use pipe joint compound insoluble in LP

(propane) Gas, or Teflon tape, on all pipe

threads.

• Purge air and sediment from gas supply

line before connecting it to the dryer.

Before tightening the connection, purge

remaining air from gas line to dryer until

odor of gas is detected. This step is

required to prevent gas valve

contamination.

• Do not use an open flame to check for gas

leaks. Use a non-corrosive leak detection

fluid.

W114R1

WARNING

D233IE2E

3/8" NPT

GAS CONNECTION

1/8" NPT

PIPE PLUG

(For checking

inlet gas pressure)

NEW

STAINLESS

STEEL

FLEXIBLE

CONNECTOR

USE ONLY

IF ALLOWED

BY LOCAL

CODES

(Use

Design A.G.A.

Certified

Connector)

EQUIPMENT

SHUT-OFF

VALVE

Installed within

6' (1.8 m) of dryer

BLACK IRON PIPE

Shorter than 20' (6.1 m) - use 3/8" pipe

Longer than 20' (6.1 m) - use 1/2" pipe