Seametrics AG2000-Series User Manual

Page 2

Page 2

INSTALLATION

Tamper-Evident Seal.

The battery-powered AG2000 has a seal

wire to protect against unauthorized access. The seal can be

broken to change units of measure, replace the battery pack, or

to field-install a power/output cable (see page 4). CAUTION: If

water usage regulation is in effect, only a person authorized by

your regulatory agency should break the seal wire, and replace

it when finished.

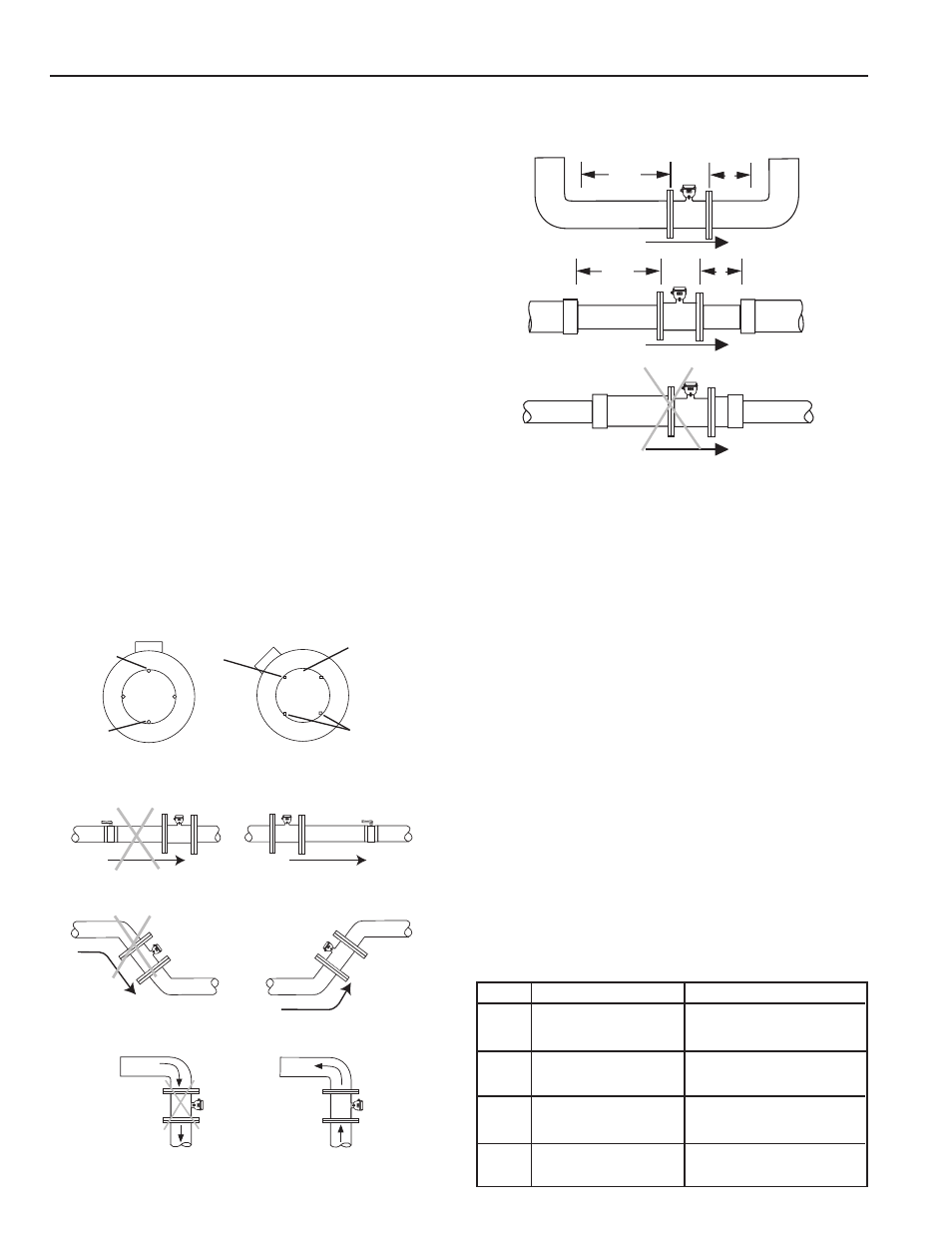

Positioning the Meter.

