Instructions for using the flow test kit, Typical tests – Lake Monitors WTA Hydraulic System Analyzer User Manual

Page 3

Model No.

Flow range

Max. Pressure

Temperature range

WTA-32

1.3 – 32 GPM

5 – 120 lpm

6000 psi

420 bar

50 – 180˚F

10 – 80˚C

WTA-50

2– 48 GPM

5 – 180 lpm

6000 psi

420 bar

50 – 180˚F

10 – 80˚C

Connections

By flexible hoses

(2' – 3' recommended length)

Inlet Port: #16 SAE

Outlet Port: #12 SAE

Adapters are available to suit most applications. Consult sales office for details.

Connect the analyzer into the hydraulic system as required using two 2' – 3' long hoses. Ensure

that the flow you wish to measure is passing through the test analyizer in the direction of the

double-arrows on the flow indicator dial. Flow is allowed in the direction of the single arrow, but

this flow will not be measured.

Instructions for using the Flow Test Kit:

1. Open loading valve by rotating counter-clockwise.

2. Start pump momentarily to ensure that oil flows freely through the hydraulic system, then

run pump at maximum speed. Do not change pump speed while turning the loading valve.

3. Slowly close the loading valve to develop the desired pressure. Run the machine until nor-

mal operating temperature is reached i.e. typically 45 - 60°C (110 - 140°F).

4. Open the loading valve to read the flow at minimum pressure.

5. Close loading valve slowly to increase pressure and note reduction of flow as the pressure

is increased to maximum pump pressure to determine pump condition.

10

20

30

40

50

60

70

80

50

75

100

125

150

175

°

F

°

C

10

20

30

40

50

60

70

80

50

75

100

125

150

175

°

F

°

C

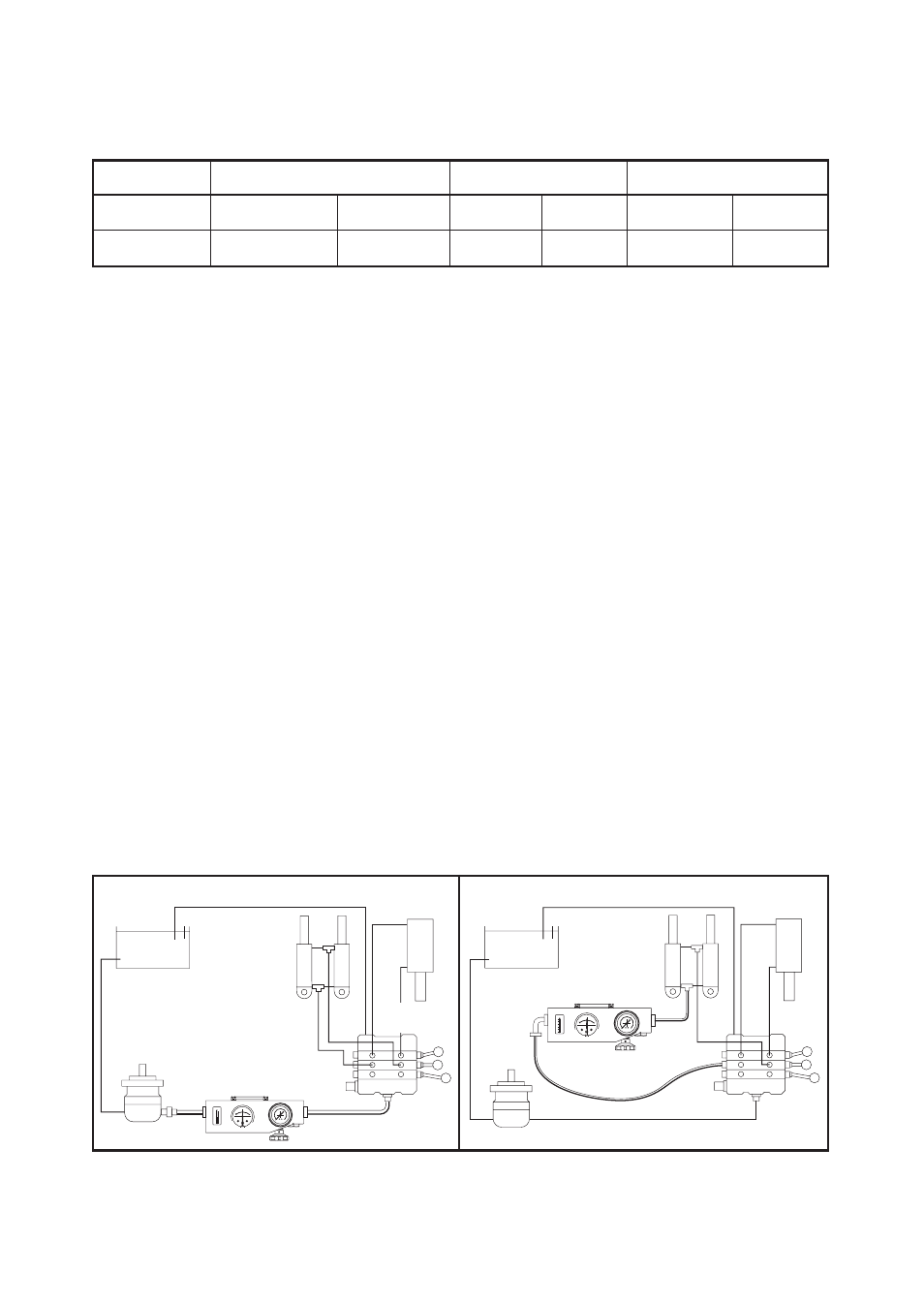

Cylinder

Cylinder

Tank

RFIK

RFIK

Tank

Pump

Pump

Directional

Valve

Test Hose

Relief

Valve

Relief

Valve

Pump Test

Overall System Test

Typical Tests