DeFelsko PosiTest AT v.1.0 User Manual

Page 2

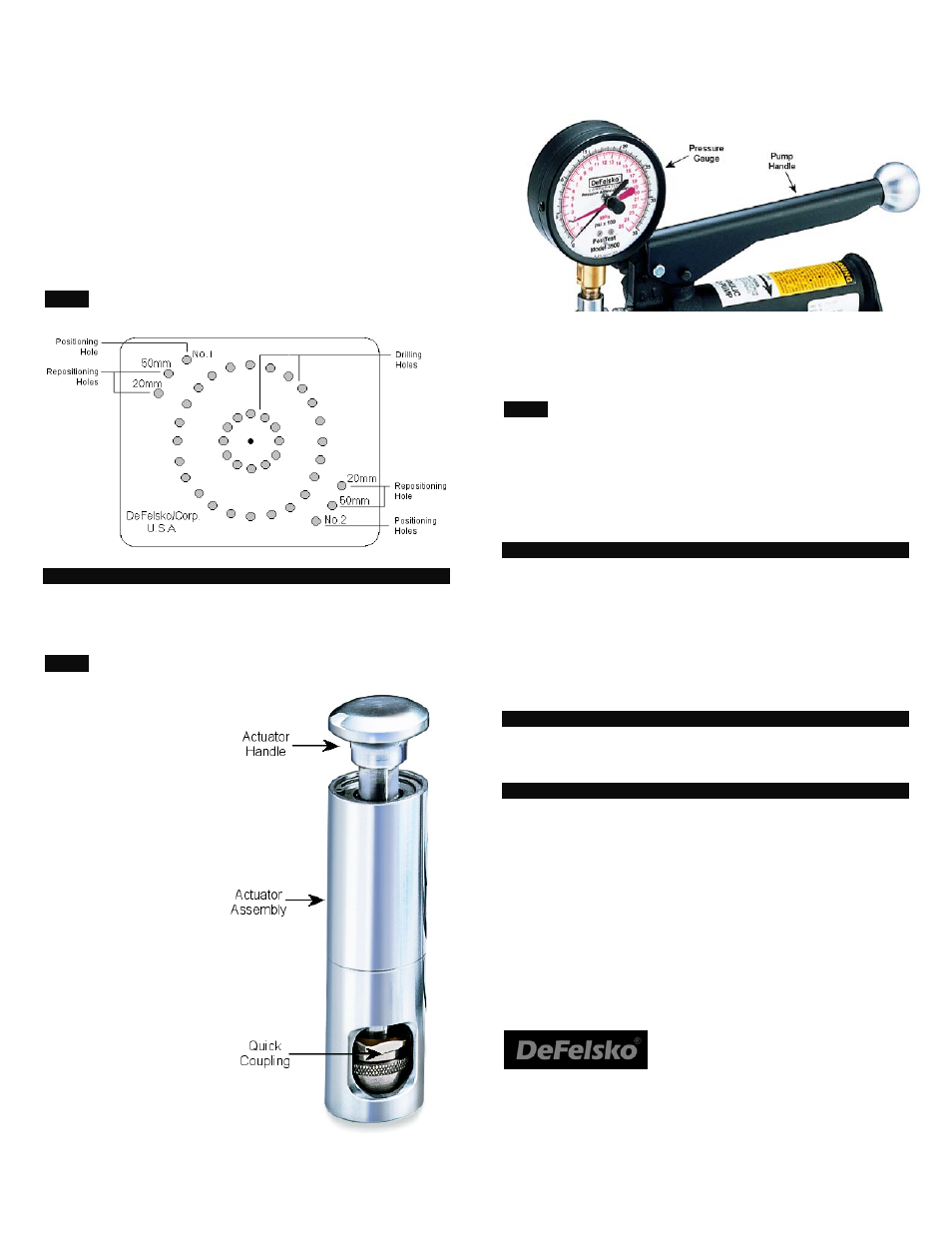

4. Reposition the template and insert the two attached pins

through the template holes marked No.1 and No.2 and into

the two drilled positioning holes.

5. The template is now positioned to drill either the 20mm or

50mm circle of holes (depending on dolly size) into the coating.

6. After all holes have been drilled into the coating for the

chosen circle size, remove the template and clean debris

from the surface.

7. To complete the drilling process and remove all material

between existing holes, place the template back onto the

surface but rotate so the drilled positioning holes line up with

the template repositioning holes labeled 20mm or 50mm, as

appropriate. Replace positioning pins and repeat steps 5 & 6.

Note:

Make sure all holes for the chosen circle size are drilled

completely through the coating to the substrate surface.

Pull Testing

1. Ensure the pressure relief valve on the pump is completely

open

2. Turn the red “drag” indicator on the pressure gauge to zero.

Note:

If the black indicator will not return to zero, check to be

sure that pressure has been completely relieved from the

system.

3. Push the actuator

handle completely

down into the actuator

assembly.

4. Place the actuator

assembly over the

dolly head and attach

the quick coupling to

the dolly by reaching

through the holes in

the actuator assembly

and lifting the quick

coupling. Release the

quick coupling when

the dolly head is

completely engaged.

5. Close the pressure

relief valve on the

pump tightly.

6. Ensure the pump is on

a well-supported

horizontal surface. If it

is necessary to place

the pump on a vertical

surface, position the

unit so the pump hose outlet is in the down position to

prevent air from being pumped into the actuator.

7. Begin pumping the pump handle until the black indicator on

the pressure gauge starts to move. Continue pumping at a

uniform rate of no more than 1 MPa (150 psi) per second

until the actuator pulls the dolly from the coating.

8. Immediately following the pull, open the pressure relief valve

on the pump to release the pressure. The red “drag”

indicator on the pressure gauge will maintain the maximum

pressure reading.

Note:

An imprecise return of the black indicator to zero does

not necessarily mean the gauge is out of calibration. If all

pressure has been relieved but indicator still does not return

to zero, simply tap the gauge on its case with a finger or

elevate pressure and release again.

9. Record the pull off pressure and mark the dolly for future

qualitative analysis.

Analyzing Results

Test results can be considered 100% valid when the coating is

completely removed from the substrate and remains adhered to

the adhesive on the dolly. When only a portion of the coating is

removed, specific results should be analyzed including the

fracture pattern to determine the cohesive properties of the

coating and adhesion properties between the dolly and adhesive,

adhesive and coating, distinct coating layers, and coating and

substrate.

Maintenance

Refer to the Pump Operating Instructions (included) for

maintenance information.

Warranty

The manufacturer fully warrants its products against defects in

workmanship or materials for a period of one year from date of

purchase. In the event that a tester is found to be defective,

return the product with proof of purchase to your dealer, and the

defective product will be repaired or replaced at the

manufacturer’s option.

No responsibility is assumed for incidental or consequential

damages.

The warranty is voided if the tester or its components have been

disassembled or tampered with.

Data subject to change without notice

© DeFelsko Corporation USA 2000 • All Rights Reserved • Patents applied for • Printed in USA

This manual is copyrighted with all rights reserved and may not be reproduced or transmitted, in

whole or part, by any means, without written permission from DeFelsko Corporation.

DeFelsko and PosiTest are trademarks of DeFelsko Corporation registered in the U.S. and in

other countries.

Every effort has been made to ensure that the information in the manual is accurate. DeFelsko is

not responsible for printing or clerical errors.

DeFelsko Corporation

802 Proctor Avenue, PO Box 676

Ogdensburg, NY 13669 USA

Tel: 315-393-4450 – Fax: 315-393-8471

Email: [email protected] – web: www.defelsko.com

The Measure of Quality