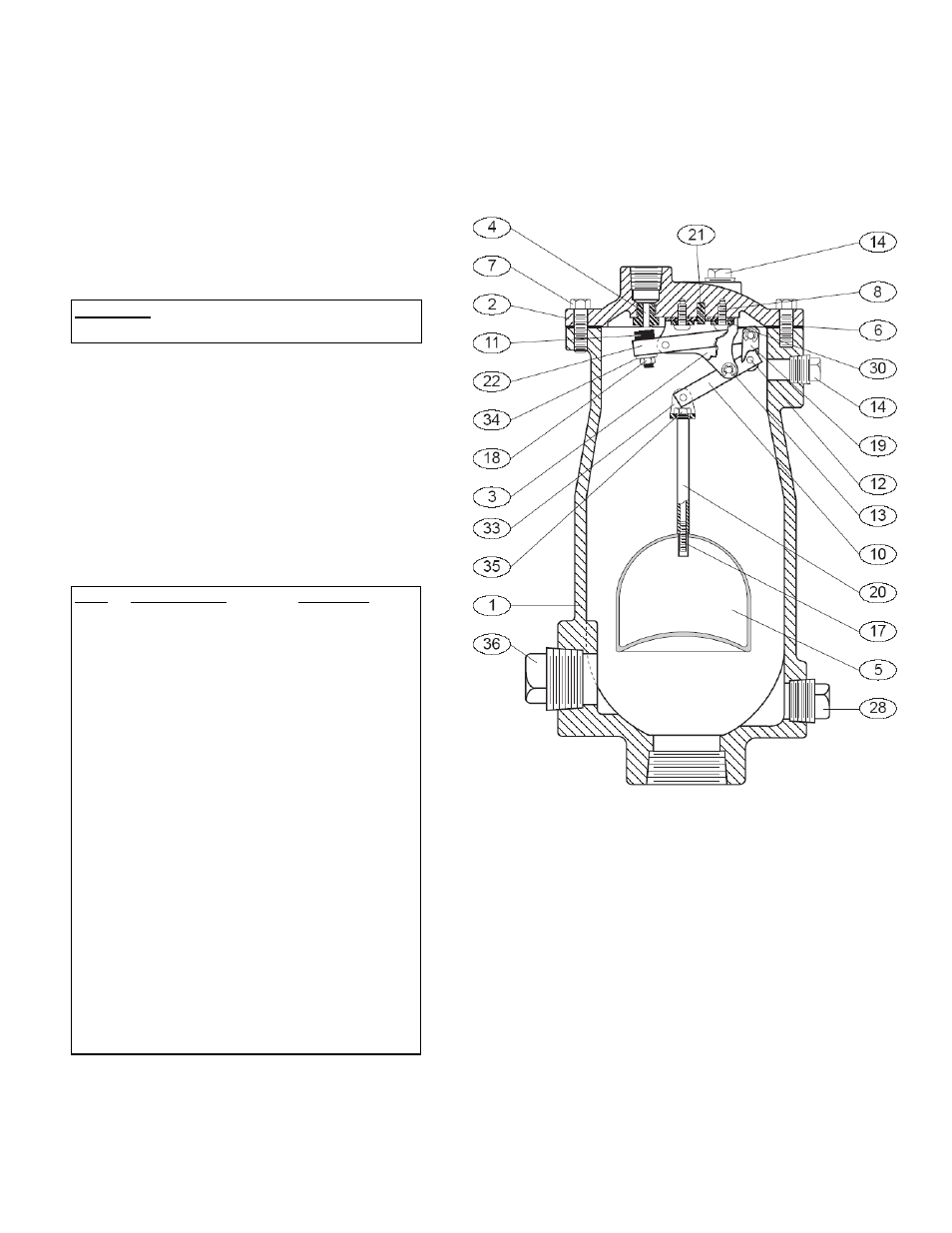

Installation, Valve construction – Val-Matic 49A Wastewater Air Release Valve User Manual

Page 3

2

CAUTION:

Install valve with "INLET" port

down or leakage will occur.

ITEM DESCRIPTION

MATERIAL

1

Body

Cast Iron

2

Cover

Cast Iron

3

Leverage Frame*

Stainless Steel

4

Seat*

Stainless Steel

5

Float*

Stainless Steel

6

Gasket*

Non-Asbestos

7

Cover Bolt

Alloy Steel

8

Retaining Screw*

Stainless Steel

10

Float Arm*

Stainless Steel

11

Orifice Button*

Buna-N

12

Pivot Pin*

Stainless Steel

13

Retaining Ring*

Stainless Steel

14

Pipe Plug

Iron

17

Float Retainer*

Stainless Steel

18

Lock Nut*

Stainless Steel

19

Link*

Stainless

Steel

20

Extension Shaft*

Stainless Steel

21

Locating Pin

Stainless Steel

22

Orifice Button Arm*

Stainless Steel

28

Pipe Plug

Malleable Iron

30

Washer*

Stainless

Steel

33

Clevis*

Stainless

Steel

34

Lock Washer*

Stainless Steel

35

Retaining Screw*

Stainless Steel

36

Pipe Plug

Malleable Iron

*RECOMMENDED REPAIR PART KIT

INSTALLATION

The installation of the valve is important for its

proper operation. Valves must be installed at the

system high points in the vertical position with the

inlet down. For pipeline service, a vault with freeze

protection, adequate screened venting, and

drainage should be provided. During closure, some

fluid discharge will occur so vent lines should extend

to an open drain area in plant service. A shut-off

valve should be installed below the valve in the

event servicing is required.

VALVE CONSTRUCTION

The standard Wastewater Air Release Valve body

and cover are cast iron. See the specific Materials

List submitted for the order if other than standard

cast iron construction. All internal components are

stainless steel with the exception of the orifice button

which is resilient. The general details of

construction are illustrated in Figure 2. The body (1)

is threaded for connection to the pipeline. The seat

(4) is threaded into the cast cover (2).

TABLE 1.

LIST OF PARTS

FIGURE 2. WASTEWATER AIR RELEASE VALVE