Stationary bowl mixer – AMF Stationary Bowl Mixer (SBM) User Manual

Page 2

For more information please call

your Account Manager or

1-800-BAKERS-1.

Headquarters

AMF Bakery Systems

2115 West Laburnum Avenue

Richmond, Virginia 23227

1-800-225-3771 or 804-355-7961

FAX: 1-804-342-9724

www.amfbakery.com

European operation

West Park Ring Road

Leeds LS16 6QQ England

Tel.: 1132-787110

Fax: 1132-741415

STATIONARY BOWL MIXER

•

Nema 12 remote enclosure (painted steel) including:

Square D main breaker.

Full voltage magnetic Nema rated starters.

Pre-wired terminal strip.

•

Operator panel contains the following:

Eagle digital plug-in timers for high and low speed.

Eagle digital plug-in refrigeration timer.

Digital bowl temperature indicator.

Allen Bradley push-buttons for the following functions:

Mixing (slow, fast, stop)

Door (up, down, stop)

Flour gate (open, close)

Refrigeration selector OFF/ON/AUTO

Alarm (acknowledge/reset)

Safety/jog

Emergency stop

•

Nema 1 Gemco cam switch.

•

Nema 12 junction box, terminal blocks, prewired motors

and controls.

•

Bowl door gearhead motor with electric brake and components.

•

Weg drive motor (copper rotor) integral mount with

NORD Gear reducer.

•

Motor overheat protection installed in stator winding.

•

High/low speed jog operation with special anti-jog function.

•

CAD produced electrical wiring diagram.

•

Equipment meets OSHA requirements.

Bowl And Cooling Jacket

•

All stainless steel one piece bowl construction.

•

Bowl plate 5/16” thick.

•

Bowl end plate 3/8” thick jacketed.

•

Bowl jacket 1/4” “L” type breaked & welded.

•

Reinforcement belts are added to the bowl jacket for

maximum resistance to shock.

•

Refrigerated bowl sides.

•

Bowl insulated with urethane foam.

•

Stainless steel bowl drain valve.

•

D.X. expansion valves or Glycol valves are included.

•

Bowl tested at 250 PSI.

Top Assembly

•

Solid stainless steel.

•

The 12” diameter pneumatic sliding flour gate

•

Two 2” stainless steel sanitary liquid inlets.

Door and Door Shaft Assembly

•

Reinforced stainless steel door.

•

Air operated door seals.

•

Door racks and pinions.

Agitator and Drive Assembly

•

Solid stainless steel “Y” type spiders split at main shaft and

agitator bars.

•

Stainless steel primary agitator bars mounted on lubrication

free U.H.M.W. bushings.

•

Stainless steel secondary agitator bars mounted on lubrication

free U.H.M.W. bushings.

•

Solid stainless steel main shaft mounted on spherical bearings.

•

Sanitary split seal assembly.

•

Agitator is chain and sprocket driven.

•

Chain lubrication by oil bath.

•

Standard agitator RPM 35/70 (consult for other RPM available).

