Johnson Level & Tool Mfg. 40-6210 User Manual

Page 3

3

3

Using an inside caliper, measure the difference in endwall thickness between the two sheaves being

aligned. The measurement can be easily taken using the depth gauge end of the caliper. Place the butt end

of the caliper against the machined side face of the sheave and extend out the depth micrometer end of the

caliper until it contacts the side of the V-belt. Measure each sheave. If the difference is larger than 1/64”

.015”), then compensate for it using the targets, as explained in Grooved Targets section above.

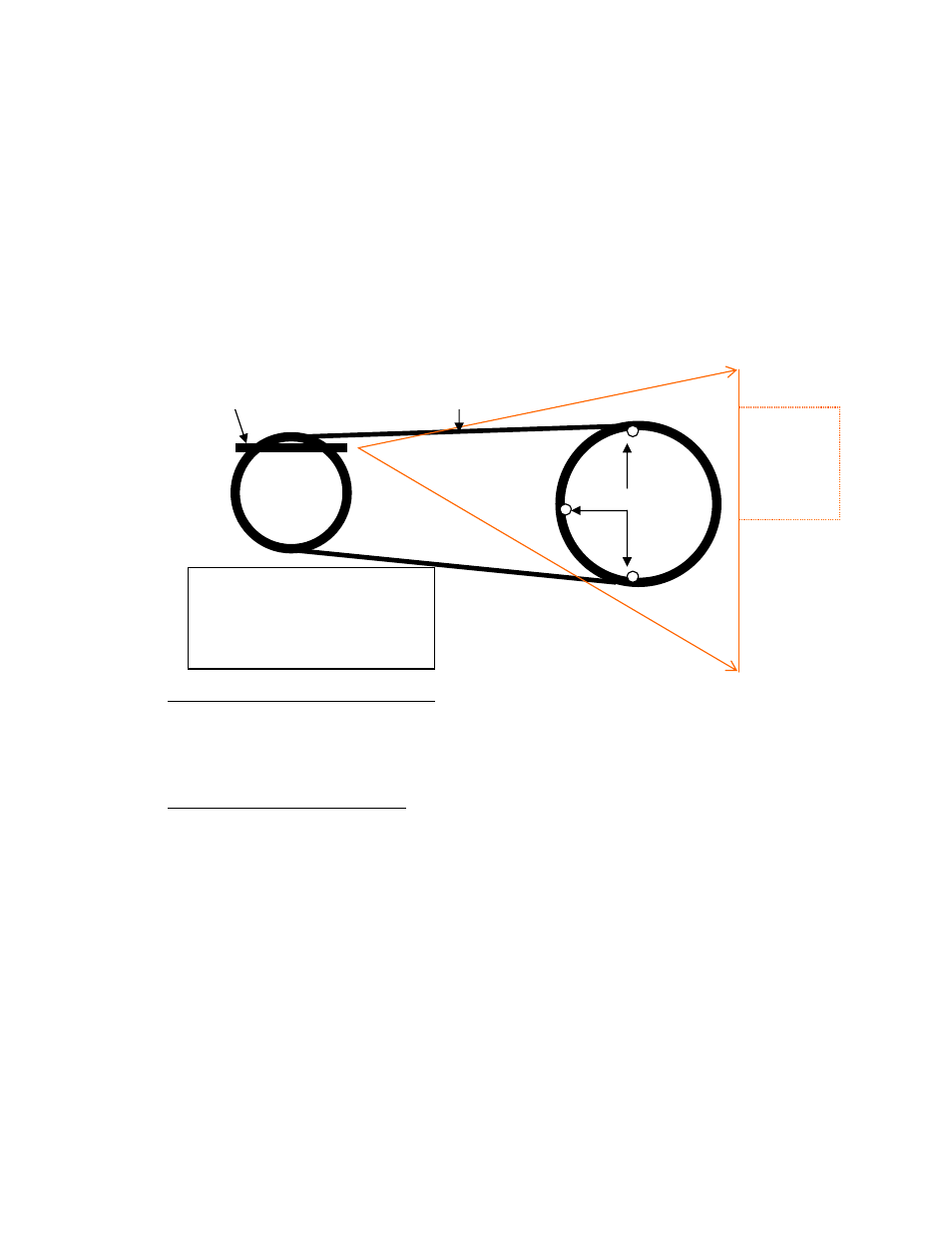

Mount the PowerLine™ Laser and targets as figured below. Note that the laser emitter can mount either on

the small sheave or the large sheave based on field conditions, however, it is preferable to mount it on the

smaller diameter sheave. Locate the PowerLine™ laser on the sheave rim so it is adjacent to the tight side

of the belt. Point the laser line so it projects along the tight side of the belt towards the companion sheave.

Mount the three targets on the companion sheave at the 12, 9, and 6 o’clock positions as shown. Make sure

each target’s magnetic bottom is extended full turn (1/16”) from flush when sheaves have equal thickness,

or, if you are compensating for sheave endwall thickness differences, make sure your adjustment is done

equally on all three targets.

3. Turning the PowerLine™ Laser on and off

Turn on the PowerLine™ laser by rotating the battery compartment end cap clockwise until the battery

circuit is energized. To turn off the laser, rotate the end cap counterclockwise and back off one full turn.

This will ensure laser does not energize inadvertently in storage. Spare batteries are included in the case.

4. Align Equipment Using Laser Targets

Align equipment until the projected laser line strikes the center of the groove on all three targets

simultaneously. This indicates excellent alignment. If the targets are not “aligned”, then the procedure for

correcting any misalignment is as follows:

The misalignment visible between the 12 o’clock and 6 o’clock targets indicates amount of “vertical”

angular and parallel misalignment. To correct this misalignment, loosen, shim, and tighten base bolts

and/or adjust the sheave axial positions on their respective shafts until “vertical" misalignment is corrected.

The laser line should now strike the target center of both the 12 o’clock and 6 o’clock targets.

The misalignment visible between the 12 o’clock and 6 o’clock targets and the 9 o’clock target indicates

amount of “horizontal” misalignment. To correct, move the 6 o’clock target to 3 o’clock. Adjust the

position of the front and/or back feet of one or both of the machines horizontally to correct for horizontal

misalignment until the laser line strikes the target centers of both the 3 o’clock and 9 o’clock targets

simultaneously. Verify you are also hitting the center of the 12 o’clock target. Remember to test and

adjust for proper belt tension while aligning. After adjustment, the laser line should now strike the bottom

of the groove of all three targets, indicating excellent alignment.

Tight Side of Belt

PowerLine™ Laser

3 Targets

Visible

laser line is

projected

over target

area

Note:

It is preferable to place the

PowerLine™ laser onto the

smaller diameter sheave whenever

possible.