Seametrics M-Series User Manual

Dis con tin ued

General Information

M-Series meters use the multi-jet principle, which has

been an internationally-accepted standard for many

years. This type of meter is known for its wide range,

simplicity, and accuracy in low-quality water. The im-

peller is centered in a ring of jets, with inlet jets on one

level and outlet jets on another. A gear train drives the

register totalizer dials. For pulse output, one of the

dials is replaced by a magnet, which is detected by an

encapsulated sensor threaded into the outside of the

lens. Pulse rate is determined by the number of poles

on the magnet and the dial placement. Changing the

pulse rate requires no special tools and can be done in

the field.

Mechanically, all M-Series meters are the same. The

difference between ME, MR, and MT meters is in the

sensor. ME meters use a solid-state, long-lasting Hall-

effect sensor, which requires power. It is suited for use

with SeaMetrics controls and metering pumps (LMI for

instance) which have sensor power. MR meters use a

two-wire reed switch. They provide a dry contact clo-

sure and do not require power. MT meters totalize only

and do not have a sensor.

Features

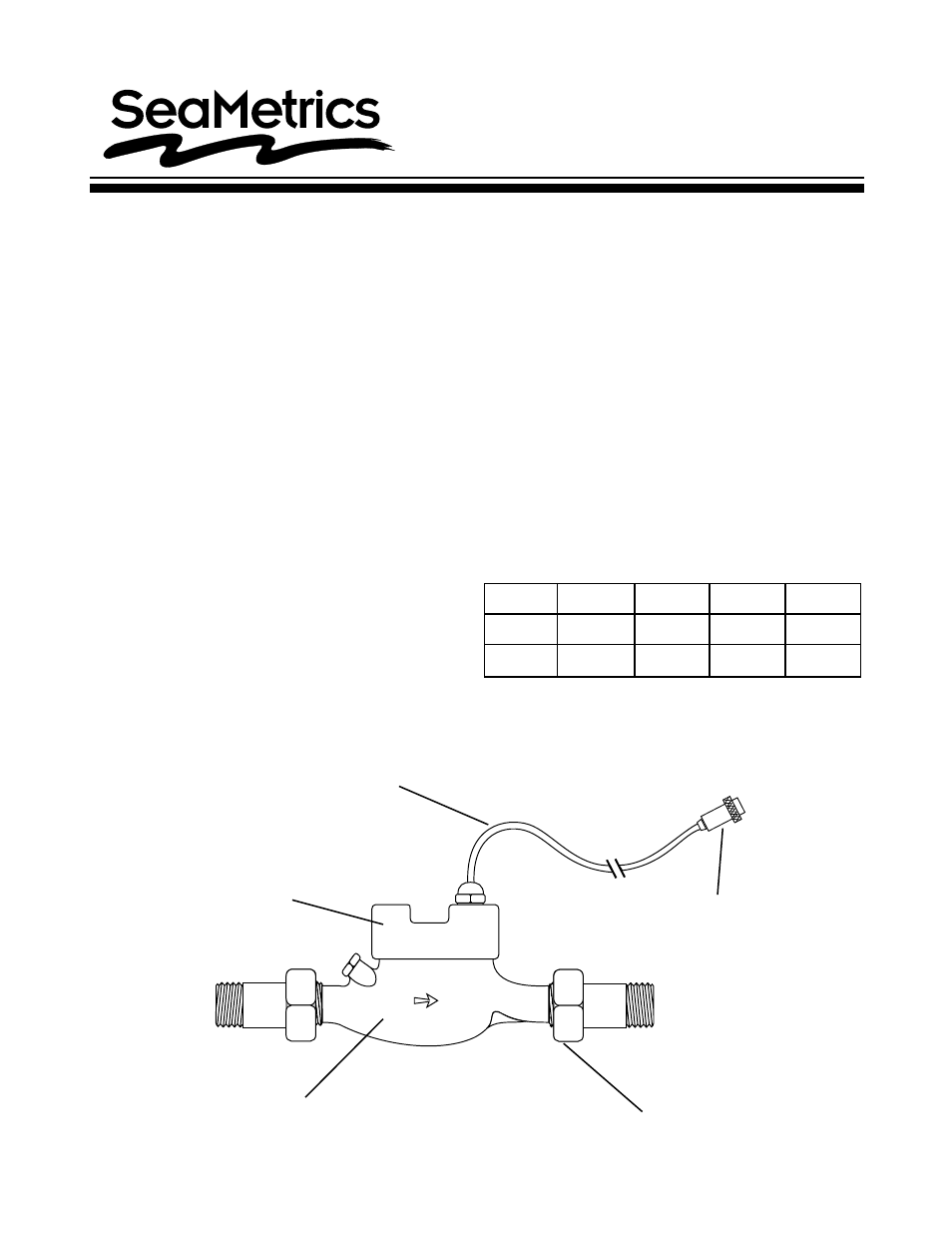

M-Series Pulse Meter

Instructions

Specifications

Materials

Case

Cast bronze

Internals

Engineered thermoplastic

Magnet

Ceramic permanent

Temperature

105

°

F, 40

°

C

Max. Pressure

150 PSI operating

Accuracy

1-1/2% of reading

Sensor

ME

Hall-effect device

MR

Reed switch

Max. Current

ME

20 mA

MR

50 mA

Max. Voltage

ME

24 VDC

MR

24 VDC or 24 VAC

Sensor Power (ME)

Minimum 6 mA at 12 VDC

Cable Length

12 ft. standard, 2,000 ft. max.

Flow Rates (GPM):

LT-10613A

Page 1 of 4

3/4"

1"

1-1/2" 2"

Minimum 0.25 0.30 0.50 1.00

Maximum 20 50 100 130

Either ME or MR sensor

threads into lens without

removing top

Top removes with no

special tools

Cast bronze body-

meets AWWA

specifications

Union end couplings

for easy service

Connector for metering pump or

SeaMetrics control standard

on ME, optional on MR

DIS

CON

TIN

UED