Dwyer 460 User Manual

Page 2

DUCT AIR VELOCITY—To determine air velocity, within a confined space,

as in a duct, first find static pressure in duct as outlined above under Static

Pressure. Total pressure, or sum of velocity and static pressure, is then

found by removing supply grille probe and inserting angle connector into

duct with angled portion directed into air stream. Subtract static pressure

from total pressure to get velocity pressure, then refer to Air Velocity calcu-

lator to find air velocity. (Note: Air velocity determined will be true only for

the point of measurement—average velocity across duct may vary from this

figure.)

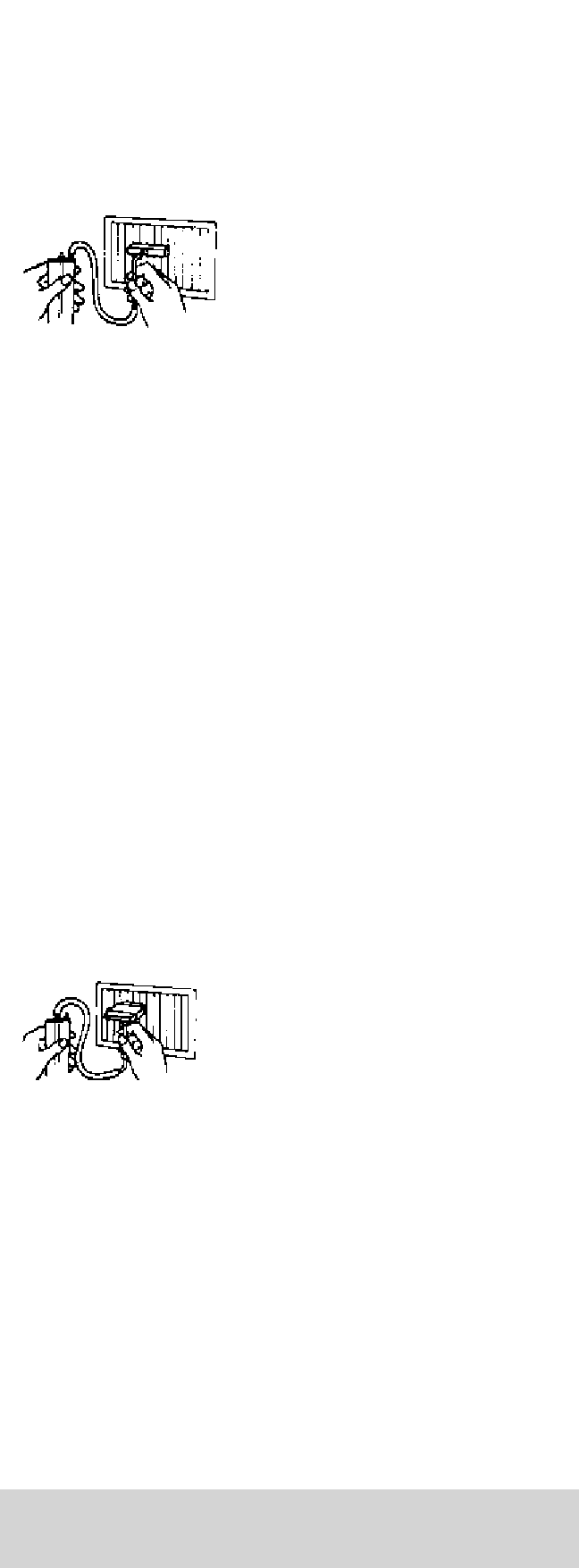

SUPPLY GRILLE VELOCITY—To measure

air velocity and determine cfm discharged from

supply grilles in air distribution systems, con-

nect supply grille probe to Air Meter and use

as indicated in sketch. Balancing a system on

a comparative basis, i.e. adjusting the controls

so the discharge velocities of all grilles are the

same, presents no problem. Using Air Meter as shown, traverse the face of

the grille. Take readings at a number of points to determine average velocity,

then make adjustment to increase or decrease flow as required. With orna-

mental diffusers it may not be practical to use supply grille probe. If so, angle

connector alone may be used, taking care to obtain measurement at same

point within diffuser face.

Calculate actual air delivered through a grille in cubic feet per minute as

follows:

Cfm = Average velocity in fpm x Effective grille area in sq. ft.

Determining effective area of most grilles, however, is difficult. Where

possible, refer to available technical data supplied by grille manufacturer.

Some manufacturers specify effective area; others give coefficient of dis-

charge; still others, a pressure loss through grille with equivalent flow in cfm.

In all cases, great care is necessary to obtain an accurate value for the cfm.

When manufacturer specifies effective area for a grille, cfm discharged

may be calculated as directed above. If manufacturer specifies coefficient

of discharge the formula becomes:

Cfm = Average velocity in fpm x Grille area in sq. ft. x Discharge coeff.

If manufacturer supplies data showing cfm corresponding to total pres-

sure behind grille face or pressure loss through grille, cfm may be deter-

mined by inserting angle connector through grille face and directing tip into

air stream. Reading obtained will be total pressure in inches of water and

cfm can be found by referring to manufacturer’s data. (Note: This technique

may be used only with grille fully open, if of the adjustable type.)

For grilles where no data is supplied or when data is invali-

dated by partial closing with dampers, approximate cfm may be found by

multiplying average velocity versus face area by a factor of .7.

RETURN GRILLE VELOCITY—To measure velocity of air entering a return

grille, connect return grille probe to Air meter and use as indicated in sketch.

Rubber tube is secured to center connector of meter. To determine volume

of air entering grille, make a careful traverse of grille face to find average

velocity. For conventional return grilles, measure actual face area, excluding

center strips, border, etc. Approximate volume

can be calculated as follows:

Cfm = Average air velocity in fpm x Face area

in sq. ft. x 95. For plain lattice grilles with a rela-

tively greater reduction in open area, the meas-

ured open area should be substituted in the

formula.

MAINTENANCE—Keep your Air Meter—

1. DRY—If moisture enters, remove bottom fitting, let moisture slowly evap-

orate. Use chemically treated pipe stem cleaner to clean indicating tube

thoroughly, removing any moisture remaining.

2. CLEAN—Use pipe stem cleaner to remove dust, lint, dirt, etc.

3. STATIC-FREE—If a static electricity charge causes ball to stick, use

chemically treated stem cleaner as in (1.) above.

4. CALIBRATED—Keep the high range calibration orifice clean and open

with nylon bristles supplied. Do not use wire, pins or drills which might en-

large opening. do not replace the 14˝ length of 3/16˝ x 5/16˝ rubber tubing

with tube of different size or length.

FR# 64-440081-00 Rev. 5

Phone: 219/879-8000 Fax: 219/872-9057

www.dwyer-inst.com

DWYER INSTRUMENTS, INC.

P.O. Box 373 • MICHIGAN CITY, IN 46360 U.S.A.