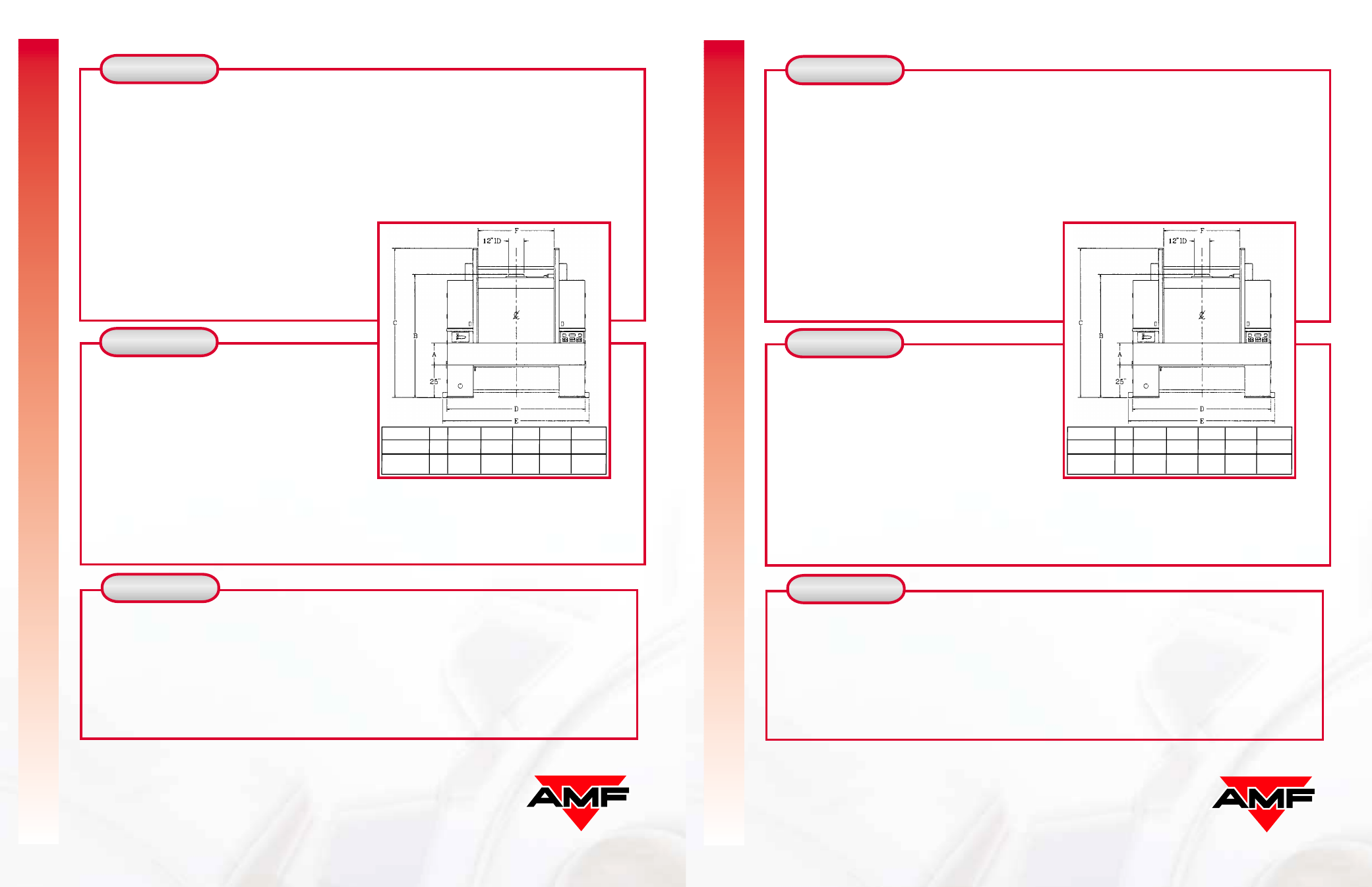

MIXER

59-

1

/

8

"

9' - 0"

9' - 6

3

/

4

"

9' - 6

1

/

4

"

7' - 10

5

/

8

"

17"

2000 &

2400 lb.

54-

1

/

8

"

8' - 7"

9' - 5

3

/

4

"

9' - 1

1

/

4

"

7' - 7

5

/

8

"

16"

1600 lb.

A

B

C

D

E

F

Mechanical Options

•

Extra liquid inlet.

•

12” O.D. butterfly valve in lieu of sliding flour gate.

•

Stainless steel air operated front sliding type sponge door.

•

Stainless steel air operated rear hinge type sponge door.

•

Stainless steel ingredient door with safety bars.

•

Stainless steel refrigerated door (with hoses and valves).

•

Double extra heavy stainless steel primary agitator bars

(5/8” wall) 4” O.D.

•

Anti-vibration pad.

•

Belt drive.

Electrical Options

•

Eagle digital salt timer with alarm.

•

Newport digital thermometer.

•

Ampmeter.

•

Total time clock (mounted in remote enclosure).

•

Nema 4 gemco cam switch in lieu of Nema I.

•

Allen Bradley programmable controller SLC 500 series.

•

Allen Bradley PanelView 550 operator interface.

•

Ampmeter (displayed on operator interface).

•

Wattmeter (displayed on operator interface).

Mechanical

Specifications

Electrical

Specifications

Options

08/2002

13-K-07

AMF’s continuing engineering is constantly improving product performance. Consequently machinery specifications are subject to change without notice.

For more information please call

your Account Manager or

1-800-BAKERS-1.

