Purging air from the erc cylinder – MAHLE RTI TX200 User Manual

Page 8

Page 7

0

F

R12

R134a

30

42

40

32

44

42

34

46

44

36

48

46

38

50

49

40

52

51

42

54

54

44

57

56

46

59

59

48

61

61

50

64

64

52

66

67

54

69

70

56

72

72

58

74

76

60

77

78

62

80

82

64

83

85

66

85

88

68

88

92

70

92

95

72

95

97

74

98

104

76

102

107

78

105

110

80

108

114

82

112

118

84

115

123

86

118

127

88

123

130

90

127

135

92

130

140

94

135

145

96

138

148

98

143

153

100

147

157

102

150

163

104

155

167

106

160

173

108

165

180

110

168

185

112

173

190

114

178

195

116

183

200

118

188

207

120

193

213

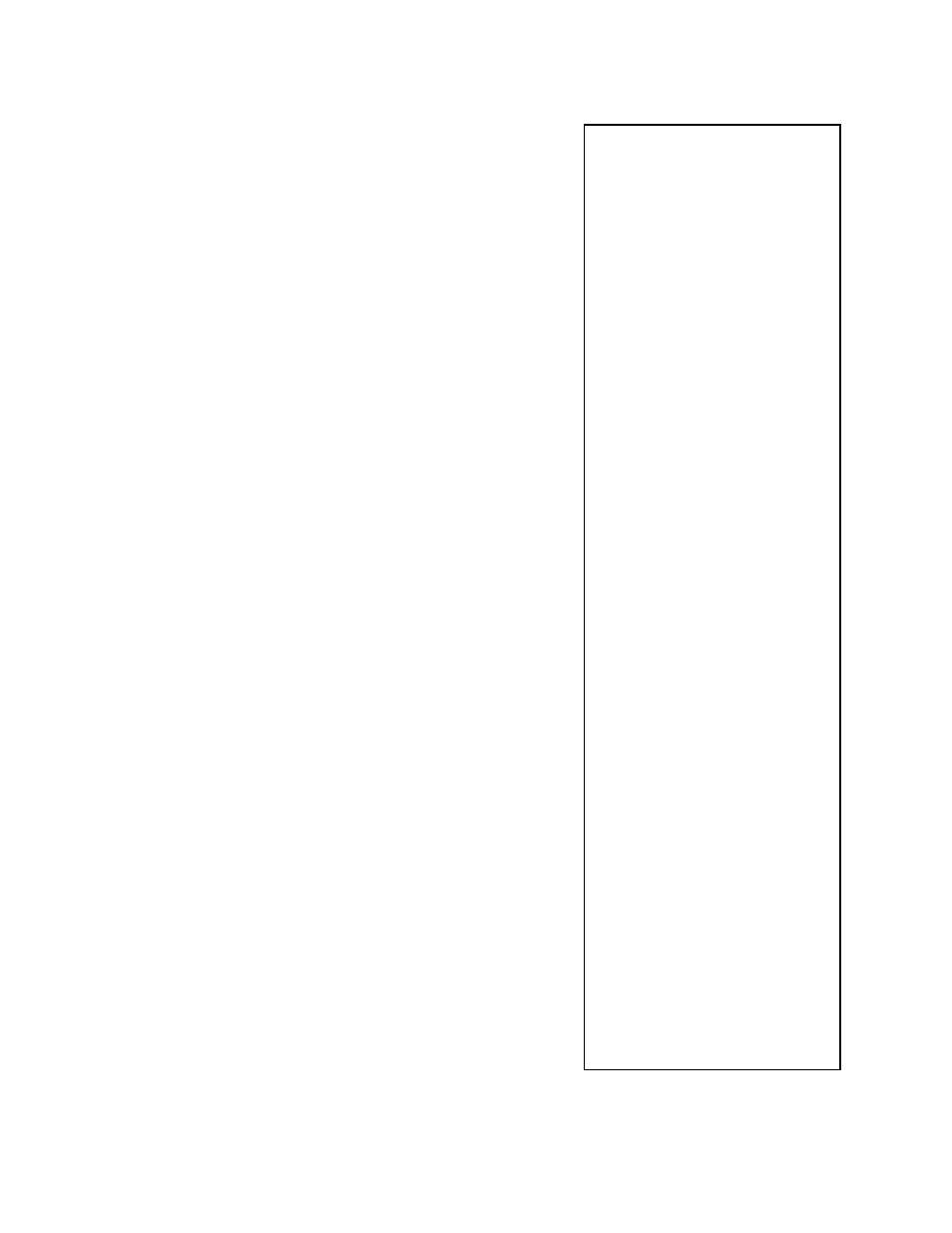

Purge Chart

PURGING AIR FROM THE ERC CYLINDER

Refrigerant recovered into the ERC Cylinder may

also contain Air. This Air will increase the pressure

in the ERC Cylinder and slow recovery. Large

quantities of Air may even cause the TX200 to stop

recovering due to a High-Pressure-Shutdown.

Check the pressure in the ERC Cylinder to

determine the need to purge Air as follows:

Connect the High Side Gauge (on Gauge Manifold)

to the Vapor Valve of the ERC Cylinder. Determine

the ambient temperature and compare the gauge

pressure to the pressure shown in the Air Purge

Chart to the right.

If the ERC Cylinder pressure is greater, slowly open

the Gauge Manifold Valve and allow Air to slowly

escape until the pressure equals that shown in the

chart.

The above purge process can be performed

anytime during a recovery and while the ERC

Cylinder is still above ambient temperature after a

recovery procedure.

After the ERC Cylinder has cooled to ambient

temperature, the Air can be purged to the pressure

in a Standard Refrigerant Pressure/Temperature

Chart.

NOTE:

A High-Pressure-Shutdown can be detected by

noting that the Compressor-On Light goes OFF and

there is still positive pressure at the Inlet of the

TX200.

The Condenser Fan will continue to run and the

TX200 Compressor may cycle Off and On as the

Outlet Pressure rises and falls.