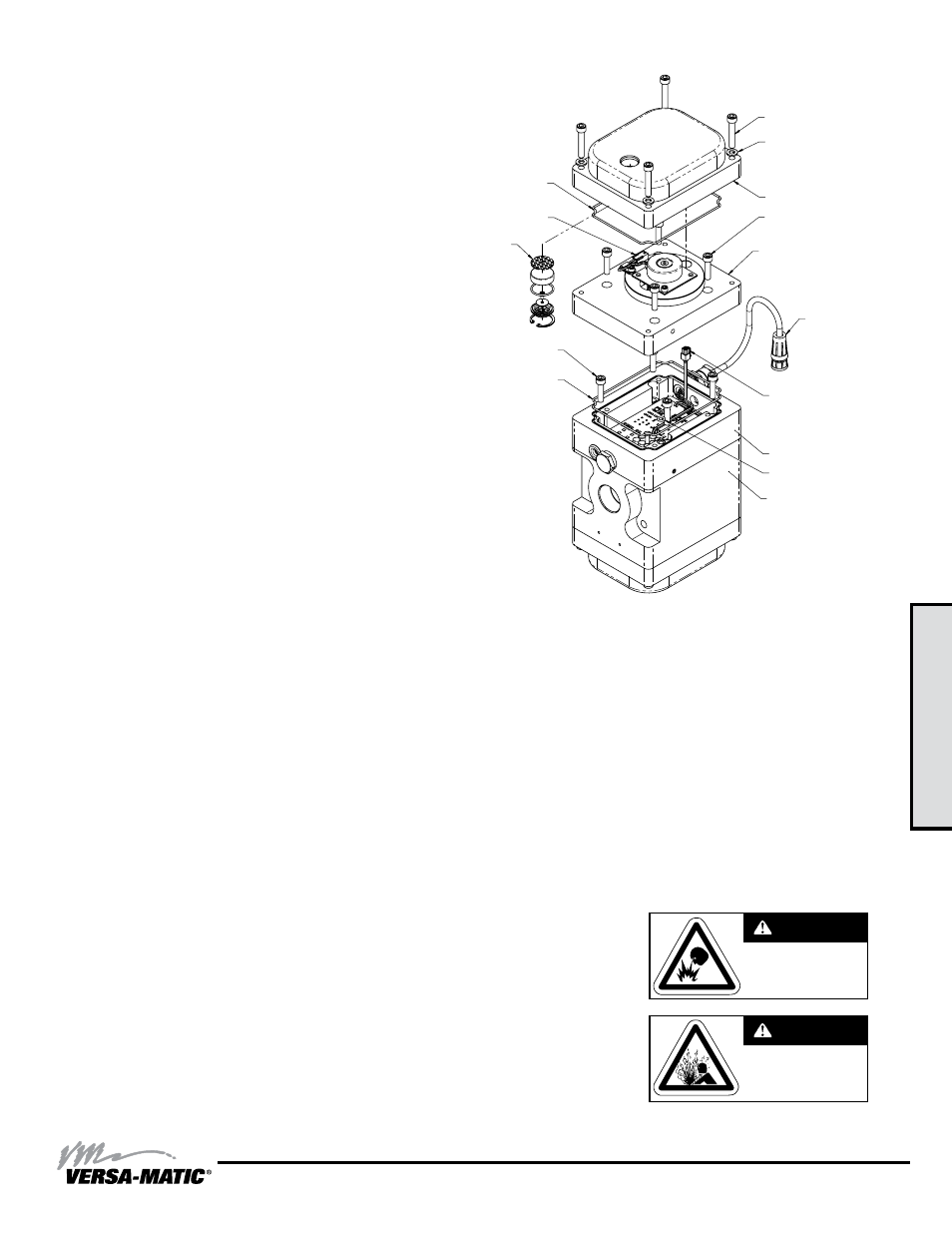

Airvantage servicing - power generation module, Exp view – Versa-Matic 3 Clamped Metallic Hazardous Service Ball Valve (RE3) User Manual

Page 23

re3mdlAsmATEXC-rev0614

www

.

versamatic

.

com

3: EXP

VIEW

Model RE3 Metallic Clamped •

20

AirVantage Servicing - Power Generation Module

To service the power generation module, first shut off and

bleed the air being supplied to the pump. For safety purposes

the air supply line should be disconnected from the pump.

