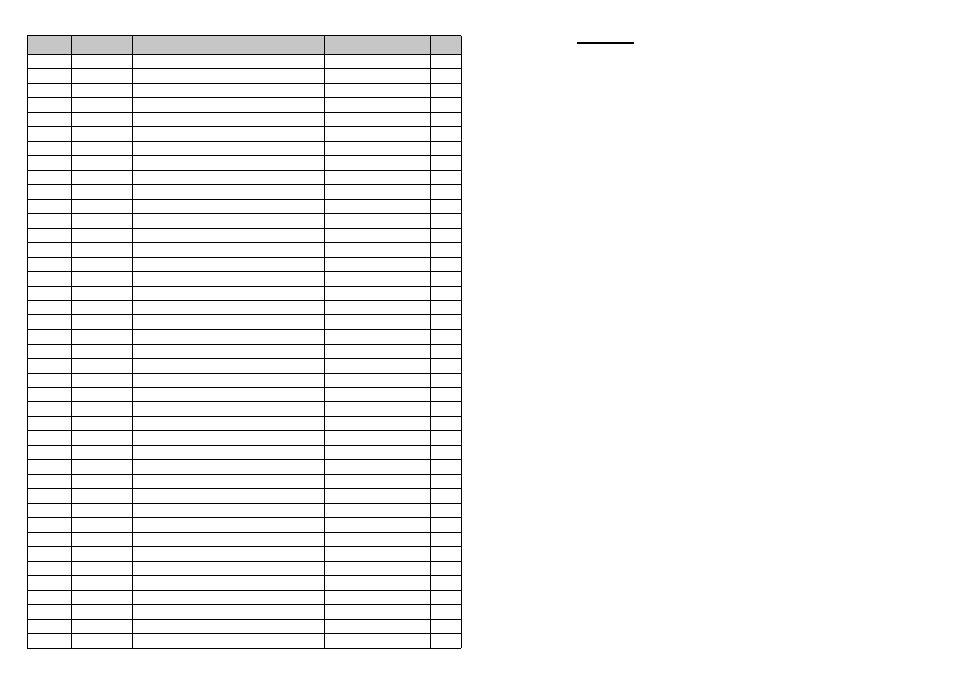

Parts list – Versa-Matic AP50 SUBMERSIBLE CENTRIFUGAL PUMP User Manual

Page 5

PARTS LIST

REF No

PART No.

DESCRIPTION

MATERIAL

QTY

1

AP50.60

STRAINER

S.G. IRON

1

2

AP50.55

VOLUTE

CAST IRON

1

3

AP50.57

IMPELLER

GUNMETAL

1

4

AP50.56

VOLUTE SHIM (0.010”)

PLASTIC

A/R

5

AP50.56A

VOLUTE SHIM (0.015”)

PLASTIC

A/R

6

AP50.52

SEAL

NBR/ST.STEEL

2

7

A135

HEX. HEAD BOLT - M10 x 25

HT. STEEL

4

8

AP50.51

BEARING HOUSING

CAST IRON

1

9

AP50.43

BUSH

MANGANESE BRONZE

1

10

AP50.42

BEARING NUT

STEEL PLATED

1

11

AP50.41

BEARING

STAINLESS STEEL

1

12

AP50.80

NAMEPLATE

BRASS

1

13

K076

HAMMERDRIVE SCREW - No6 x 3/16

STEEL PLATED

2

14

AP50.67

HANDLE

M.S. TUBE

1

15

A063

HEX. HEAD BOLT - M10 x 40

HT. STEEL

2

16

AP50.44

INTERMEDIATE SECTION

CAST IRON

1

17

AP50.33

LOWER BEARING PLATE

GUNMETAL

1

18

AP50.20A

DOWEL

HT. STEEL

4

19

AP50.25A

LOCATING SCREW

HT. STEEL

1

20

AP50.20

CYLINDER BODY

S.G. IRON

1

21

AP50.25

CYLINDER LINER

CAST IRON

1

22

AP50.29

ROTOR SHAFT

HT. STEEL

1

23

AP50.28

ROTOR KEY

KEY STEEL

1

24

AP50.13

FELT PLUG

FELT

1

25

AP50.15

ADJUSTING SCREW

HT. STEEL

1

26

AP50.09

LOCKSCREW

HT. STEEL

1

27

AP50.22

UPPER BEARING PLATE

GUNMETAL

1

28

AP50.23

CIRCLIP

HT. STEEL

1

29

AP50.19

LOWER GOVENOR SECTION

STEEL

1

30

AP50.18

BALL CAGE

ACETAL

1

31

AP50.17

GOVENOR BALL

STEEL

2

32

AP50.72

THRUST PAD

STEEL

1

33

AP50.07A

GOVENOR VALVE BALL

CARBIDE STEEL

1

34

AP50.04

GOVENOR CYLINDER

BRASS

1

35

AP50.05

O-RING

NITRILE

1

36

AP50.11

OIL FILLER PLUG

STEEL

1

37

AP50.12

WASHER

FIBRE

1

38

AP50.03

SPRING SPIGOT

BRASS

1

39

AP50.02

AIR FILTER

STAINLESS STEEL

1

40

AP50.207

HOSE UNION - NPT

STEEL

1

41

Z128

BLANKING PLUG

PVC

1

Pump Body

3.9 Remove governor housing and air motor as previously described.

Remove bolts (7) from volute (2) and lift pump body assembly

free.

3.10 Turn pump body over, lock impeller and remove nut (81) together

with impeller (3) from intermediate section (16).

3.11 Remove bolts (76) and withdraw bearing housing assembly (8)

from intermediate section (16).

3.12 Turn impeller shaft (74) and check for ease of movement and

quality of impeller bearing (11). Replace bearings as required.

3.13 To replace bearing (11), remove circlip (7) and withdraw impeller

shaft (74) from housing (8). Unscrew impeller nut (10) and

withdraw bearing (11).

3.14 Check impeller seals (75) and o-ring (6) for wear or damage,

replace as required. Ensure correct position of seals (75) so that

lips face the impeller.

3.15 If impeller is damaged or excessively worn, performance of the

pump will be reduced. When replacing, the impeller must be

adjusted to within 0.005" to 0.010" from the volute (2) internal

face for maximum efficiency. This is achieve by the addition or

subtraction of shims (4) & (5).

3.16 Re-assemble the pump as described above in reverse order. Ensure

all fittings are tight and secure before running the pump.