Installing replacement cable, Special applications, Cutter selection – BrassCraft 20 Series User Manual

Page 5

TO REMOVE DRUM

• The release hook is situated immediately behind the drum. Pull

hook upward and pull drum forward to remove it from the

spindle. (see Fig. 3)

• TO REPLACE the drum, reverse the steps above.

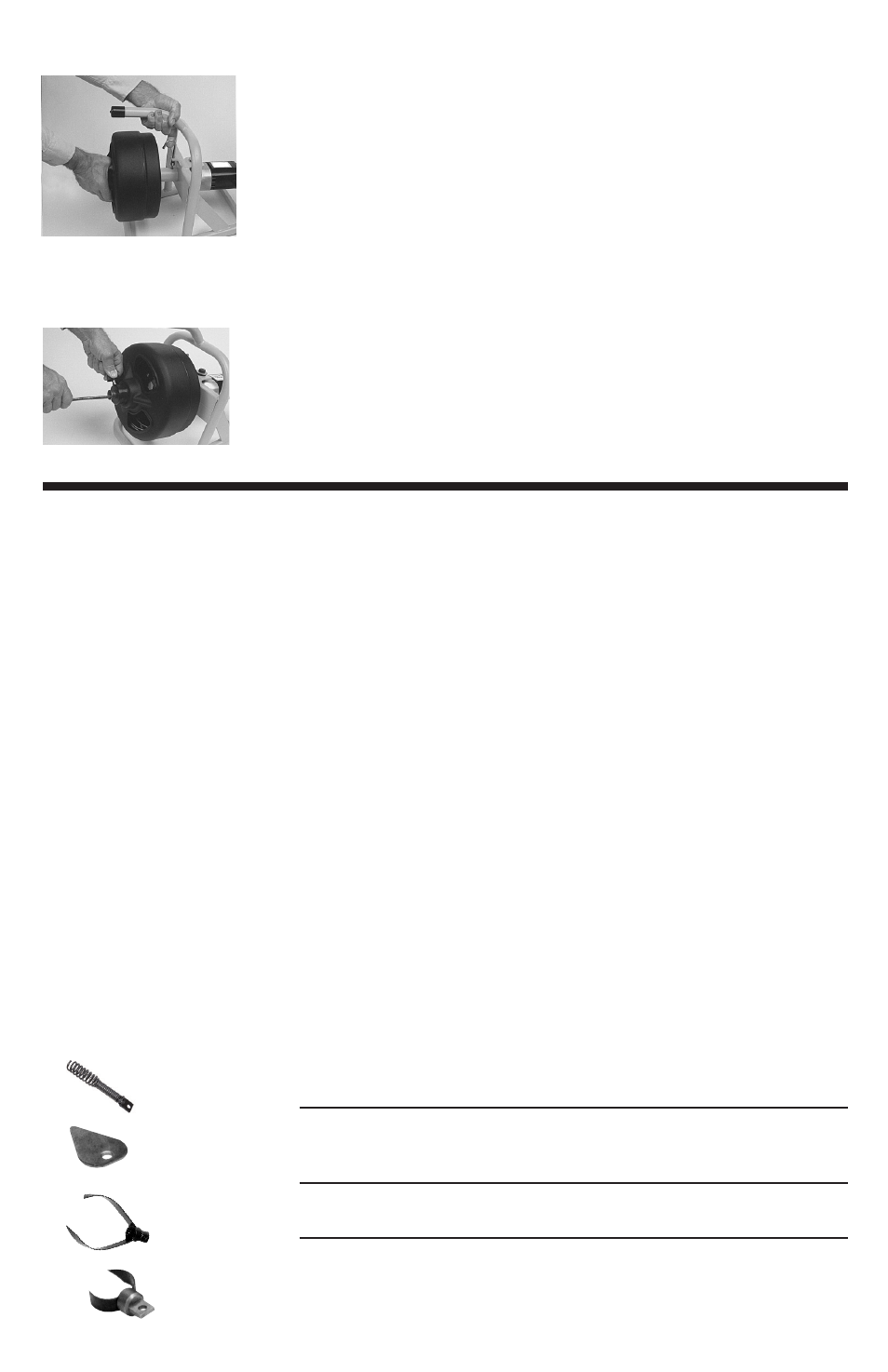

INSTALLING

REPLACEMENT CABLE

• Loosen thumbscrew and remove the existing cable from

the machine.

• Uncoil the new cable completely. Carefully insert the cable into

the drum and continue doing so until installation is complete.

• Finally, tighten the thumbscrew. (see Fig. 4)

Figure 3

Figure 4

SPECIAL

APPLICATIONS

Reverse Operation

Running this machine in reverse should only be done if the cable

becomes blocked and only for a few seconds, enough to free the

end of the cable. If the cable gets caught on an obstruction,

immediately release the trigger and take your foot off the foot pedal to

allow the machine to come to a complete stop. Fully tighten the

thumbscrew and turn the drill switch to the (REV) position and depress

the foot pedal. Grasp the cable with a gloved hand and pull it while

jogging the trigger. When the cable is dislodged, place the drill motor

switch in the forward (FOR) position, loosen the thumbscrew, and

follow normal operating procedure.

Lubrication

Grease all exposed and moving parts.

Storage

The machine must be kept in a dry, safe place, out of the reach

of children.

Cables

The metal cable should be thoroughly cleaned with water to prevent

unpleasant odors and the damaging effects of drain cleaning

compounds.

CUTTER SELECTION

Straight Boring Head

For use when exploring and breaking up blockages or returning

samples to the surface to determine the correct tool to use.

Spear-Head

For exploring and breaking up stoppages.

Side Cutter

For use in cleaning pipes of various material clinging to pipe walls.

Grease Cutter

For cleaning any stoppages, rags, sticks, grease, etc –

the all rounder.