Dwyer instruments, inc – Dwyer RRT3 User Manual

Page 2

Mechanical Installation

1. For mounting, select a clean, dry location, free from extreme temperatures.

2. Cut a 3-7/32˝ (82 mm) diameter hole in the panel for the thermometer.

3. Prior to inserting the thermometer into the panel, remove the mounting bracket.

4. Insert the thermometer into the panel cutout from the front.

5. Place the U-bracket on the back of the thermometer (make sure the screws are

aligned with the holes in the mounting bracket).

6. Secure the bracket into place by tightening the nuts until the bracket is tight against

the panel.

7. The probe should be mounted so the bulb is fully immersed in the media and where

the media temperature will be evenly distributed.

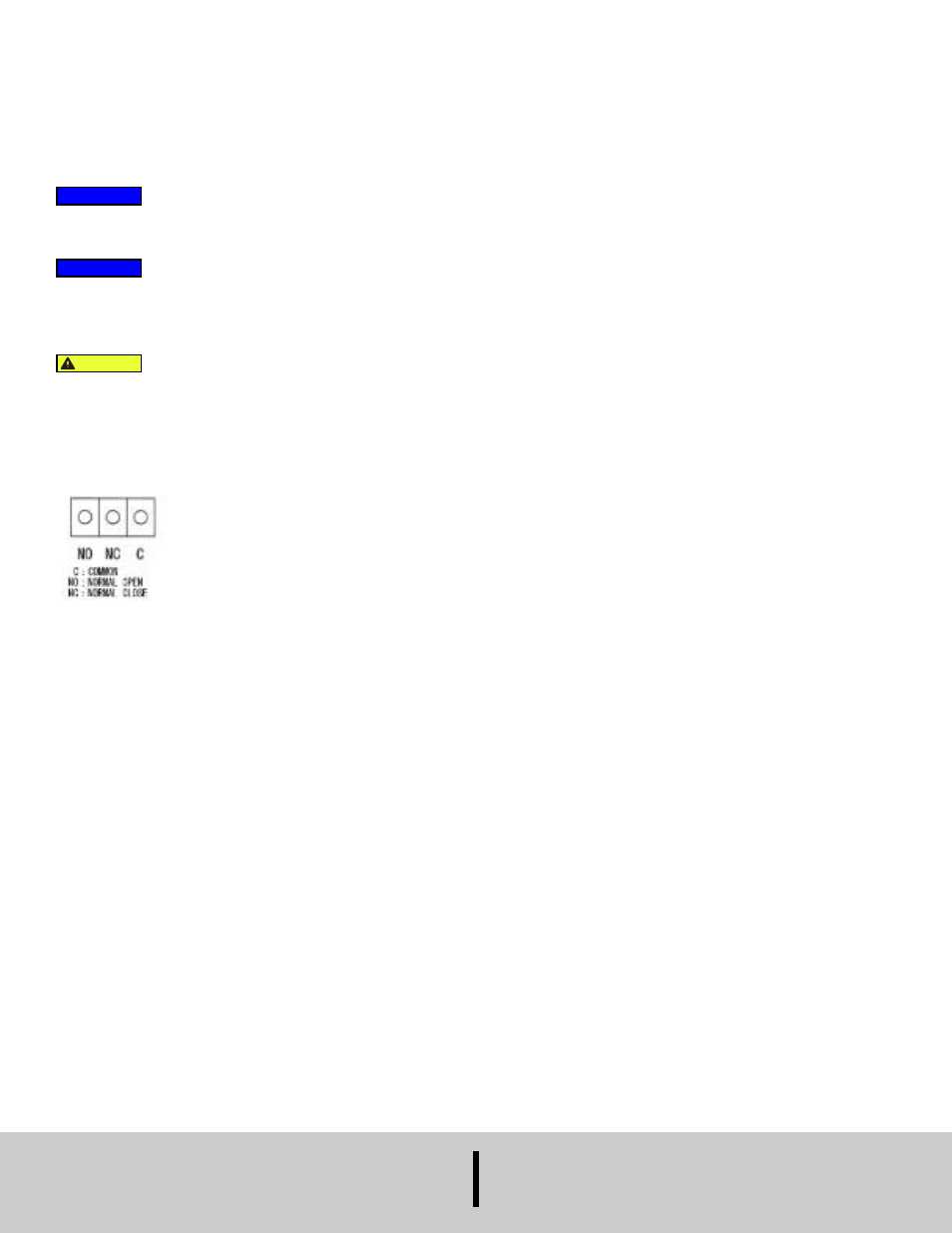

Electrical Connections

1. Connections for the switch are made by three connections. The quick connect

terminals are labeled N.O., N.C., and COM. N.O. is the normally open terminal,

COM is the common terminal, and N.C. is the normally closed terminal.

2. For NC (normally closed) operation, make switch connections using terminals COM

and N.C.

3. For NO (normally open) operation, make switch connections using terminals COM

and N.O.

Set Point Operation

The switch set point is fully adjustable across the entire range of the unit. The unit is

equipped with internal stops at the minimum and maximum values of a specified

range.

Adjust the set point by rotating the black knob on the front of the dial case to the

desired temperature setting.

MAINTENANCE/REPAIR

Upon final installation of the Series RRT3, no routine maintenance is required. The

Series RRT3 is not field serviceable and should be returned if repair is needed. Field

repair should not be attempted and may void warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping the

product back for repair. Be sure to include a brief description of the problem plus any

additional application notes.

©Copyright 2012 Dwyer Instruments, Inc.

Printed in U.S.A. 3/12

FR# R5-443930-00

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A.

Fax: 219/872-9057

e-mail: [email protected]

Do not exceed the specified electrical ratings shown on the unit.

Permanent damage, not covered by the warranty, will result.

CAUTION

If panel thickness exceeds 13/64˝ (5 mm), the bracket must be

shortened accordingly.

NOTICE

Since temperature effects along the capillary are compensated

for, the capillary should not be located close to other

temperature sources. Take care in arranging the steel capillary to avoid sharp

bends that might kink internal capillary tube.

NOTICE