These meters can be installed horizontally,

vertically, and in any radial position. If sludge accumulation

is possible, vertical or horizontal placement with the register

at a 45˚ angle is recommended. Using a check valve on the

upstream side of the meter, and/or an air vent (vacuum relief

valve) in the same, unobstructed run of pipe as the meter, is

required in any installation where the meter may be exposed

to suction when the system is not in normal operation. Suction

can cause damage to the liner. Liner damage caused by

suction, without the use of a check valve and/or air vent, may

void the warranty.

Full Pipe Recommendations

. All magmeters require a method

for determining that the pipe is empty, to prevent false reading.

This meter is designed to go to zero reading if one or more

electrodes is exposed. For highest accuracy, install the meter so

that the pipe will be full when there is flow. If air bubbles may be

present in the pipe, rotate the meter by one flange hole to position

the control housing at a 45˚ angle. See mounting diagrams below.

Straight Pipe Recommendations

. See the diagrams below

for manufacturers’ recommendations. Local regulations may

vary, confirm before installing to assure compliance.

2X

1X

2X

1X

pipe size

pipe size

pipe size

pipe size

Elbows

Reduced Pipe

(not recommended)

Expanded Pipe

FLOW RANGE

Fittings and Flanges

. The AG2000 flanges have standard ANSI

150 lb. drilling, and should match up with any other ANSI 150 lb.

flange. IMPORTANT: Piping protruding beyond welded-on flange

faces may damage meter sealing surfaces.

Temperature

. These flow sensors are recommended for operating

temperatures of 10˚ to 130˚ F (-12˚ to 54˚ C) and non-operating

temperatures of -40˚ to 158˚ F (-40˚ to 70˚ C).

Calibration

. The AG2000 is factory calibrated and cannot be

recalibrated in the field.

Protecting the Meter.

A weather guard is recommended

(Seametrics part #31388) for environmental protection.

Conductivity.

The AG2000 requires media with >20 microSiemens/

cm of conductivity.

Chemigation Applications.

Magmeters in chemigation ap-

plications must be placed either upstream of the chemical

injection line, or far enough downstream for complete mix-

ing to occur before the solution reaches the meter. Proper

placement prevents spikes and drops in readings that result

when fluids of different conductivity pass through the meter.

(For more information, refer to the technical bulletin on the

Seametrics website Downloads page.)

Minimum Maximum

4”

12 gal/min

1,000 gal/min

(.75 liter/sec)

(63 liter/sec)

6”

32 gal/min

2,400 gal/min

(2 liter/sec)

(151 liter/sec)

8”

60 gal/min

4,400 gal/min

(4 liter/sec)

(278 liter/sec)

10”

95 gal/min

7,000 gal/min

(6 liter/sec)

(442 liter/sec)

Possible Problem: Air pockets,

accuracy loss, empty pipe reading

Better Installation: Keeps pipe full

at sensor for accuracy

Possible Problem: Air can be

trapped, loss of accuracy

Better Installation: Allows air

to bleed off, higher accuracy

Not Recommended: Vertical

downflow, open discharge

Possible Problem:

Air bubbles and sediment on the

electrodes can affect accuracy.

Better Installation:

Improved accuracy results from

unimpeded electrodes.

Electrode

moved from

top by rotating

meter

Intermittent air

bubbles

miss electrode

Intermittent air

bubbles

pass over

electrode

Possible

sediment

build-up

Electrodes free

from sediment

build-up

Better Installation: Vertical

upflow with full pipe

Note: See Technical Bulletin ‘Piping Configurations for AG2000 Magme-

ters’ at www.seametrics.com for additional configuration information.