Then shut off the suction and discharge lines to the pump.

Bleed the pressure from the pump suction and discharge lines

and remove the lines from the pump. During the servicing of

the AirVantage, consult the “AirVantage Composite Repair

Parts Drawing”.

Step #1: Remove the Patch Cable

Twist the ribbed portion of the patch cable connector

in a counterclockwise direction, until it unthreads from

the connector. The cable can then be removed from the

intermediate..

Step #2: Remove the AirVantage from the Pump

Use a ½” socket and remove the four 5/16-18 x 5 1/2 cap

screws that hold the AirVantage to the pump. Remove the two

chamber bolts/nuts that are holding the right side bracket to be

able to remove the right bracket and AirVantage unit from the

pump. Be sure to support the weight of the AirVantage while

removing the last cap screw. After the AirVantage is removed

from the pump, set the unit down on the cover located on the

top. Inspect the o-ring between the poppet valve

and the adapter plate for damage.

Step #3: Access the Power Generation Module

Use a 5mm hex-key wrench and loosen the four M6 x 35mm

socket head cap screws securing the bottom cover. Lift the

bottom cover off, exposing the power generation module.

There is a molded o-ring seal located on the underside of the

cap. Make sure the o-ring stays located within the groove.

If the power generation module needs to be replaced, unplug

the connector that connects the power generator to the control

board. Use a 4mm hex-key wrench to loosen the four M5 x

25mm socket head cap screws. The power generation module

should now be loose. Carefully lift the power generation

module off the rest of the assembly, making sure that the

control board wire and connector slips through the hole in

the power generation case.

"AirVantage Caution" - Take caution not to loosen the

o-ring that seals between the components.

Step #4: Reinstallation

When reinstalling the new module make sure to feed the

control module wire through the hole in the power generation

case. Install the four M5 x 25mm socket head cap screws and

tighten to 6.8 N-M.

“AirVantage Caution” – Be sure to reattach the connector

from the power generator to the control board.

Reinstall the bottom cover, making sure the o-ring seal is still

in the groove. Tighten the four M5 x 25mm socket head cap

screws to 3.4 N-M.

Reinstall the top cover, making sure the o-ring seal is still in the

groove. Tighten the four M6 screws. Reinstall the AirVantage

right bracket, chamber bolts/nuts and four 5/16-18 x 5 1/2 cap

screws, torque to 90 in-lbs.

“AirVantage Caution” – Be sure to reattach the patch cable

connector that connects the AirVantage module to the

intermediate.

Note: Refer to Composite Repair Parts

List on page 23 for part numbers

VALVE, POPPET

CONTROL MODULE

CASE, POWER GENERATOR, ATEX

CAPSCREW, HEX SOC HD

M6 X 1.0 X 35

COVER

SEAL, O-RING

SEAL, O-RING

O-RING

CAPSCREW, HEX SOC HD

M6 X 1.0 X 25

CAPSCREW, HEX SOC HD

M6 X 1.0 X 25

CONNECTOR (Power

Generation Module to

Control Module)

CONNECTOR

(Control Module to Power

Generation Module)

CONNECTOR

(To Intermediate)

BREATHER

ASSEMBLY

WASHER, FLAT, M6

Do not open when an

explosive atmosphere

may be present.

WARNING

S u b s t i t u t i o n o f

components may

impair intrinsic safety.

WARNING

Note: Ensure all mating faces are free from scores or damage prior to

re-assembly. Check each metallic face joint with a 0.003" feeler gage

to ensure all flange faces are fully closed after assembly. Failure to do

so may compromise the flameproof design of the assembly.