Fan / cone alignment, Fanwall technology, Assembly – Mammoth 7 to 24 Tons: High Efficiency, Superior IAQ Twin and Quad Circuit Horizontal and Vertical (M-Vintage) User Manual

Page 9

9

MAMM-WSHP-IOM-1MA (November 2011)

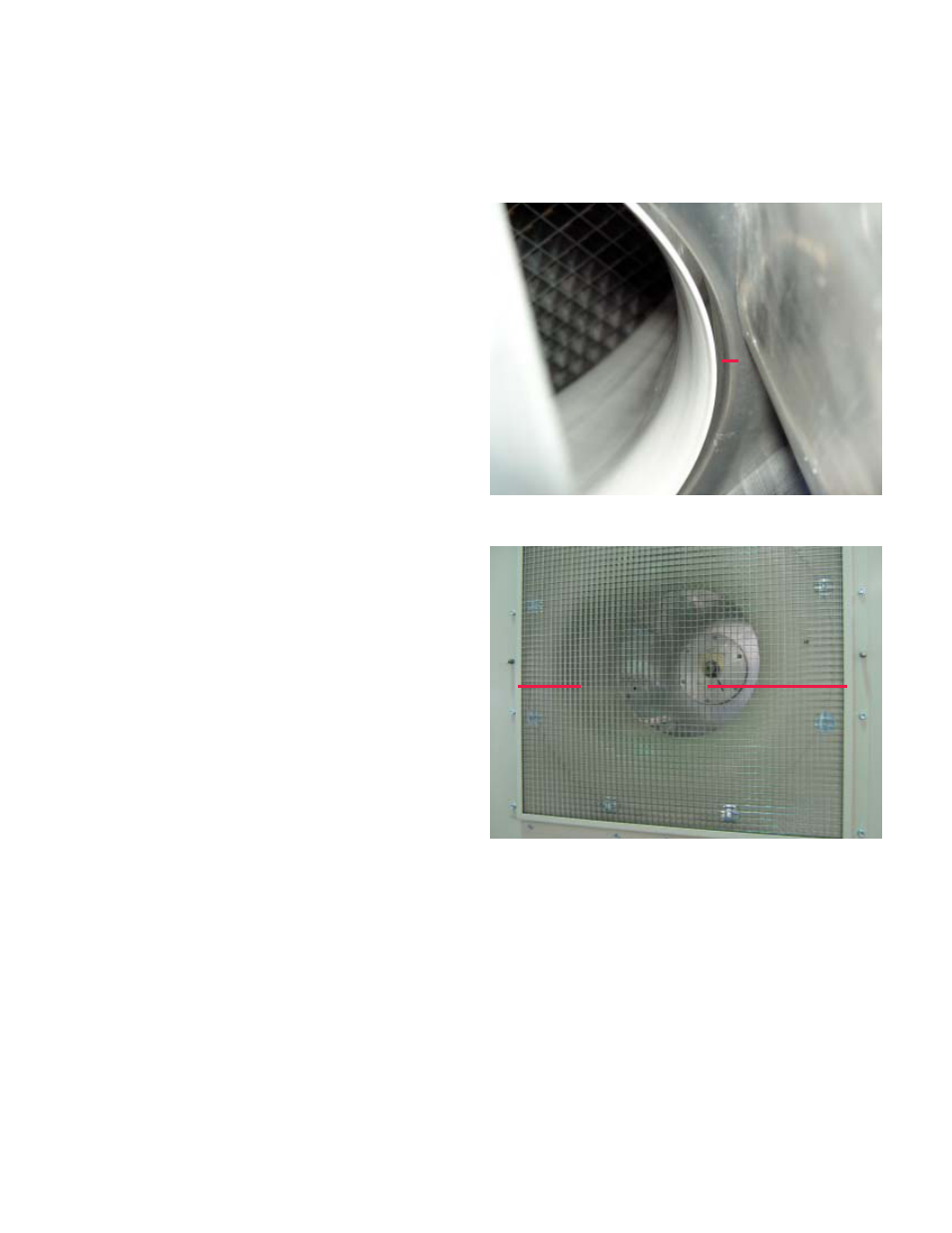

Fan / Cone Alignment

1. Temporarily attach the cone to the cell inlet using the

screws and washers provided, or slightly loosen

the screws holding the cone if already installed.

Use a minimum of four screws for this step.

a. Refer to the fan wheel overlap drawings pro-

vided to determine where to set the wheel with re-

spect to the cone.

b. Adjust the amount of overlap by moving the mo-

tor pedestal forward or backward to line up the

cone with the wheel (wheel/cone overlap is de-

signed to insert the cone 50% of the distance of the

rolled shroud lip on the wheel). Once you have the

wheel approximately located, tighten the ½” pedes-

tal bolts to 90ftlbs.

2. Center the cone in the wheel shroud.

a. The cone alignment can be a tedious process as

there are no tools that effectively work to align the

cone. It is a hands on process to align the cone.

Mammoth cones have a running clearance of

about 1/16" (see Figure 1).

b. Start by loosening the four screws that were

used to hold the cone for the depth alignment. Hold

the cone with one hand and with the other use a

drill to attach a screw to hold the cone in place.

Feel between the wheel inlet shroud and the cone

and set the gap to approximately 1/16" and tighten

the screw in that location (top of the cone is usually

the best place to start). At this point you should be

able to move the cone about that screw location,

adjusting the cone on the left or right until there is

approximately a 1/16" gap.

c. Spin the wheel by hand at this point to check for

any clearance issues. If the wheel spins clear,

tighten the remaining screws on the cone. Check

that the wheel spins clear after tightening each

screw.

3. Attach the inlet airflow straightener using the formed

angle brackets (see Figure 2).

a. Start by loosely installing (don’t tighten screws

all the way) the bottom angle bracket. Set the air-

flow grid on the angle bracket. Align the side of the

grid with the end of the bracket.

b. Install either vertical angle bracket loosely and

check fit up.

c. Install the two remaining brackets and tighten

(see Figure 2).

FANWALL TECHNOLOGY

®

Assembly

Figure 1—FANWALL

®

cone alignment

Figure 2—Inlet airflow straightener

TYPICAL FAN-CONE

CLEARANCE

AIRSTRAIGHTENER

FIGURE 2

AIR STRAIGHTENER

ANGLE BRACKERS

FIGURE 1