MAHLE RTI TX600 User Manual

Page 9

RTI Technologies, Inc.

November 19, 1999

Page 8

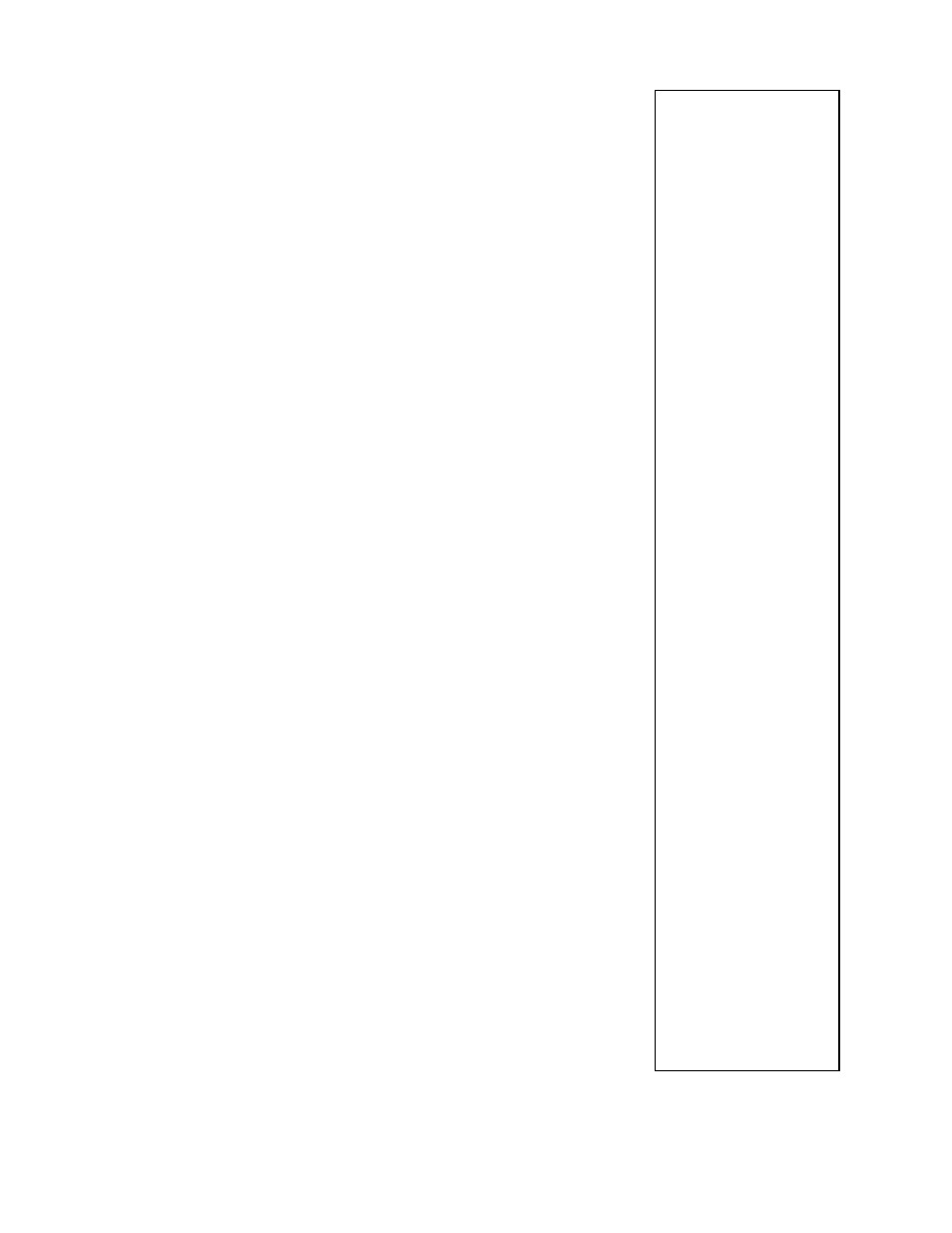

0

F

PSIG

30

42

32

44

34

46

36

48

38

50

40

52

42

54

44

57

46

59

48

61

50

64

52

66

54

69

56

72

58

74

60

77

62

80

64

83

66

85

68

88

70

92

72

95

74

98

76

102

78

105

80

108

82

112

84

115

86

118

88

123

90

127

92

130

94

135

96

138

98

143

100

147

102

150

104

155

106

160

108

165

110

168

112

173

114

178

116

183

118

188

120

193

5.

Determine the room temperature. A Pocket Thermometer is

convenient for this measurement.

6.

Locate the pressure (PSIG) corresponding to this room

temperature (

0

F) in Table at right.

If Pressure Gauge indicates higher than that determined from the

table...

SLIGHTLY & SLOWLY open Valve on Yellow Service

Hose connected to INLET of TX600 until the Pressure

Gauge pressure equals that shown in the table. Any Non-

condensable Gas will be vented through the Oil Drain

Valve.

NOTE...

A copy of the Temperature/Pressure Table is located on the rear

of the TX600 for easy reference.

7. Close the Oil Drain Valve.

8. Open Valve on Yellow Service Hose connected to the INLET of

TX600 for approximately 5 seconds; then close. This permits any

residual Non-condensable Gas to be recirculated for reprocessing

during the next recycle procedure.

9. Close VAPOR Valve on Refrigerant Cylinder.

Non-condensable Gas has now been removed and the refrigerant is ready

for charging back into an A/C System.

CAUTION...

The preceding Recycling and Purge Procedures allow the Yellow

Service Hoses to remain permanently connected to the TX600.

Disconnecting either hose from the TX600 may vent refrigerant

unnecessarily or introduce air into the system and should be avoided.

The Yellow Service Hoses should remain connected to the TX600

unless repair or transport is required.

SEE NEXT PAGE FOR ALTERNATE PROCEDURE...