Ar ch ive d – Seametrics EX80 Series v.2 User Manual

Page 11

oPEration & maintEnancE

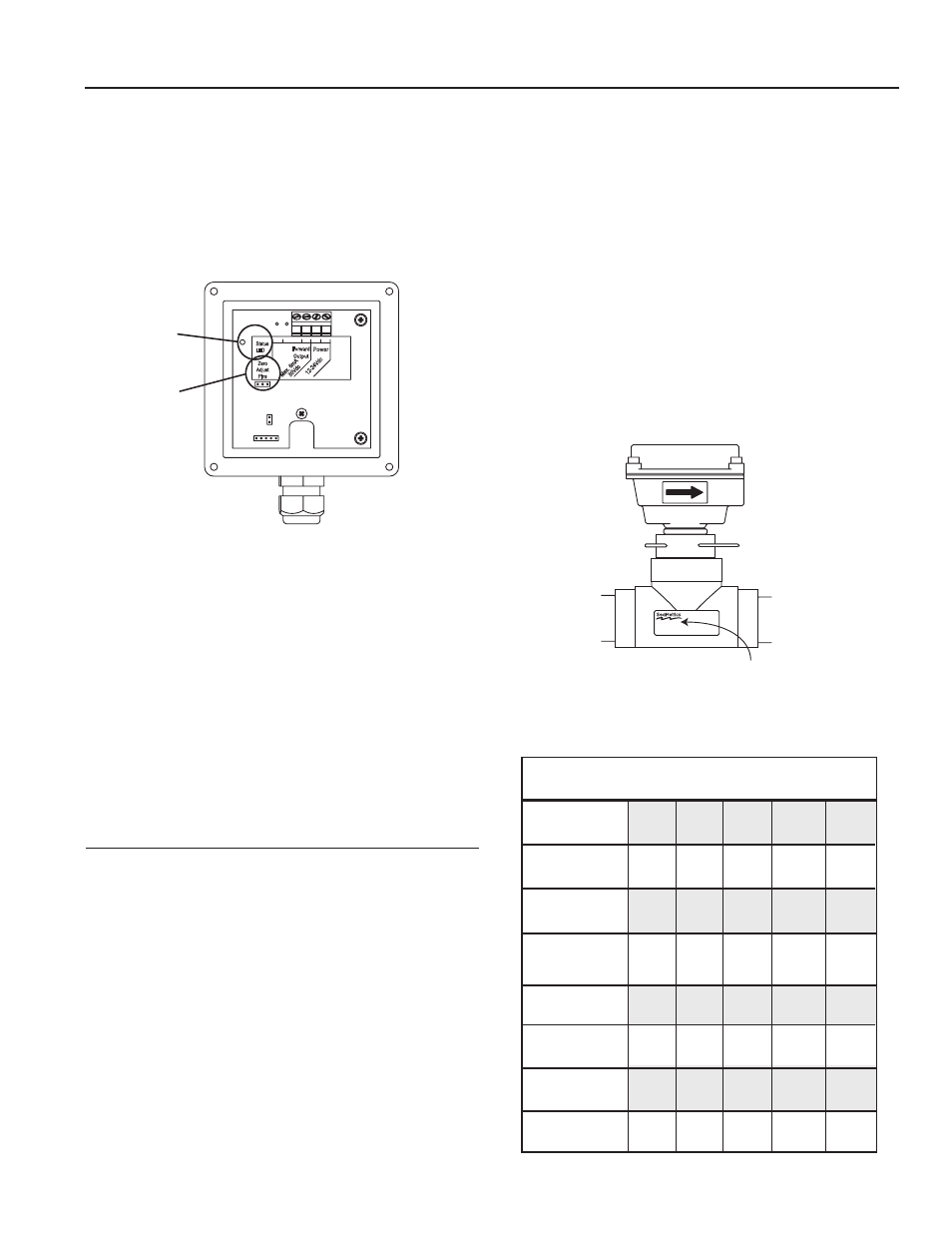

Zero adjustment. When the EX81 or 82 is powered up

and there is no flow, there should be no output pulses (or,

if connected to the FT420, flow rate should read “0”). If

there are pulses it may be necessary to adjust the flow

meter under no-flow conditions after it has been installed.

This should only be done if the indicated flow is low, near

the lower cutoff.

To perform the adjustment, after determining that there is

a full pipe with no flow, short between the two pins marked

“Zero Adjust”. A red LED light will come on for approxi-

mately 50 seconds and then go out. The zero adjustment

is completed.

minimum Flow.

As with any other flow sensor, there is a rate

below which the EX80-series sensor cannot read. Check the

flow rate table below for the minimum flow rate detectable

by the sensor for a given pipe size.

Presence of Flow indication.

To assist in troubleshooting,

the “Status LED” has two blinking modes in normal

operation. When there is no flow detectable by the meter

(below minimum threshold) the LED blinks ever y 8.0

seconds. When there is detectable flow, the same indicator

blinks every 3.0 seconds.

Filtering.

The software of the EX80-series sensor filters

out electrical noise and averages sudden variations in the

flow to smooth the output. It takes a matter of seconds for

the flow sensor to get up to full output when it is powered

up or when flow begins.

calibration (“K-factor”). The K-factor represents the actual

number of pulses per gallon the meter produces during a

flow test. This number can be entered into your electronic

control to make it read properly. If the EX80 Series meter

is ordered with a tee fitting, it is factory-calibrated in the

fitting and the K-factor is indicated on the side of the fitting

(see diagram).

Find your K-Factor Here

Page 9

1” 1-1/2” 2” 3” 4” 6” 8” 10”

• Min .50 1.1 2 4.5 8 18 31 49

•

Max 50 110 196 440 783 1763 3133 4895

FloW ratE (gPm)

30

Vdc

Max. 6m

A

- +

- +

12-24

Vd

c

3

4

5

6

2

1

Power

Forward

Output

Status

LED

Zero

Adjust

Pins

Zero

adjust

Pins

Electrode coating.

Grease or other adhering, non-

conductive materials can stop flow detection if the

electrodes become heavily coated. To clean the electrodes,

remove the sensor from the pipe and gently scrub the

electrodes (three silver bumps) on the reading face of the

flow sensor. A mild soap (dishwashing liquid for example)

can be used to aid the cleaning process.

10031295

EF81T-P200

K:158.42

If the EX80 Series meter is ordered with a saddle or wel-

dolet fitting, find your K-factor in the chart below.

3” 4” 6” 8”

10”

K-FactorS SaDDlES & WElDolEtS

70.397

78.748

62.385

70.397

76.371

78.371

70.672

57.376

40.985

45.360

36.626

40.985

43.552

44.638

41.517

37.320

6.674

7.322

6.173

6.674

7.230

7.500

6.674

6.197

10.497

11.495

9.642

10.497

11.201

11.622

10.445

9.503

18.130

20.084

16.510

18.130

19.513

20.223

17.778

16.915

Status

lED

PVc/Steel

Sch. 40

PVc/Steel

Sch. 80

Stainless

Steel (10S)

Stainless

Steel (40S)

copper tubing

(type l)

copper tubing

(type K)

brass Pipe

Duct. iron

(class 52)

AR

CH

IVE

D

(Includes Dates 6/28/05 to 10/06)