Nilfisk-ALTO 590 User Manual

Page 10

Page 10

Clarke

®

Model 590/590B Operator's Manual

MAINTENANCE

WARNING:

To prevent electric shock, always re-

move the electrical plug from the electri-

cal outlet before doing any repairs or

maintenance to this machine.

WARNING:

Maintenance procedures must be done

only by persons authorized to do mainte-

nance.

NOTE: For safe operation, and longer life of your Clarke

product, use only Clarke replacement parts.

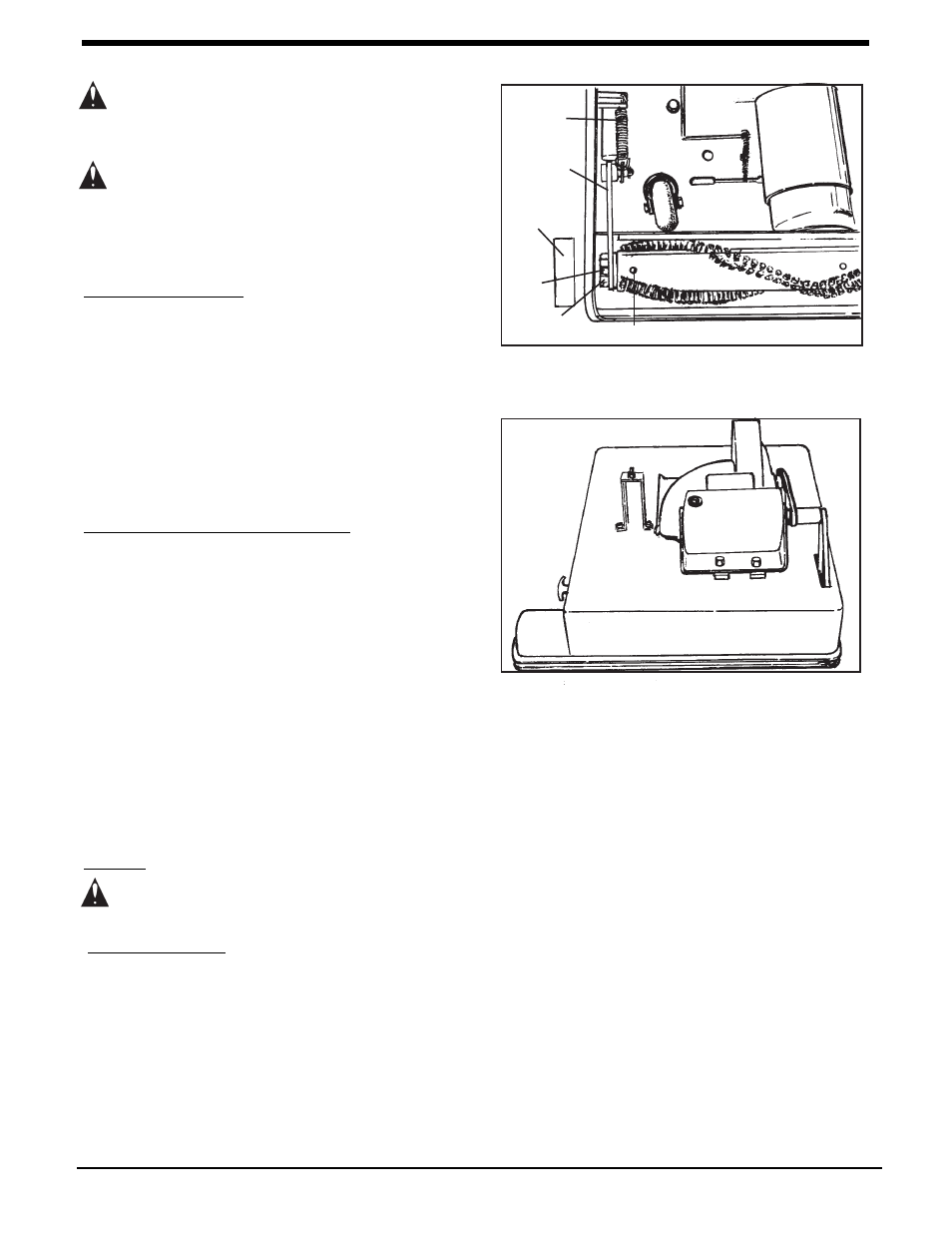

How To Adjust The Belts

The belt to drive the brush: The tension of this belt is controlled

by a spring. If necessary, replace the spring and the belt. See

figure 6

The belt to drive the vacuum impeller: The tension of this belt

is controlled by the position of the motor. To get access, remove

the main cover of the machine. Loosen the four hex screws that

fasten the motor, and move the motor forward or backward.

Tighten the four hex head screws forward or backward. Tighten

the four head screws and install the cover of the machine.

See figure 7.

How To Get More Use From The Brushes

When the brush becomes worn, rotate the brush shaft to get

more use. When the brushes becomes worn more, replace the

two halves of the brush.

To rotate the brush shaft, follow this procedure:(See figure 6)

1. Remove the electrical plug from the outlet.

2. Put the machine upside down.

3. Remove the side shoe (3) from the left-handed end of the

brush shaft.

4. Loosen the retainer (4) and the spacer (5) on the end of the

brush shaft.

5. Rotate the brush shaft ½ (180°) turn.

6. Tighten the retainer (4).

7. Install the side shoe.

To change the two halves of the brush, remove the screws (6).

Replace the brush section and the screws. See figure 6

Electrical

WARNING:

Electrical repairs must be made by autho-

rized personnel only.

MOTOR AND CIRCUIT

The Model 590 has a capacitor start, induction run motor.

The Model 590B has a permanent magnet motor. This motor

has carbon brushes. The brushes and commutator should be

inspected annually for damage and/or wear.

This motor needs no maintenance. If damage occurs to the

motor, return the machine to a Clarke authorized repair location.

If damage occurs to the electrical circuit, make sure the ma-

chine is repaired by an authorized person. The machine must

be tested for electrical safety before it is used again.

Figure 6

Figure 7

2. Spring

1. The Belt

to Drive

the brush

3.

4.

5.

6.