Ar ch ive d – Seametrics EX100-200 Series v.2 User Manual

Page 4

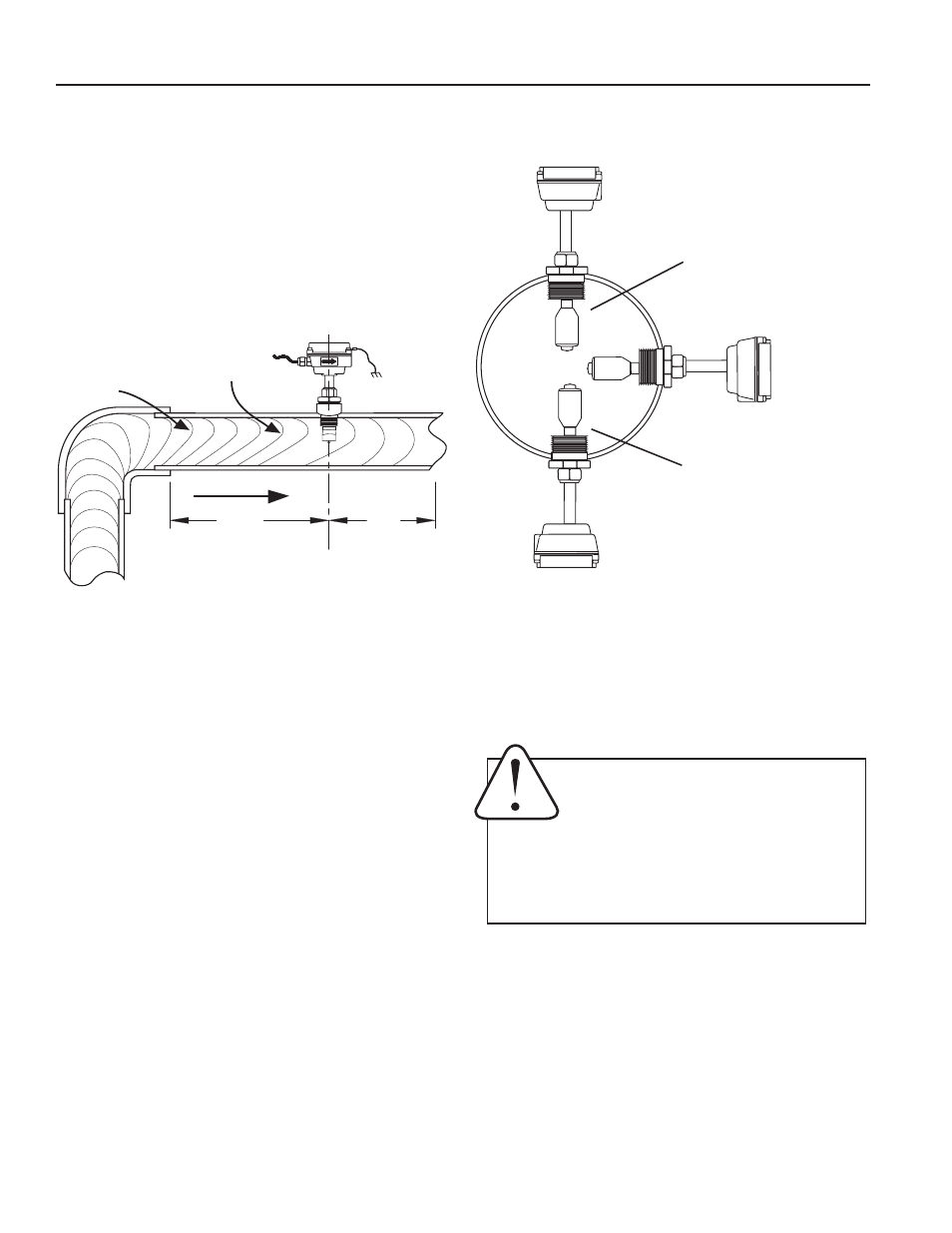

Piping. For best results, the EX sensor should be in-

stalled with at least ten diameters of straight pipe

upstream and five downstream. Certain extreme situations

such as partially-opened valves are particularly difficult and

may require more straight diameters upstream.

Immersion. The 100/200 Series standard sensors are

not designed for continuous underwater operation. If this

is a possibility, as in a flooded vault, a unit modified for

immersion should be specified (Option -40).

Page 2

Caution: These flow sensors are not

recommended for installation down-

stream of the boiler feedwater pump

where installation fault may expose the

flow sensor to boiler pressure and temperature.

Maximum recommended temperature is 130°F

(Plastic), 200°F (Metal).

INSTALLATION

DISTORTED FLOWS

Distorted

Flow Profile

FLOW

10X

Diameter Minimum

5X

Diameter

Minimum

POSITIONING ThE METER

Horizontal is the preferred installation orientation, since it

improves low-flow performance and avoids problems with

trapped air. Bottom, top, and vertical pipe installations are

all acceptable if required by the piping layout.

Fair

(Unacceptable position

if air is present)

best

Position

Fair

(Unacceptable position if

fluid contains sediment)

Faster Flow

Causes Meter

To Read high

AR

CH

IVE

D

(Includes Dates 5/05 to 9/06)