Noby UK Noby-220 2-Zone User Manual

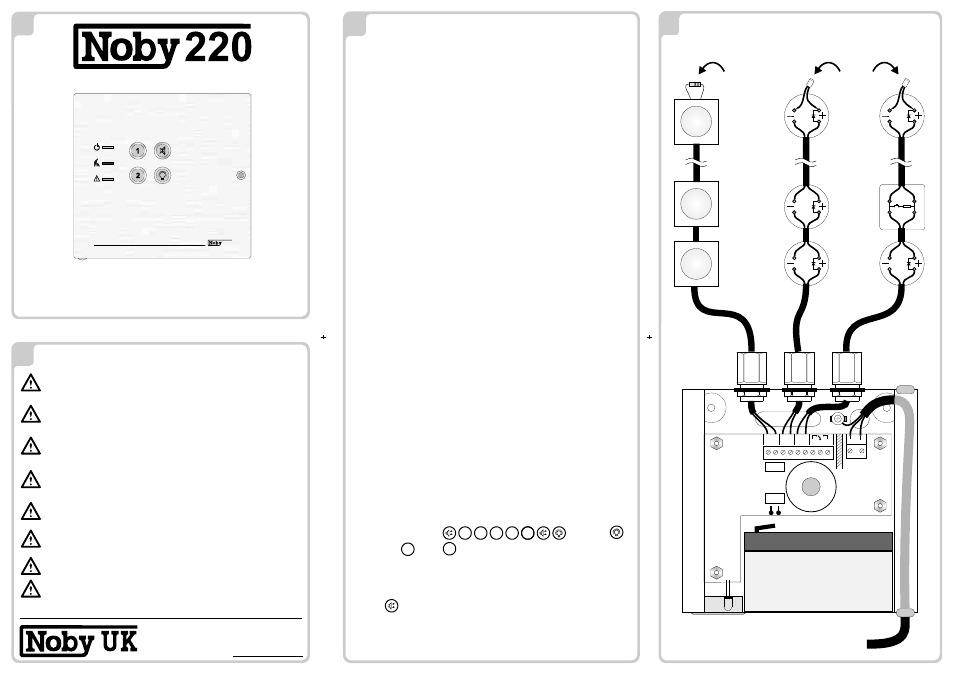

Installation instructions, 3installation and commissioning, 4figure 1 system connections

Where to site the Noby-220

It is intended that the Noby-220 be located in a public space indoors, such as a hallway or

landing area, where the LED alarm strobe can be seen and the internal alarm sounder can

be clearly heard. Another consideration is to position the panel to make most effective use

of the LED courtesy-light, which automatically operates in the event of a power cut.

Connecting the mains supply

Mains power may be supplied via a permanently wired cable supplied from a 2A fused spur,

and in accordance with local wiring regulations. Feed the cable securely either through the

cable-entry hole CE2, or via a 20mm cable gland CG3.

Alternatively a flexible mains cord can be fitted with a 2A fused plug, and fed in through

CG4 or CG5 using the strain relief bush supplied (suitable for diameters 6.2mm to 7.4mm).

SAFETY: strip back the outer sheath of the cable no more than 25mm and then strip

back each inner core to reveal 6mm bare conductor. In this way the cable's double

insulation is preserved inside the box to within 25mm of the screw terminal block.

EARTH: the Noby-220 is designated Class-1 equipment and must be earthed. Connect

the earth core of the mains cable to the earthing point on the box-back. Note that there is

no requirement (and therefore no provision is made) to earth the lid provided the mains

cores are prepared in the manner described above. Refer to a qualified electrician if there

is any doubt concerning electrical safety.

First power up

It is recommended that the Noby-220 is first powered up with the End Of Line devices still

connected to the screw terminal block at the panel, as supplied from the factory. This will

help to establish that the panel is functioning OK before connecting any external devices.

!

Isolate the mains supply.

!

Position the battery as shown in Fig.1, with the -'ve terminal to the rear of the box.

!

Connect the battery terminals observing strict battery polarity.

!

The panel springs into life with an audible warning beep.

!

The absence of mains power causes the green Power LED to flash every 4 secs.

!

The LED courtesy-light is automatically activated due to there being no mains power.

!

Switch on the mains supply to the panel.

!

The Power LED now blinks (occults) every 4 secs, indicating mains-loss memory.

!

Perform a System Reset (refer to User Operation).

!

The panel should now be in standby mode with a steady Power LED and backlight.

