Initial start up – Detcon FP-524D Quick Start Guide User Manual

Page 2

www.detcon.com

713.559.9200

FP-524D Quick Start Guide

April 23, 2014 • Document #4462 • Revision 1.1

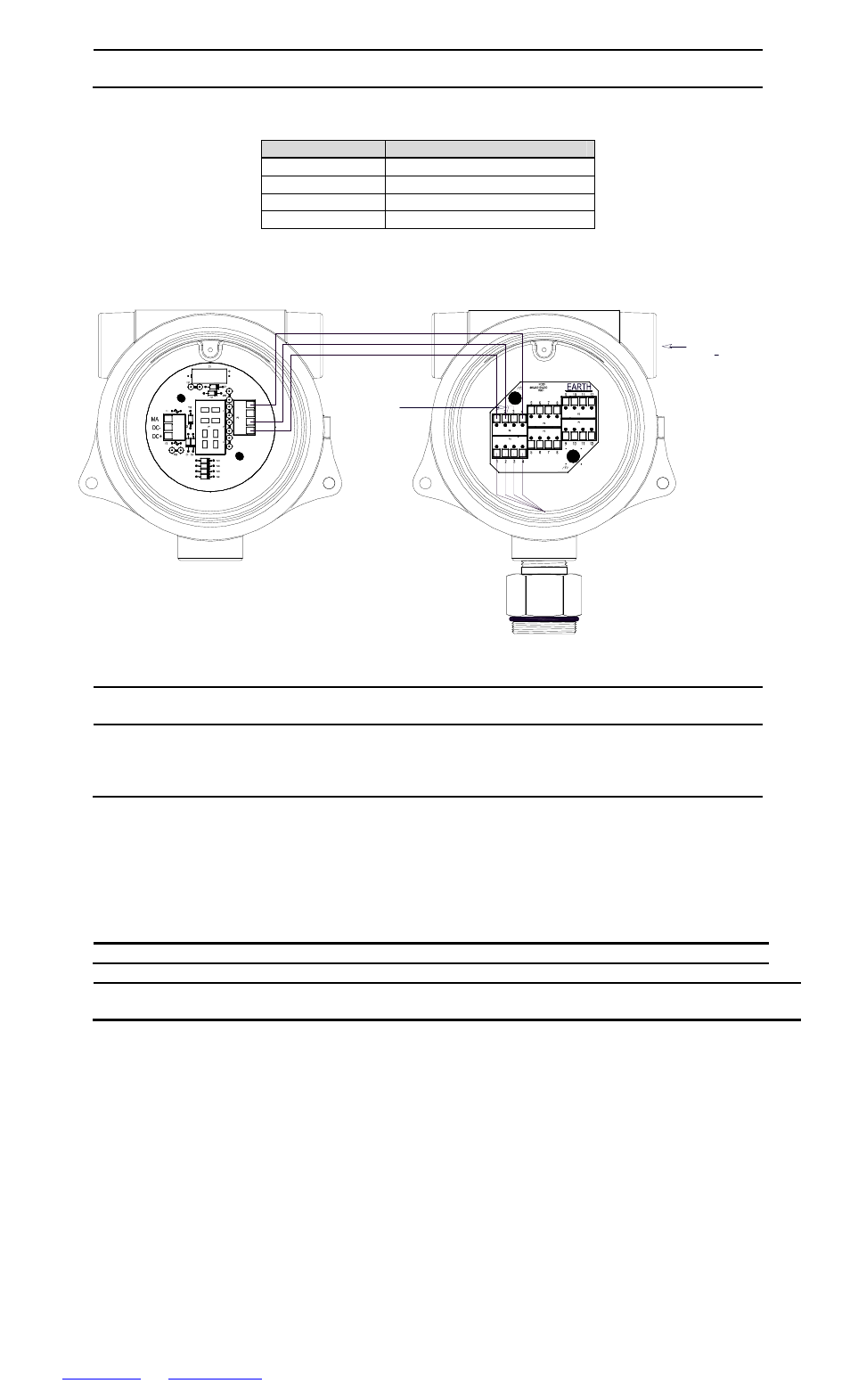

wiring diagram in Figure 2. There is a limit 0.5-ohm maximum resistance drop per wire over the

separation distance.

Table 1 FP-524D Remote Sensor Maximum Separation

AWG

Maximum Separation (feet)

20

50

18

75

16

125

14

175

Plug unused port

with

3

4

" NPT plug

Measure Bridge Voltage

From White (1) to Blue (4)

Target Voltage is 2.7V

Remote Sensor

FP-524D-RS

Remote Transmitter

FP-524D-RT

Install

Jumper

Blue

Ye

llo

w

Black

White

Bl

ue

Bl

ac

k

W

hi

te

Bl

ue

Bl

ac

k

W

hi

te

Figure 2 FP-524D Remote Sensor Wiring Diagram

NOTE

A jumper is required on the remote sensor connector board. Failure to install this jumper will

cause a sensor fault condition.

NOTE

For remote-mounted sensors, different lengths of cables will have varying amounts of resistance,

which will shift the sensor bridge voltage. Therefore, the bridge voltage must be adjusted after

initial power up. This adjustment is only required after initial installation and will not be

necessary thereafter (except in case of replacement of the plug-in sensor).

Initial Start Up

1. Upon completion of all mechanical mounting and termination of all field wiring, apply system power in the range

of 12-28VDC (24VDC typical) and observe the following normal conditions:

a.

FP-524D display reads “0” and no fault messages are flashing.

b. A temporary upscale reading may occur as the sensor heats up. This upscale reading will decrease to 0%

within 1-2 minutes of power-up, assuming there is no gas in the area of the sensor.

NOTE

The 4-20mA signal is held constant at 4mA for the first 2 minutes after power-up.

2. After a warm up period of 1 hour, check the sensor to verify sensitivity to combustible gas.

NOTE

Do not use calibration gases in nitrogen background gas mixtures. This will cause significant reading

inaccuracies.

a.

Attach the calibration adapter to the threaded sensor housing.

b. Apply the test gas at a controlled flow rate of 200–500 cc/min (200 cc/min is the recommended flow).

c.

Allow 1-2 minutes for the reading to stabilize.

d. Observe that the display increases to a level near that of the applied calibration gas value during the 1-2

minutes.

e.

Remove test gas and observe that the display decreases to zero.

3. Initial operational tests are complete. Detcon FP-524D combustible gas sensors are factory-calibrated prior to

shipment and should not require significant adjustment at start-up. However, it is recommended that a complete

calibration test and adjustment is performed 16 to 24 hours after power-up.