Oil drain & air purge – MAHLE RTI RRC770 User Manual

Page 9

RTI Technologies, Inc.

8

September 28, 1999

Page 8

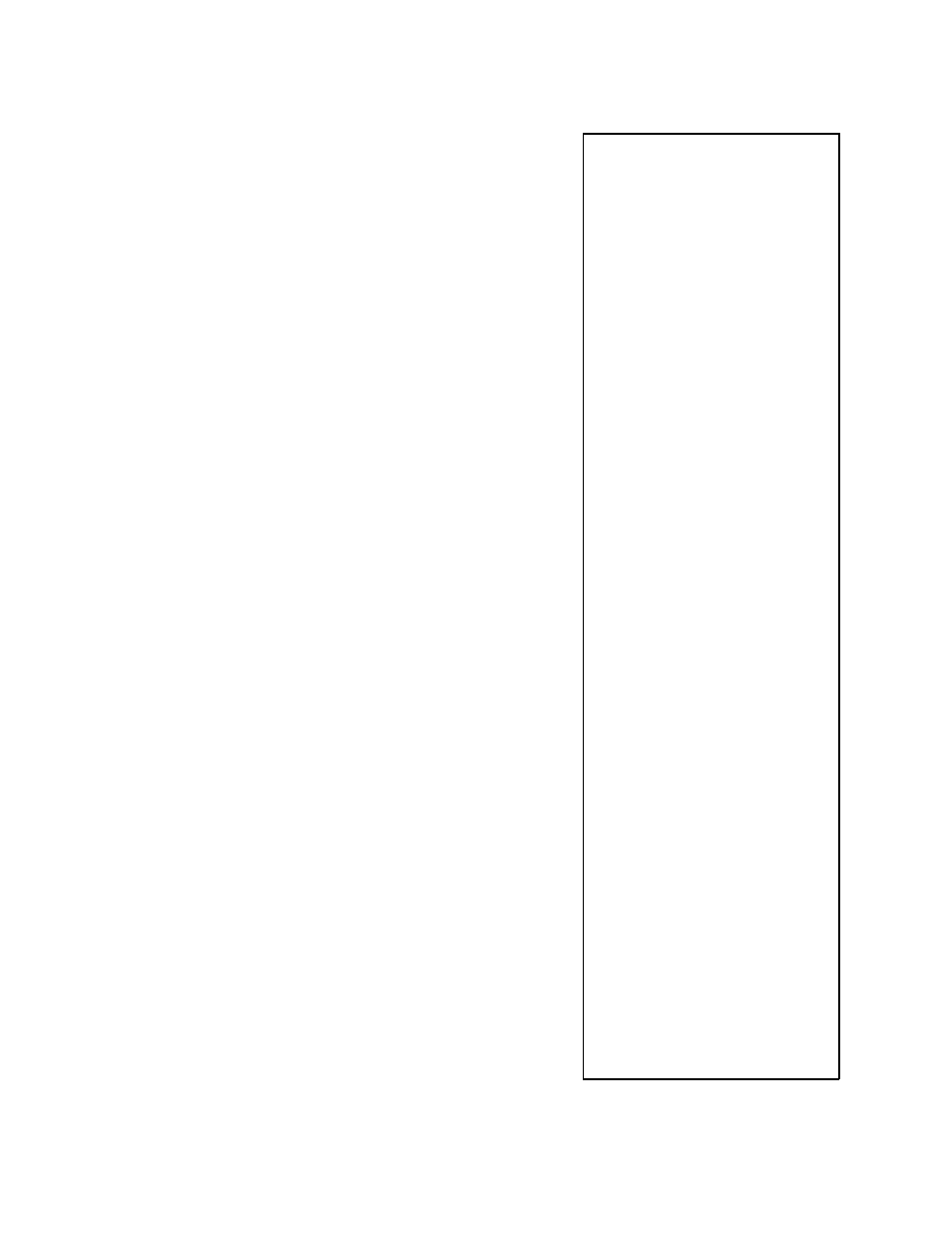

0

F

R12

R134a

30

42

40

32

44

42

34

46

44

36

48

46

38

50

49

40

52

51

42

54

54

44

57

56

46

59

59

48

61

61

50

64

64

52

66

67

54

69

70

56

72

72

58

74

76

60

77

78

62

80

82

64

83

85

66

85

88

68

88

92

70

92

95

72

95

97

74

98

104

76

102

107

78

105

110

80

108

114

82

112

118

84

115

123

86

118

127

88

123

130

90

127

135

92

130

140

94

135

145

96

138

148

98

143

153

100

147

157

102

150

163

104

155

167

106

160

173

108

165

180

110

168

185

112

173

190

114

178

195

116

183

200

118

188

207

120

193

213

Purge Chart

OIL DRAIN & AIR PURGE

Oil and Non-condensable Gas (Air) are

separated from the recovered refrigerant

and MUST be removed following EACH

recycling procedure as follows:

Note: RRC770 must be connected to power

source.

1. Press and hold the Purge Air switch

(below the Contamination Monitor

Gauge) for 5 seconds, and then release

it.

2. Slowly open the Oil Drain Valve (below

cylinder shelf on rear left side of

RRC770) to drain any oil which may have

been removed from the A/C system. A cup

is provided to collect the oil.

Unless the A/C System had previously

been overfilled, the RRC770 will

typically not remove more than a

tablespoon of oil, making replenishment

unnecessary.

LEAVE THE OIL DRAIN VALVE OPEN...

3. Determine the room temperature.

4. Locate the pressure (PSIG) corresponding

to this room temperature (

0

F) in the

chart on the top of the RRC770. This

chart is reproduced at the right.

If the pressure indicated on the

Contamination Monitor Gauge is greater

than that determined from the chart:

Press and hold the Purge Air Switch

until the Contamination Monitor Gauge

pressure goes down to the pressure

determined from the chart. Any Non-

condensable Gas will be vented through

the Oil Drain Valve at this time.

5. Close the Oil Drain Valve.

6. Press and hold the Purge Air switch for

5 seconds. This permits any residual Non-

condensable Gas to be recirculated for

reprocessing during the next recycle

procedure.