Connecting the detectors

!

Up to a maximum of 10 detectors can be connected to each zone.

!

There is no restriction on the number of call-points.

!

Ensure that the detectors are within specification at 10.5 volts.

!

Use detector bases fitted with a schottky diode.

!

Connect the detectors and call-points in a straight daisy-chain manner.

!

The recommended maximum cable length on each circuit is 100m.

!

Maintain strict polarity from the panel, and from one detector to the next.

!

Remove & re-connect the factory fitted EOLC at the farthermost detector base.

Connecting the external sounders

!

The recommended maximum external sounder circuit current is 200mA.

e.g. up to 10 sounders can be connected with a current draw of 20mA each.

!

The sounders must be polarised i.e. compatible with conventional fault monitoring.

!

Ensure that the sounders are operational down to 10.5V supply voltage.

!

Connect the sounders in a straight daisy-chain manner, with no spurs or loops.

!

The recommended maximum sounder cable length is 200m.

!

Maintain strict polarity from the panel, and from one sounder to the next.

!

Remove & re-connect the factory fitted EOLR at the farthermost sounder.

One-man test

The one-man test is a test facility to aid commissioning and testing of the system, allowing

the installer to walk-test the system and trigger each detection device in turn.

!

Enter the Engineer Code followed by .

!

Press either and/or to select the zone for test - toggle on/off.

!

The selected zone/s is indicated by a rotating LED patterns on the button.

!

You now have 90s to trigger the first device, and 90s thereafter to the next device.

!

Each triggered device will pulse the sounders (but not the relay) until the test alarm

condition is clear. The panel automatically resets the detectors.

!

Press to exit the one-man test mode.

Note: The panel automatically kicks back to normal standby operation if there is 90s of

no activity or if there is a real fire condition detected on a zone not being tested.

2

1

2

1

2

1

1

1

3

Installation and Commissioning

End Of Line

Capacitor (10

µF)

EOLC

End Of Line

Resistor (10K)

EOLR

Sounder 1

Sounder 2

Sounder n

(total sounder

current not to

exceed 200mA)

Detector 1

Detector 2

Detector n

(max. 10)

SLA 12v / 1.3Ahr

Sndr Z1

Z2

-

-

-

+

+

+

Battery Fuse

Ext.Sndr Fuse

F2

F1

T1A

F500mA

Earth

L

N

230VAC

Pi

e

l

a

z

n

o

r

e

t

nI

CG1

CG2

CG3

CG4

CG5

Relay

Strobe

Mains voltage supply

from 230VAC 2A fused

outlet

CE1

CE2

R

Call Point

4

Figure 1 System Connections

Max. cable run 200m

Max. cable run 100m

Installation Instructions

Residential Fire Control Panel

Residential Fire Control Panel

1

220

Please read the following instructions carefully and

retain them in a safe place for future reference.

IX-02-142 Rev 1

Clean external surfaces with a damp cloth and mild detergent.

Do not use abrasives, solvents or polish.

Noby UK have taken every reasonable effort to ensure that the stainless steel

facia is delivered in pristine condition. Please inspect the facia prior to installing

the product as Noby UK cannot accept responsibility for any flaws or scratches

incurred whilst installing the product.

This equipment is to be installed, serviced and maintained by a suitably qualified

technical person with the requisite knowledge of electrical and fire safety

installations.

The Noby-220 is intended to be permanently connected to the 230V house wiring

via a 2A fused spur and in accordance with local wiring regulations.

Take care not to accidentally reverse the SLA battery connections during

installation. Fuse F2 will blow, but there is a remote possibility of further damage

to the electronic circuitry. Such damage is identifiable to Noby UK and is not

covered by the warranty.

Part of the internal circuitry operates at 230V and presents an electrical shock

hazard. Do not attempt to open, dismantle, repair or tamper with this equipment

without first disconnecting the mains supply voltage.

The Noby-220 incorporates fault monitoring of vital safety circuits as required by

the EN54 standard. It is important that fault indications are investigated at the

earliest by a qualified engineer.

This is Class-1 electrical equipment and must be earthed.

Unit 1F Mill Fold

Elland Road

Ripponden, HALIFAX,

West Yorkshire, HX6 4DJ

Tel:

01422 823395

Fax: 01422 823661

i n f o @ n o b y. c o . u k

w w w . n o b y. c o . u k

2

Warnings & Cautions

Technical Support (trade calls only): 01422 823661