Seametrics TX800-Series User Manual

Page 9

Sensor Replacement.

It is very unusual for a sensor to re-

quire replacement in normal use. The primary cause of sensor

failure is overvoltage (inadvertent connection of line voltage,

for example) or incorrect polarity on hookup. The sensor is

replaced by removing the strain relief, then threading out

the sensor retainer plug. Remove the entire sensor capsule

by pulling on the cable. The new sensor capsule can then be

installed, orientation is not critical. Replace the retainer plug,

and then replace and tighten the strain relief.

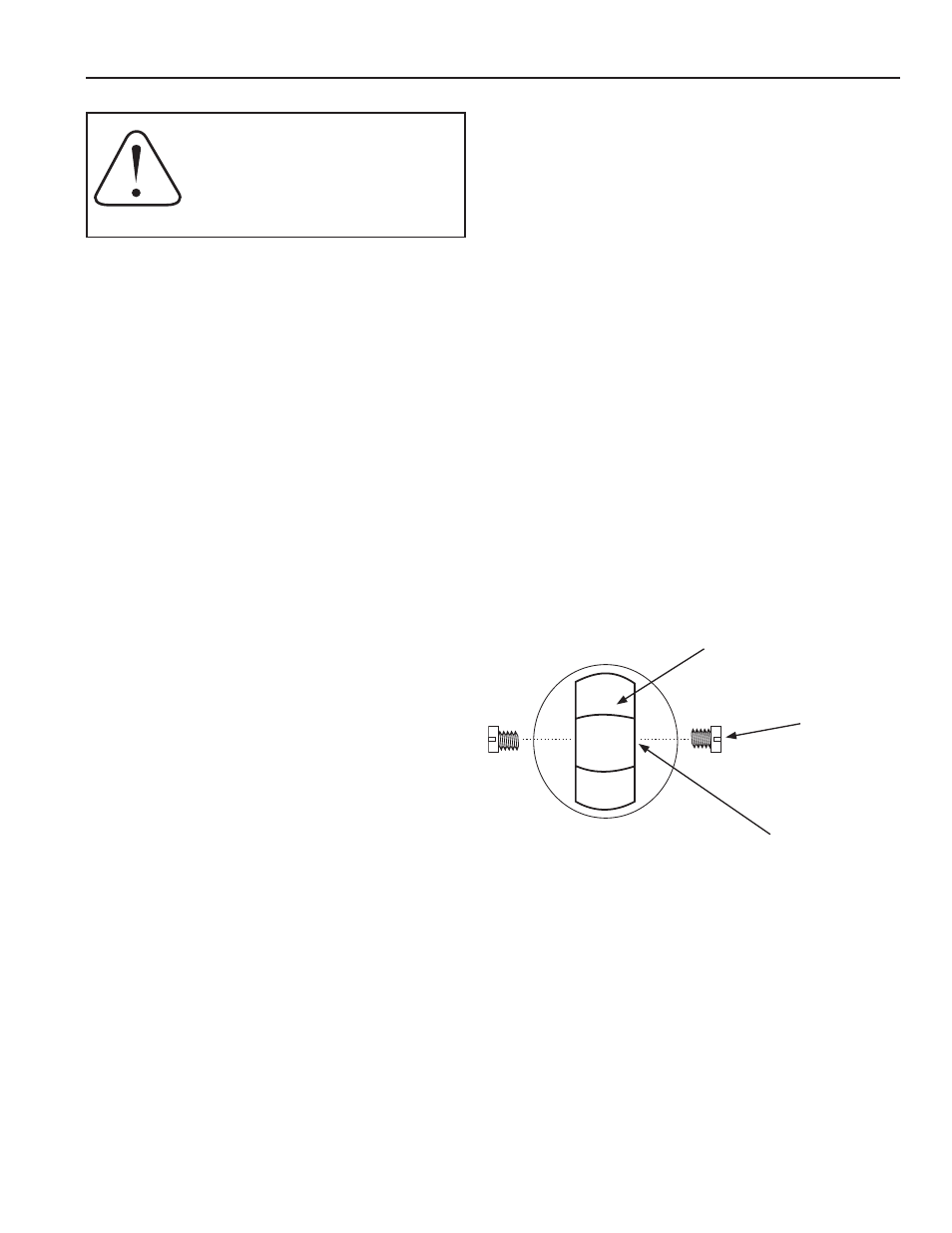

Rotor Replacement.

It is unusual for a rotor to require

replacement due to damage sustained in normal service.

More commonly, the meter is dropped while it is out of the

pipe. Another reason for rotor replacement is shaft wear

after long service. Rotors are easily field-replaced.

To install a rotor, follow these steps:

1. Unscrew the threaded bearing housings to expose

the shaft ends. If bearings are being replaced,

back them completely out.

2. Remove the rotor. Put the new rotor in its place.

3. Thread in one bearing housing part way, then the

other. Take care to start the end of the shaft into

the bearing hole before tightening further.

4. Screw in bearing housings until they bottom.

Note: Do not use excessive force.

5. Check for free spin. Blowing lightly on the rotor

should result in it spinning rapidly and coasting to a

smooth stop.

Caution:

Never remove the u-clip retainer

when the pipe is under pressure. Always

remove pressure from the pipe before at-

tempting to remove the meter. Removal

under pressure may result in damage or

serious injury.

MAINTENANCE

Page 7

Signal Troubleshooting.

The flow sensor has only one moving

part, the rotor. If this is turning properly and there is no signal,

the magnetic sensor is not operating properly. To check the

signal, apply 12 Vdc regulated* power to the red (+) and black

(-) leads. Set a multimeter to voltage reading. Put the positive

multimeter lead on the red wire and the negative lead on the

white wire. Slowly turn the rotor. Voltage reading should swing

between +12 Volts and 0 Volts as the rotor turns. If it does

not, the solid-state magnetic sensor is not working properly.

Checking for continuity is not a useful test of these sensors.

*NOTE: An unregulated power supply can exceed max voltage of

micro powered sensor (gray cable) and damage sensor.

Rotor Replacement

Shaft

Turbine Rotor

Bearing

Housing