Warning – FallTech 7448L User Manual

Page 2

Section 6 - Visual Inspection Before Each Use

Section 11 - On Product Labels and Warnings

To make sure that this FallTech Anchor will perform properly as part of a PFAS or

PRS, it is important that you visually inspect it BEFORE USE.

What to look for when visually inspecting Anchor Strap:

1.

Look to see that the steel D-ring is not broken, damaged or distorted in shape.

There should be no corrosion, cracks, worn parts or sharp edges.

2

. Look to see that the webbing portion of the Concrete Embed Anchor Strap has no

broken fibers or fraying. Look for abrasion, tearing, burns, mold, discoloration or cuts.

Also look for torn or loose stitching.

2

. Look to see that each of the other FallTech PFAS or PRS components

(harnesses, rope grabs, lifelines, tie-offs, etc.) are ready for use by visually inspecting

each part according to the instructions provided with that product.

4. For proper comatibility of the anchorage end snap hook, the D-ring, O-ring or con-

nection component of the anchorage connector should have an inside diameter of at

least 2-1/2 times the gate opening on the snap hook.

3

. Record the results of your inspections in the log in section 11 of this manual and on

the inspection

grid on the serial # label of your FallTech Concrete Embed Anchor.

Warning!

If this anchor is damaged, or has been subjected to fall arrest

(or

equivalent) forces, it must be removed from service immediately and

destroyed.

NOTE:

Harsh environments and weather, prolonged use, and other extreme working

conditions may require you to have this anchor inspected by a competent person other

than yourself at least twice a year.

