Val-Matic 2-42 Sure Seal Foot Valve User Manual

Page 3

2

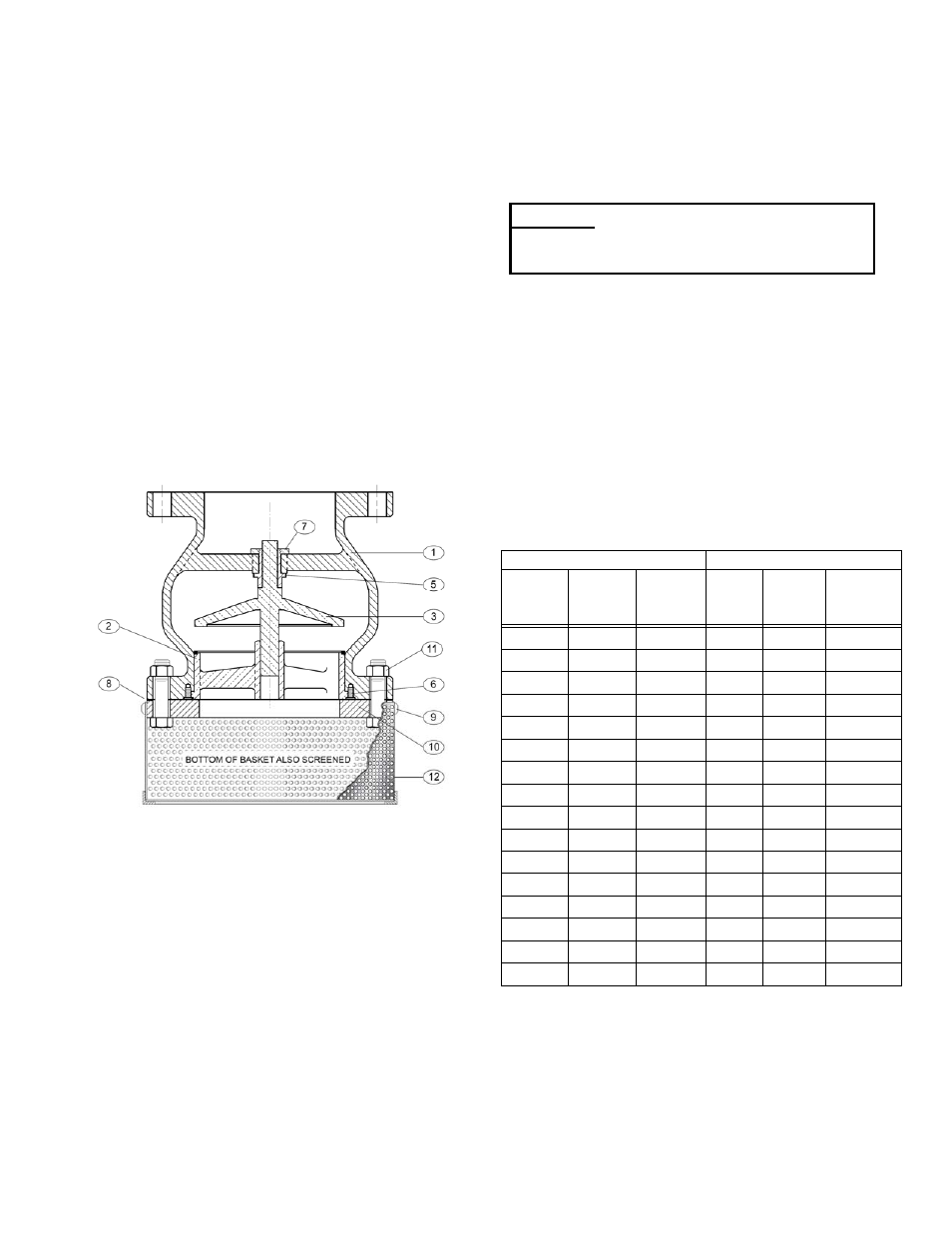

VALVE CONSTRUCTION

The standard Series 1900 Foot Valve is constructed

of rugged cast iron with a bronze or stainless steel

trim. See the specific Materials List submitted for

the order if other than standard cast iron

construction. The details of construction are

illustrated in Figure 2.

The body (1) is furnished with a flanged outlet for

bolting to the suction piping. The body is equipped

with a bronze seat (2). The disc (3) is guided by a

bronze bushing (7) fixed in the body. Leak-tight

closure is made when the resilient seal located (6) is

compressed by the closed disc. A stainless steel

basket assembly (12) prevents debris from entering

the valve.

The only moving parts in the valve are the plug and

spring. The body bushing controls the movement of

the plug and assures that the plug contacts the seat

evenly. The valve has a resilient seal for drop tight

service.

FIGURE 2. FOOT VALVE CONSTRUCTION

INSTALLATION

The installation of the valve is important for its

proper operation. Some general recommendations

follow.

The flow direction is vertical flow up. Orient the

valve so that the basket is in the wet well or water

source. The basket lower surface should be at least

.75 times the valve diameter from the bottom of the

wet well floor or consult the pump manufacturer for

direction.

CAUTION: DO NOT INSTALL THE VALVE IN

HORIZONTAL PIPING OR SLAMMING MAY

RESULT.

The valve should be mated to ANSI Class 125# flat-

faced flanges equipped with resilient gaskets. When

ring gaskets are used, the bolt material shall be

ASTM A307 Grade B or SAE Grade 2 Carbon Steel.

Higher strength bolts may only be used with full-face

gaskets.

Lower valve into line using slings or chains around

the valve body. Lubricate the flange bolts or studs

and insert them around the flange. Lightly turn bolts

until gaps are eliminated. Recommended lubricated

torques for use with resilient gaskets (75 durometer)

are given in Table 1.

The torquing of the bolts should then be done in

graduated steps using the cross-over tightening

method. If leakage occurs, allow gaskets to absorb

fluid and check torque and leakage after 24 hours.

Do not exceed bolt rating or crush gasket more than

50 per cent of its thickness.

125# FLANGE DATA

250# FLANGE DATA

Valve

Size

(in)

Bolt

Dia.

(in)

Bolt

Torque

(ft-lbs)

Valve

Size

(in)

Bolt

Dia.

(in)

Bolt

Torque

(ft-lbs)

2.5 5/8

25-75

2.5 3/4

25-75

3 5/8

25-75

3 3/4

35-75

4 5/8

30-90

4 3/4

50-150

5 3/4

30-90

5 3/4

70-150

6 3/4

30-90

6 3/4

70-150

8 3/4

40-120

8 7/8

90-200

10 7/8

45-150

10 1

110-300

12 7/8

65-200

12 1

1/8

160-450

14 1

80-250

14 1

1/8

140-450

16 1

90-300

16 1

1/4

180-600

18 1

1/8

100-350

18 1

1/4

190-600

20 1

1/8

120-450

20 1

1/4

220-600

24 1

1/4

150-500

24 1

1/2

350-900

30 1

1/4

180-600

30 1

3/4

500-1500

36 1

1/2

250-750

36 2

700-2000

42 1

1/2

300-900

42 2

800-2500

TABLE 1. FLANGE BOLT TORQUES

C CAUTION:

Mating flanges must be flat faced

or damage to the valve may

result.