Headquarters

AMF Bakery Systems

2115 West Laburnum Avenue

Richmond, Virginia 23227

1-800-225-3771 or 804-355-7961

FAX: 1-804-342-9724

www.amfbakery.com

European operation

West Park Ring Road

Leeds LS16 6QQ England

Tel.: 1132-787110

Fax: 1132-741415

STATIONARY BOWL MIXER

•

Nema 12 remote enclosure (painted steel) including:

Square D main breaker.

Full voltage magnetic Nema rated starters.

Pre-wired terminal strip.

•

Operator panel contains the following:

Eagle digital plug-in timers for high and low speed.

Eagle digital plug-in refrigeration timer.

Digital bowl temperature indicator.

Allen Bradley push-buttons for the following functions:

Mixing (slow, fast, stop)

Door (up, down, stop)

Flour gate (open, close)

Refrigeration selector OFF/ON/AUTO

Alarm (acknowledge/reset)

Safety/jog

Emergency stop

•

Nema 1 Gemco cam switch.

•

Nema 12 junction box, terminal blocks, prewired motors

and controls.

•

Bowl door gearhead motor with electric brake and components.

•

Weg drive motor (copper rotor) integral mount with

NORD Gear reducer.

•

Motor overheat protection installed in stator winding.

•

High/low speed jog operation with special anti-jog function.

•

CAD produced electrical wiring diagram.

•

Equipment meets OSHA requirements.

Bowl And Cooling Jacket

•

All stainless steel one piece bowl construction.

•

Bowl plate 5/16” thick.

•

Bowl end plate 3/8” thick jacketed.

•

Bowl jacket 1/4” “L” type breaked & welded.

•

Reinforcement belts are added to the bowl jacket for

maximum resistance to shock.

•

Refrigerated bowl sides.

•

Bowl insulated with urethane foam.

•

Stainless steel bowl drain valve.

•

D.X. expansion valves or Glycol valves are included.

•

Bowl tested at 250 PSI.

Top Assembly

•

Solid stainless steel.

•

The 12” diameter pneumatic sliding flour gate

•

Two 2” stainless steel sanitary liquid inlets.

Door and Door Shaft Assembly

•

Reinforced stainless steel door.

•

Air operated door seals.

•

Door racks and pinions.

Agitator and Drive Assembly

•

Solid stainless steel “Y” type spiders split at main shaft and

agitator bars.

•

Stainless steel primary agitator bars mounted on lubrication

free U.H.M.W. bushings.

•

Stainless steel secondary agitator bars mounted on lubrication

free U.H.M.W. bushings.

•

Solid stainless steel main shaft mounted on spherical bearings.

•

Sanitary split seal assembly.

•

Agitator is chain and sprocket driven.

•

Chain lubrication by oil bath.

•

Standard agitator RPM 35/70 (consult for other RPM available).

MIXER

59-

1

/

8

"

9' - 0"

9' - 6

3

/

4

"

9' - 6

1

/

4

"

7' - 10

5

/

8

"

17"

2000 &

2400 lb.

54-

1

/

8

"

8' - 7"

9' - 5

3

/

4

"

9' - 1

1

/

4

"

7' - 7

5

/

8

"

16"

1600 lb.

A

B

C

D

E

F

Mechanical Options

•

Extra liquid inlet.

•

12” O.D. butterfly valve in lieu of sliding flour gate.

•

Stainless steel air operated front sliding type sponge door.

•

Stainless steel air operated rear hinge type sponge door.

•

Stainless steel ingredient door with safety bars.

•

Stainless steel refrigerated door (with hoses and valves).

•

Double extra heavy stainless steel primary agitator bars

(5/8” wall) 4” O.D.

•

Anti-vibration pad.

•

Belt drive.

Electrical Options

•

Eagle digital salt timer with alarm.

•

Newport digital thermometer.

•

Ampmeter.

•

Total time clock (mounted in remote enclosure).

•

Nema 4 gemco cam switch in lieu of Nema I.

•

Allen Bradley programmable controller SLC 500 series.

•

Allen Bradley PanelView 550 operator interface.

•

Ampmeter (displayed on operator interface).

•

Wattmeter (displayed on operator interface).

Mechanical

Specifications

Electrical

Specifications

Options

08/2002

13-K-07

AMF’s continuing engineering is constantly improving product performance. Consequently machinery specifications are subject to change without notice.