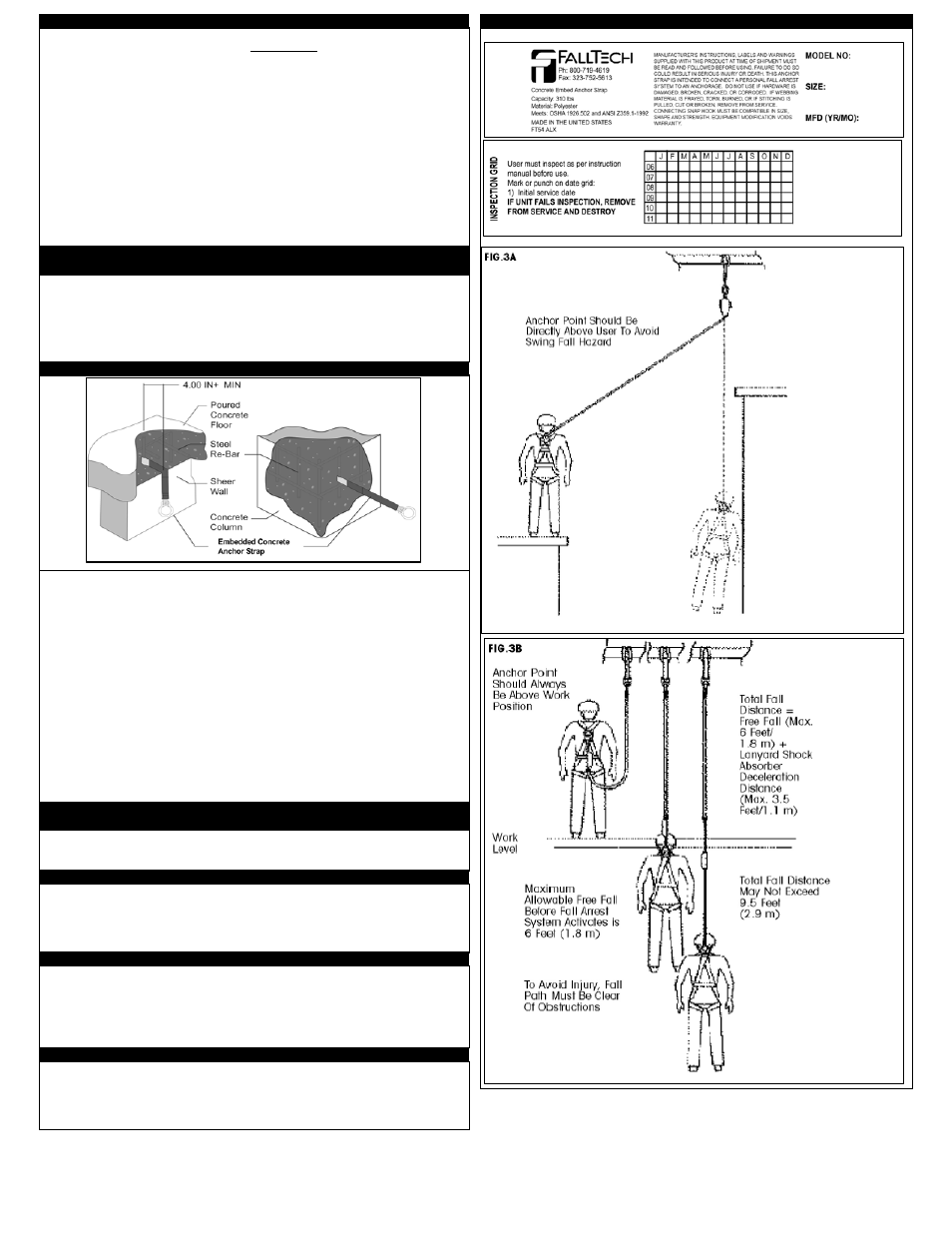

Section 7 - How to Use Concrete Embed Anchor Strap

This anchor is part of a comprehensive PFAS or PRS. It must be used in conjunction

with a Full Body Harness with back D-ring and a Shock Absorbing Lanyard/Self-

Retracting Lifeline that limits freefall to 6 feet or less. When used as a component of a

PRS, it must be used with a Full Body Harness or Work Positioning Belt and a

Positioning Lanyard.

1. Select a location for the Concrete Embed Anchor Strap that provides the best safety

to the user. If in doubt, contact a qualified or competent person for further information.

2. After a section of shear wall or concrete column has been poured and allowed to cure,

place the looped end of the anchor onto a vertical piece of steel rebar (see above).

3. Once anchor(s) are in place, continue pouring of concrete, allowing concrete to fully

cure.*

4. After removing forms, anchors will remain on the face of the column or in between

the seems of shear walls.

REINFORCED CONCRETE FLOOR SLAB - A 3' length of rebar may be passed through

the loop end of an anchor strap and wire tied to remain in place tight to the underside of

the upper mat of rebar providing 3.5" clearance. Concrete may then be poured; anchor

strap becomes cast in place for use after curing as a fall protection tie-off point.

*DO NOT USE THIS ANCHOR UNTIL CONCRETE IS ALLOWED TO CURE. FAILURE

TO ALLOW CONCRETE TO CURE PROPERLY COULD RESULT IN SERIOUS

INJURY OR DEATH.

Section 8 - How to Remove Concrete Embed Anchor Strap

After all potential fall hazards have been removed from the work area, the anchor

must be removed from service. Remove anchor using scissors or a utility knife, cutting

anchor off at the concrete seam.

DO NOT REUSE CONCRETE EMBED ANCHOR STRAP. AFTER REMOVAL FROM

WORK AREA, DISPOSE OF ANCHOR STRAP.

Section 9 - Proper Connection

For connection to the Concrete Embed Anchor Strap, use a self-locking snap hook or

double-locking carabiner ONLY. Make sure connections are fully closed. If utilizing a

shock absorbing lanyard, connect shock absorbing component to full body harness. If

using a self retracting lifeline, connect double-locking snap hook or carabiner to full

body harness. Make sure flow of cable/web is unhindered. NEVER connect more than

one PFAS or PRS to a single anchor.

Section 10 - Product Specifications

Hardware: Plated alloy steel, 5000lbs minimum breaking strength

Webbing: Polyester with a minimum breaking strength 9800lbs

Wear Pad: Polyester webbing used for wear resistance only

Capacity: 425lbs - one person, including clothes, tools, etc

Meets OSHA 1926.500 and ANSI Z359.1 requirements

Warning!