Component range, Vision capability, Board handling – MYDATA MY200HX User Manual

Page 2: High precision mounthead – midas, High speed mounthead – hydra z8, Electrical verifier (optional), Dual vision system (optional), Linescan vision system, System features my200hx, Inline conveyor

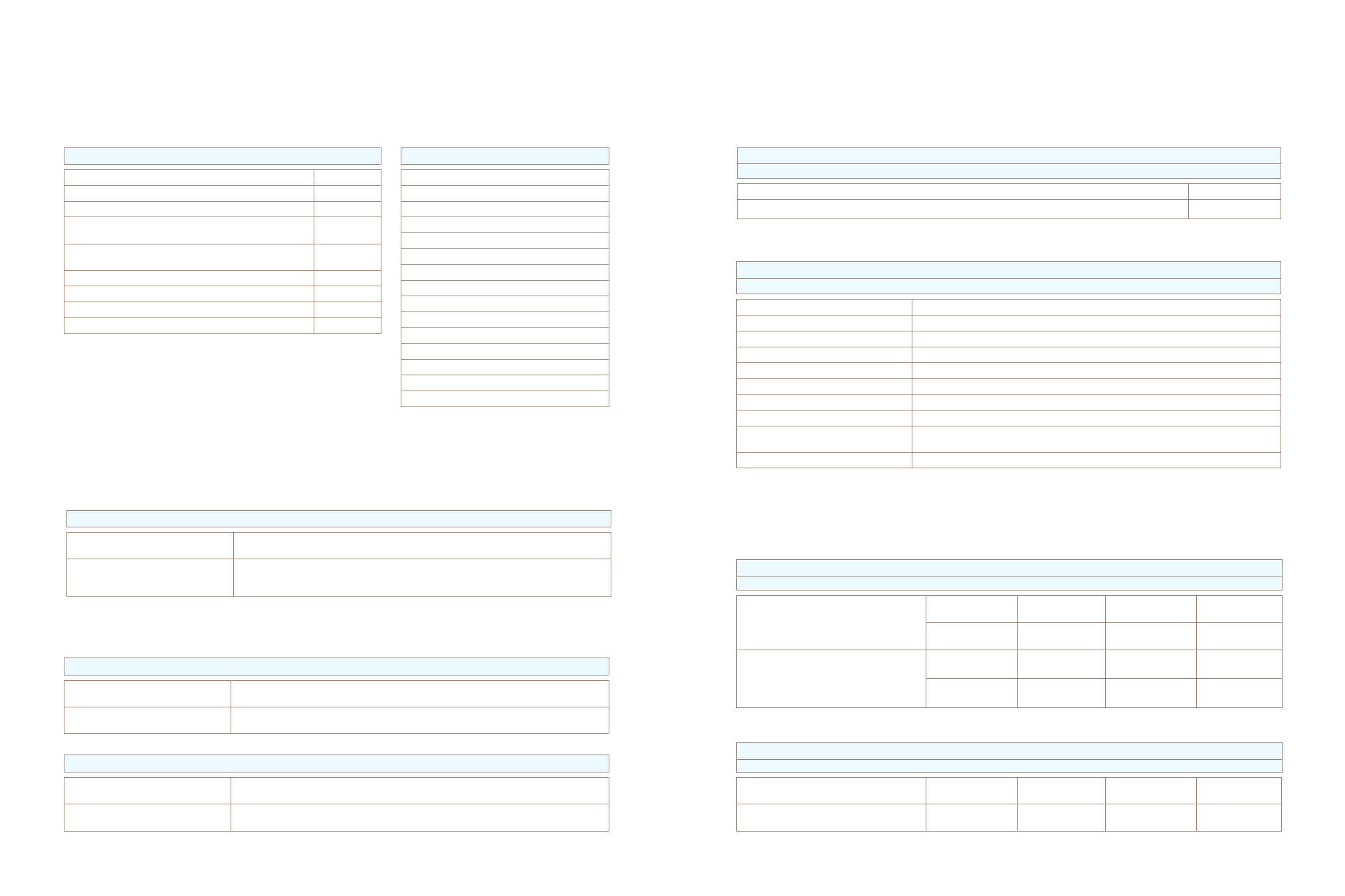

MY200-SerieS P&P SPecificatioN – MY200HX

coMPoNeNt raNge

HigH PreciSioN MouNtHead – MidaS

component range

chip (from 01005), Soic, Sot, Sod, tSoP, MeLf, cSP, QfP (low profile), Bga (low profile),

dPaK, flip chip, odd shape

component Specification

Min: 0.4 x 0.2 mm (0.016” x 0.008”) (01005)

Max: 56 x 56 x 2.54 mm (2.20” x 2.20” x 0.10”)

Max: component weight: 140 g

(1)

1) depending on mounthead, mount tool, package, and production altitude.

HigH SPeed MouNtHead – HYdra z8

component range

chip (from 0201), So16, Sot223, MeLf, Sod, tSoP

component Specification

Min: 0.6 x 0.3 mm (0.02 x 0.01”) (0201)

Max: 18.6 x 18.6 x 2.54 mm (0.73 x 0.73 x 0.10”) (PLcc44)

eLectricaL verifier (oPtioNaL)

component range

resistor, capacitor, unipolar capacitor, diode (forward voltage, reverse current),

zener diode (voltage drop), transistor (current gain)

verification time

on-the-fly

viSioN caPaBiLitY

duaL viSioN SYSteM (oPtioNaL)

component

type

camera

max

active

field

of

view

min

pitch

min

lead

width

Leaded components

Svc

(1)

56 x 52 mm

(2.20” x 2.04”)

0.40 mm (16 mil)

0.20 mm (8 mil)

Hrc

(2)

15 x 15 mm

(0.59” x 0.59”)

0.10 mm (4 mil)

0.05 mm (2 mil)

Bumped components

Svc

(1)

56 x 52 mm

(2.20” x 2.04”)

0.50 mm (20 mil)

0.25 mm (10 mil)

Hrc

(2)

15 x 15 mm

(0.59” x 0.59”)

0.16 mm (6.3 mil)

0.08 mm (3.1 mil)

LiNeScaN viSioN SYSteM

component

type

camera

max

active

field

of

view

min

pitch

min

lead

width

Leaded components

Lvc

(1)

56 x 56 mm

(2.2” x 2.2”)

0.20 mm (8 mil)

0.10 mm (4 mil)

Bumped components

Lvc

(1)

56 x 56 mm

(2.2” x 2.2”)

0.30 mm (12 mil)

0.15 mm (6 mil)

1) Standard vision camera in dual vision system (dvS).

2) High resolution camera in dual vision system (dvS).

1) Line scan vision camera.

feeder caPacitY

PLaceMeNt SPeed aNd accuracY

SYSteM featureS

SYSteM featureS MY200HX

on-the-fly mount order optimization

vision autoteach with snap-to-grid

automatic illumination settings

intelligent feeder concept – agilis

automatic feeder and component recognition

on-the-fly feeder loading

dynamic feeder positions

automatic board stretch compensation

automatic conveyor width adjustment

intelligent surface impact control

tool collision avoidance

Multi-user, multi-tasking system software

open software interfaces for factory integration

SQL database engine

Programmable light settings fiducial camera

PLaceMeNt SPeed aNd accuracY – MY200HX 10/14

rated Speed

(1)

50 000 cPH

iPc 9850 chip Net throughput

(2,3)

40 000 cPH

iPc 9850 chip tact time

(3)

0.080 s

iPc 9850 chip repeatability 3s (X, Y, theta)

(3)

30 µm, 1.8°

(6)

45 µm, 1.8°

iPc 9850 chip accuracy @ cpk = 1.33 (X, Y, theta)

(5)

50 µm, 2.6°

(6)

75 µm, 2.6°

iPc 9850 fine Pitch Net throughput

(2,4)

4 500 cPH

iPc 9850 fine Pitch tact time

(4)

0.700 s

iPc 9850 fine Pitch repeatability 3s (X, Y, theta)

(4)

21 µm, 0.05°

iPc 9850 fine Pitch accuracy @ cpk = 1.33 (X, Y, theta)

(4,5)

35 µm, 0.09°

the above specification achieved with a machine configuration including high precision mounthead (Midas),

high speed mounthead (HYdra z8), line scan vision system (LvS) and inline conveyor t4.

the iPc 9850 net throughput and accuracy numbers are obtained simultaneously, with the same machine settings.

the rated speed value is obtained under conditions optimized for speed.

1) depending on component and application.

2) according to iPc 9850. Net throughput = (no of parts x 3600) / (board build time + board transfer time).

3) according to iPc 9850 0402c verification panel.

4) according to iPc 9850 QfP64/QfP100 verification panel.

5) according to iPc 9850 cpk 1.33 = 4s + offset.

6) Small chip settings, recommended for 0201 (0.6 x 0.3 mm) and below.

Board HaNdLiNg

iNLiNe coNveYor

t4

Maximum Board Size

575 x 508 mm (22.6" x 20")

Maximum Board Size with ML adaptor

(1)

554 x 443 mm (21.8" x 17.4")

Minimum Board Size

(2)

70 x 50 mm (2.7" x 2")

Board thickness range

0.4 - 6.0 mm (0.016" - 0.24")

Board edge clearance top and Bottom

3.2 mm (0.13")

top Side clearance (max)

2.54 mm (0.10")

Bottom Side clearance (max)

32 mm (1.25")

Maximum Board Weight

8 kg (17 lbs)

Board transfer Height

conforms to SMeMa standard for board transfer height.

Height adjustable from 892 to 987 mm (35.1” to 38.9”).

operation Mode

inline, manual, inline odd-board, left-to-right / right-to-left.

1) optional. Suitable for irregular sized and odd shaped boards.

2) recommended board train specification: 90 x 50 mm (3.5” x 2”) board size, 1.6 mm (0.06”) thickness.

feeder caPacitY 8 MM taPe

t4

MY200HX-10

96

MY200HX-14

160